DISCOM

DISCOM Noise Analysis for Gear Test

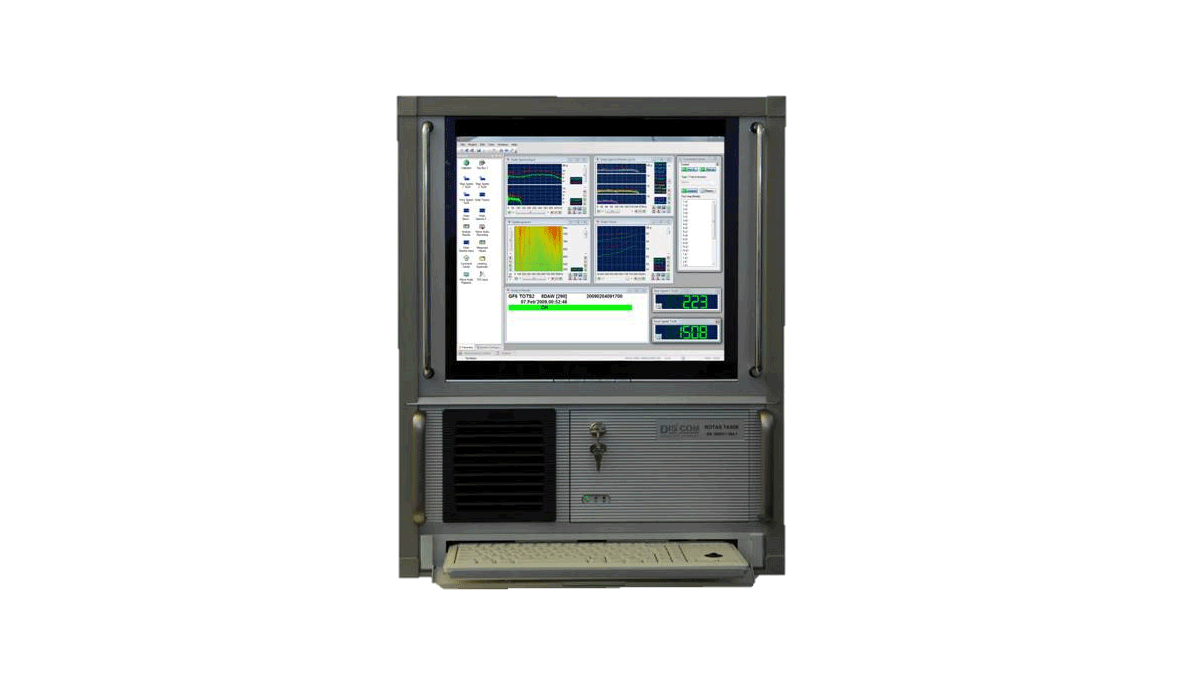

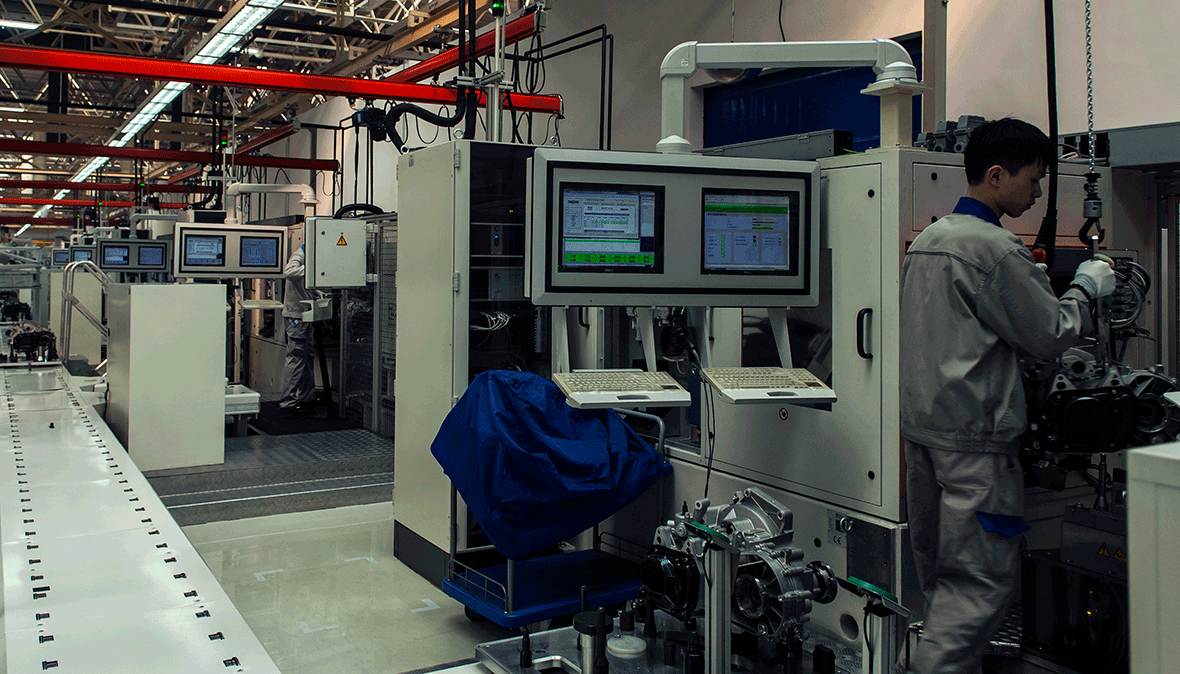

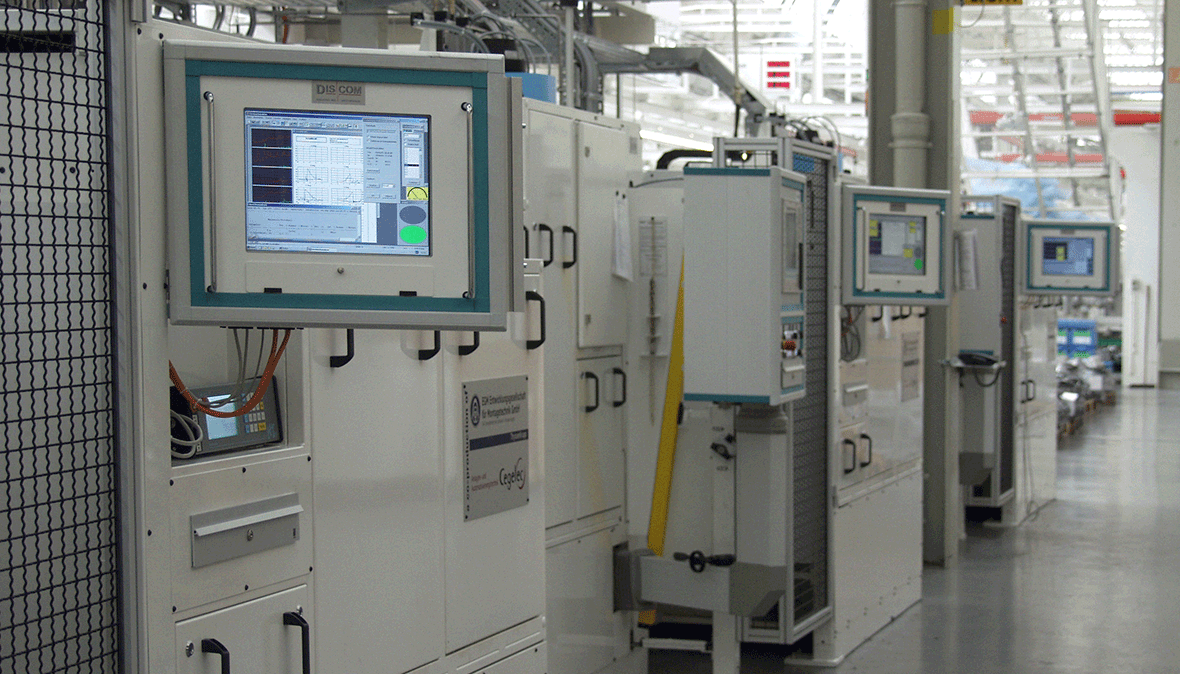

DISCOM Noise Analysis for Gear Test is a complete acoustic quality, end-of-line test system for gears. The system includes transducers, data acquisition hardware, and analysis and database software.

Demande de devisDISCOM Noise Analysis for Gear Test is a pass/fail acoustic noise analysis quality assurance (QA) system comprising data acquisition hardware and analysis and database software. The system automatically sorts gears based on their pass/fail condition, with any failing gears sorted to be reworked or melted down and remade. The system can be configured for single- or double-flank testing and, because the system is modular, it can be easily scaled to match the product and production-line complexity by, for example, adding an additional front end to accommodate additional transducers.

USE SCENARIOS

- End-of-line pass/fail testing for gears

- Single- or double-flank testing

- Trend/tool-wear analysis

- Root cause of failure analysis

- Outgoing quality control

CAPABILITIES

- Rotationally synchronous analysis

- Nick and surface wave (ripple) detection

- Geometry errors (eccentricities, shape deviation, tooth spacing, etc.)

- Time-domain history

- Single-value statistics

- Order spectra and order tracking

- Modulation and ticker analysis

The system also includes access to the knowledge and experience of expert technicians and engineers who work with you to provide the best test configuration for your production line, hardware installation, software setup and configuration, and ongoing parameter refinement.

All data is stored in databases that, when analysed, can be used to continuously refine test parameters, and eliminate root causes of failures and identify and predict trends.

Abonnez-vous à notre Newsletter et recevez les dernières actualités en acoustique et vibrations