Vibration testing and validation

By condensing a lifetime of stress and wear into a short period of time, vibration testing and validation can reveal hidden design weaknesses. Vibration testing helps manufacturers to ensure quality, reliability and durability of complete products and their components by providing insights into the inner world of vibration within products, machines and structures.

Ask an expertTo ensure products can handle shocks and stresses within their service life, vibration testing comes into play. As an example, this applies to:

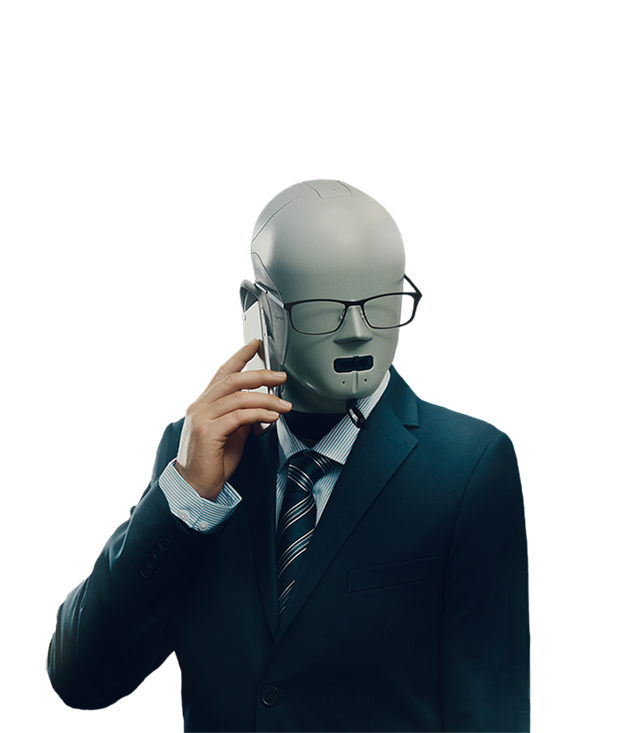

- A mobile phone must be able to withstand bouncing around in a backpack as well as being dropped on the floor several times. If it cannot cope with this general day-to-day use, warranty costs will explode for the manufacturer resulting in a real risk of brand deterioration and of customers looking elsewhere the next time they buy a new phone.

- A satellite has to be able to survive the excessive vibrations from being launched into space. If it is faulty, the investment in the development and building of the satellite may be jeopardized.

In order to ensure that the products customers receive are intact and fully-functional, it is essential that they can survive the journey from when they are boxed at the factory until they arrive at the end destination. Moreover, beyond merely withstanding short-term physical forces, developers need to ensure that their products will maintain the integrity and quality that represents the brand in the longer term.

Product qualification and verification is done through extensive simulation in the development phases, but simulation is not enough. It is also necessary to do physical testing on prototypes and end-of-line items, both to validate simulated results and to prove product durability to customers.

Ensuring product quality

Vibration tests can reveal design weaknesses that would only become apparent during transport, deployment and use – like a helmet hitting the ground. Some of these tests, such as buzz, squeak and rattle (BSR) on vehicle interiors, can also detect the development of unwanted noise.

For environmental testing such as highly accelerated lifetime testing (HALT) and highly accelerated stress screening (HASS), it is necessary to combine vibration testing with environmental chambers to add the expansion stresses of rapid heating and cooling. These tests are typically conducted on industrial and electronic components and products, on medical equipment and on military hardware.

Vibration test profiles

Where do the actual vibration test profiles originate? Customers, end users or manufacturers who incorporate a component into an assembly, often define vibration test specifications and procedures themselves.

These are typically based on experience and knowledge of which design solutions work well and which don’t. Vibration testing can provide a more structured approach to understanding failure modes and defects that are caused by vibration.

Vibration testing standards

Many vibration testing profiles are defined by standards developed over many years. There are a lot of them and they are often dedicated to specific applications and products. Examples include DIN, ISO, BS, MIL, IEC and ASTM. The use of testing according to standards is especially the case for the aerospace and defence industries. These include MIL-STD-810, NATO STANAGs and AS/EN9100.

