NVH - Vehicle noise, vibration and harshness

The combined noise, vibration, and harshness - NVH - become immediately apparent when car drivers assess the ‘feel’ of a vehicle. In this article, we take a look at what NVH means to automotive manufacturers and customers, and how NVH simulation enables test engineers to optimize noise, vibration, and harshness in vehicles.

Noise, vibration, and harshness (NVH), also referred to as noise and vibration (N&V), is the study and adjustment of noise and vibration characteristics in vehicles, particularly cars or trucks. While noise and vibration can be readily measured, harshness is a subjective quality. Sound quality as a NVH parameter can be subject to jury evaluations, or evaluated with electroacoustic equipment, reflecting human subjective impressions.

A car that rattles or a motorbike that vibrates are tiring and annoying to use, and on longer journeys, the comfort of good NVH is one of the strongest brand differentiators. NVH performance is a necessity for luxury vehicles; as any edges they can gain over competitors will pay back handsomely in brand equity and loyalty.

NVH Testing: Optimizing Noise and Vibration

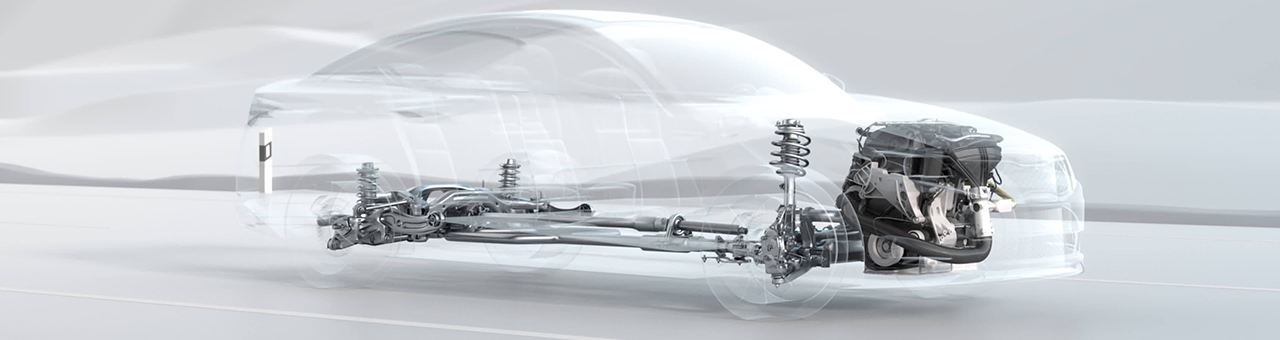

Vibration energy from an engine travels through the engine mounts, into the structure, and through the car seat into the driver. But energy from the same source can take a similar path through the structure to become acoustic noise when it is amplified by the cabin.

Optimizing these factors is therefore of utmost importance for the overall experience of the vehicle.

Computer-Aided Engineering (CAE)

CAE and test departments alike must endeavour to deliver a smooth, quiet vehicle. This is true no matter what the project – from a standard model iteration to developing a new, cutting-edge vehicle design with relatively untried, innovative propulsion, such as hybrid electric powertrains. Moreover, designers have their hands tied by emissions restrictions and face ever-shortening development time frames.

Brüel & Kjær offers tools to provide insight into NVH processes and break sounds down into their component sources and the paths they take. This is true for both the NVH test engineer and CAE analysis alike. And we bridge the gulf between them by auditioning NVH with highly authentic simulators throughout development.

-

NVH Simulation

NVH simulation enables managers and customers alike to ‘drive’ rival vehicles and previous models in highly realistic scenarios so engineers can quantify their opinions.

-

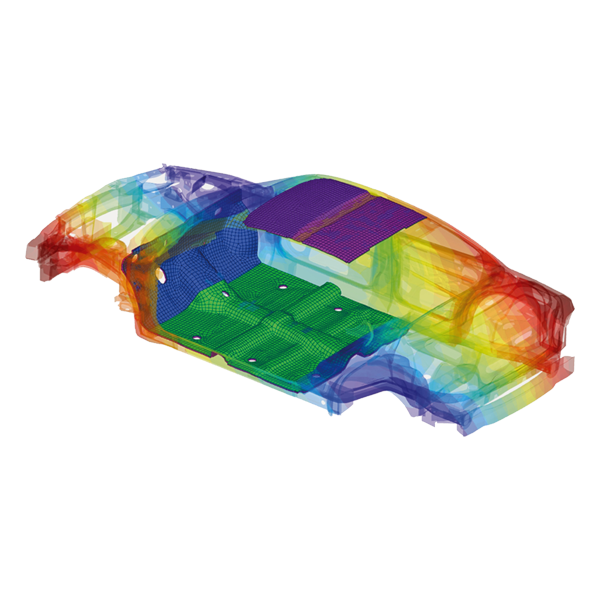

CAE Simulation

NVH product development has transitioned from paper-and-pen drafted designs to a computer-aided drafting (CAD) environment. This enables CAE Simulation for earlier vehicle testing and faster, less costly redesign.

-

Source Path Contribution - SPC

Identifying the sources of the vibroacoustic emissions that we both hear and feel is essential to creating comfortable vehicles.

Subscribe to our newsletter and receive the latest stories from our world of sound and vibration