Environmental stress screening (ESS)

Environmental stress screening - ESS - is also commonly referred to as temperature-controlled testing, or ‘shake and bake’, is a form of testing where products are subjected to high or low temperatures or to cyclical temperature fluctuation, while being shaken, to ensure that the combination of thermal and vibration stress does not cause the product to fail.

Environmental stress screening is a way of proving operational stability at extremes, such as desert conditions, hot manufacturing environments or very cold weather. Test types include highly accelerated lifetime testing (HALT) and highly accelerated stress screening (HASS).

ESS is common for military products and components that often operate at extreme temperatures and for industrial products such as automotive components – both engine components and in-cabin assemblies. For military products, the testing temperature range is –55 °C to +125 °C. For industrial products, the common range is –40 °C to +85 °C.

System suggestion

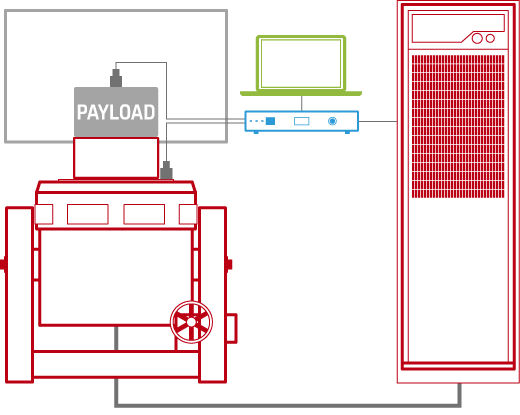

To perform environmental stress testing, a shaker – for example, a V875 (or V8750 - coming soon) with a thermally-conditioned fixture and a thermal barrier – is fitted to an environmental chamber so that only the payload and the shaker fixture are inside the chamber. Depending on the type of test, the shaker can be in vertical or horizontal configuration.

The LASERUSB controller supports standardized testing, including testing according to MIL-STD-810 and DEF STAN 00-35.

Iscriviti alla nostra Newsletter e ricevi le informazioni più recenti dal mondo del suoni e delle vibrazioni