Type 9737

Portable Impedance Meter System

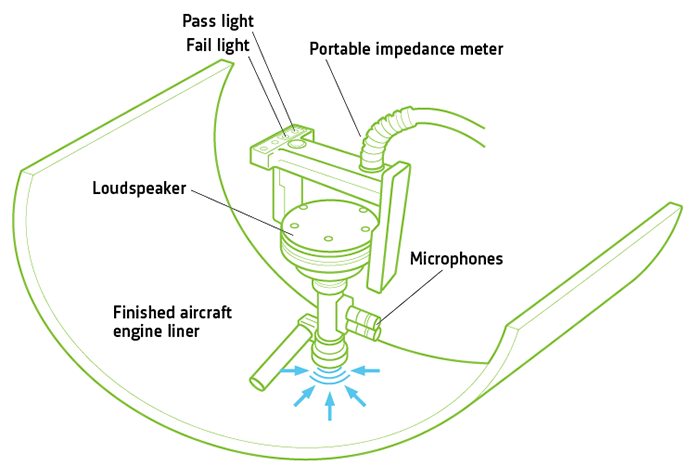

Portable Impedance Meter System Type 9737 delivers state‐of‐the‐art normal incidence impedance measurements for the aerospace industry.

견적 요청하기Portable Impedance Meter System Type 9737 makes fast measurements of the acoustic properties of materials without having to remove a material sample.

The impedance meter consists of an easy-to-use hand-held instrument, a LAN-XI data acquisition front end, and PC software. Because it can measure objects in situ, it is ideal for verification after installation of acoustic treatments, and for quality control after all manufacturing processes are complete.

USE SCENARIOS

- Quality assurance checks of aircraft engine nacelle liners on the production line

- Measuring acoustic properties of aircraft interiors and cabin trim materials, such as attenuation and transmission loss

- Evaluating sound insulation material installations in wind tunnels for aerospace or automotive research

- Standard coupon tests using material samples to establish transmission loss, such as for automotive sound deadening materials

The instrument has a sound source activation switch and status indicator integrated in the handle. An automated pass/fail routine allows production line operators to simply hold the instrument in contact with the in situ test article, and then receive a clear go/no go signal from an LED.

Measurements are also viewable on a PC in real-time for ease of monitoring. The PC software has dedicated routines for measuring key quality control parameters.

CHARACTERISTICS

The kit consists of a hand-held impedance tube which contains two microphones, a sound source, and integrated sensors to measure temperature, pressure and relative humidity. This is connected to a single front-end unit consisting of a LAN-XI generator module and power amplifier, which is conveniently housed in a double LAN-XI casing.

The flat flange is designed for optimal sealing, and is removable so you can replace it with custom-built curved flanges, for maximal sealing to contoured panels such as fully bonded panels in aircraft acoustic liners, in their final condition.

CAPABILITIES

- Up to 155 dB SPL

- 29 mm inner diameter tube, sized for optimum performance between 500 Hz and 6400 Hz, can be combined with optional wider tubes for measurements down to 50 Hz

- Measurements on complex or composite materials, and orientation-sensitive materials

- Measurement with broadband, pure-tone, or user-defined source

- Calculation of non-linear resistance variation with acoustic velocity

- Option to loop on increasing OASPL or Pure Tone SPL

- In-tube sample holder for flanged tube correction routine

Acoustic parameters are extracted in situ, such as:

- Impedance spectra vs overall sound pressure level (OASPL), and acoustic resistance vs acoustic velocity

- Acoustic pressure and acoustic velocity spectra at sample surface

- Acoustic absorption coefficient

- Acoustic reflection coefficient

- Normalized impedance and admittance

- Acoustic resistance as a function of acoustic velocity

- Acoustic velocity as a function of frequency

- Acoustic effective open area (acoustic POAeff) for single-layer perforate panels

- Acoustic R105, NLF characteristics for single-layer linear and multiple-degree-of-freedom panels

Results are directly exportable to Microsoft® Excel® and/or Microsoft® Word.