With its headquarters in Southern Australia, Manta Controls develops unique advanced control systems to help optimize semi-autogenous grinding (SAG) mills. SAG mills are primarily used at gold, copper and platinum mines where steel balls are used for the grinding.

The Manta Controls Advanced Control System, called the SAG Cube, automatically monitors and controls a SAG Mill, keeping track of critical process variables impacting mill throughput. For most sites, one hour of operation provides a revenue between AUD$ 20,000 per hour up to or greater than AUD$ 100,000 per hour. Therefore, any downtime is very costly.

John Karageorgos, Managing Director of Manta Controls, explains the latest challenge: “In essence, we are trying to listen to a grinding mill and measure when the mill can be damaged from the steel balls hitting the steel liners of the mill. If we have a reliable measure of ‘damage’ then we can control the mill and not operate in the damaging mode.”

LEARN MORE:

TYPE 2250

SOUND LEVEL METER

A New Approach to Analyzing Acoustic Emissions

The answer to the challenge turned out to be a new generation of SAG mill acoustic analyzer, the Manta Mic, which takes advantage of Brüel & Kjær’s products for analyzing acoustic emissions. However, it wasn’t a straightforward development process.Manta Controls had previously been using a Type 2238 sound level meter.

“We have been working directly with Brüel & Kjær for two years, but working with Brüel & Kjær equipment for the past 20 years,” explains John Karageorgos, and continues: "Brüel & Kjær provides the ‘Rolls Royce’ of equipment with regard to anything acoustic, and we rely on it to be reliable and robust.

When Type 2238 became obsolete, Manta Controls looked to Type 2250 to replace it:

“The only catch was that we lost our capability of having a 4–20 mA signal because Type 2250 had an Ethernet connection,” explains John Karageorgos.

One key objective of the new solution was to eliminate the need for a computer from the architecture; Manta Controls invested approximately AUD$ 200 k in R&D to find a robust solution to communicate with Type 2250 directly from a control system, without a computer connected to Type 2250.

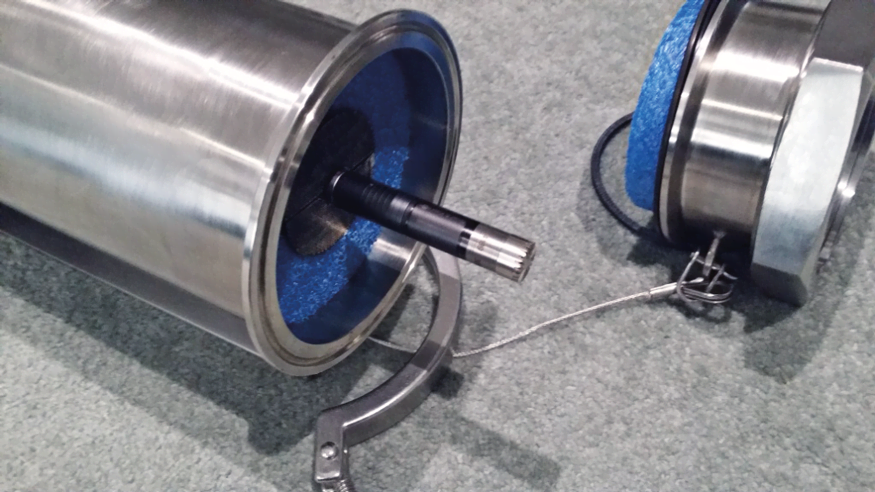

The new rugged Manta Mic holder showing the Brüel & Kjær preamplifier and microphone.

LEARN MORE

MEASUREMENT MICROPHONES

MICROPHONE

PREAMPLIFIERS

Research Pays Off

“When we started this project, no one knew if it was achievable, so in the beginning, it was pure research work. We were prepared to try and then walk away if it didn’t work. That’s the risk with developing anything new,” explains John Karageorgos.

After almost 12 months of development, things were not going so well and the research team had not managed to communicate directly with a Type 2250 from a control system without having a computer as a gateway. John Karageorgos explains:

“We were nearly ready to pull the pin on the project, but we gave it one last chance. We tried a new idea, and we finally got the control system to communicate with Type 2250, directly. I will never forget that day! Once we did that, we knew we had a product!”

Unexpected Discovery

By solving a particular problem with the communication to Type 2250, Manta Controls discovered something new:

“We then managed to pull through the entire frequency spectrum from Type 2250 directly into a control system with no computer being used as a gateway or interface. This has never been done before with Type 2250."

This discovery has started a new R&D project where Manta Controls are trying to use the live data to monitor operating conditions, such as the optimum volumetric percentage filling and the condition of the lifters. This could also be deployed on other mining equipment as well, not just on SAG or AG mills.

Protecting and Optimizing Mills

The main benefits of this type of reliable SAG mill monitoring are accurate and repeatable decibel signals at the various frequencies – information that is used to protect the mills. The next phase of the project is to provide measurements that can help customers operate a SAG or AG mill optimally.John Karageorgos explains: “Optimization is our bread and butter, so once we have the measurements we are looking for, incorporating them into our SAG Cube solution is easy. The hard part is developing these new operating parameters that tell us whether a mill is operating optimally or not.”

Future Possibilities

Manta Control customers seem pretty excited about the new solution because it offers capabilities that were simply not possible before.

“Now we can offer a simple and elegant yet robust solution with the added benefit of the quality that Brüel & Kjær equipment provides. This has also opened the door to some new ideas. We have plans to further develop the solution to offer additional capabilities.

For example, we are looking at capturing even more data with two microphones to monitor two locations, and then we’ll try an array of microphones. "And, we are also looking at using Brüel & Kjær accelerometers on other applications – but we are keeping them to ourselves for the time being!” concludes John Karageorgos.

Abonnez-vous à notre Newsletter et recevez les dernières actualités en acoustique et vibrations