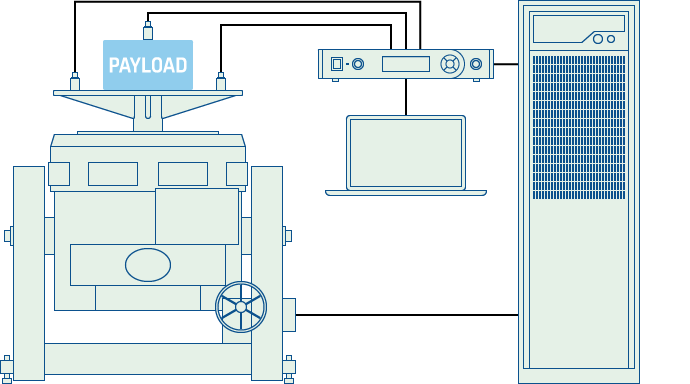

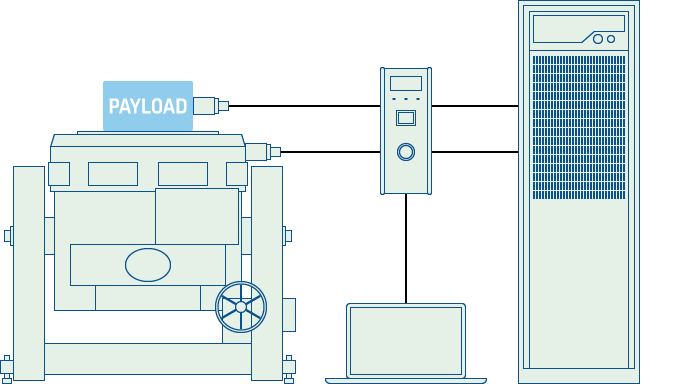

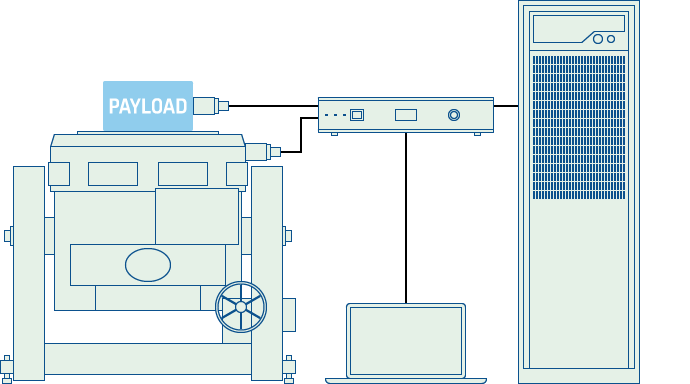

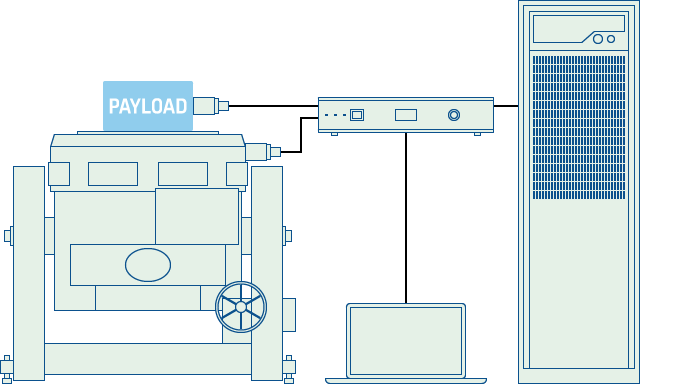

Selecting a vibration test system

It is essential that your system is appropriate for the test – able to input the necessary vibration types and able to handle the forces generated when testing specific payloads. Above all, self-monitoring of resulting vibration levels is vital to ensure that your test object is not stressed more than necessary.

There are many ways of configuring systems to meet your testing requirements. If your requirements are not met by these specific suggestions, please explore the vibration testing equipment page or contact your local Brüel & Kjær sales representative to discuss your needs.

-

Durability Testing - Fatigue Testing

Durability and fatigue testing help manufacturers to evaluate how well their products and components hold up to typical use.

-

Shock and Drop Testing

When conducting shock tests, payloads such as televisions are moved rapidly for a short time period 100 g or 11 m/s, to simulate a car hitting a pothole or a television being dropped under transport.

-

Package Testing / Transport Vibration

Package testing and transport vibration simulation is designed to simulate a product’s journey from when it is boxed at the factory until it reaches the customer.

-

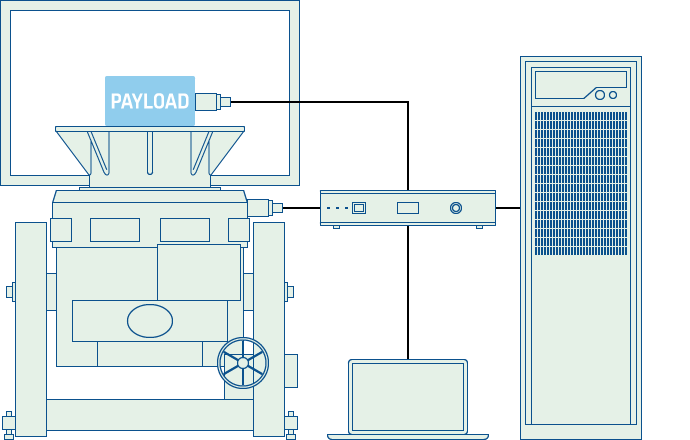

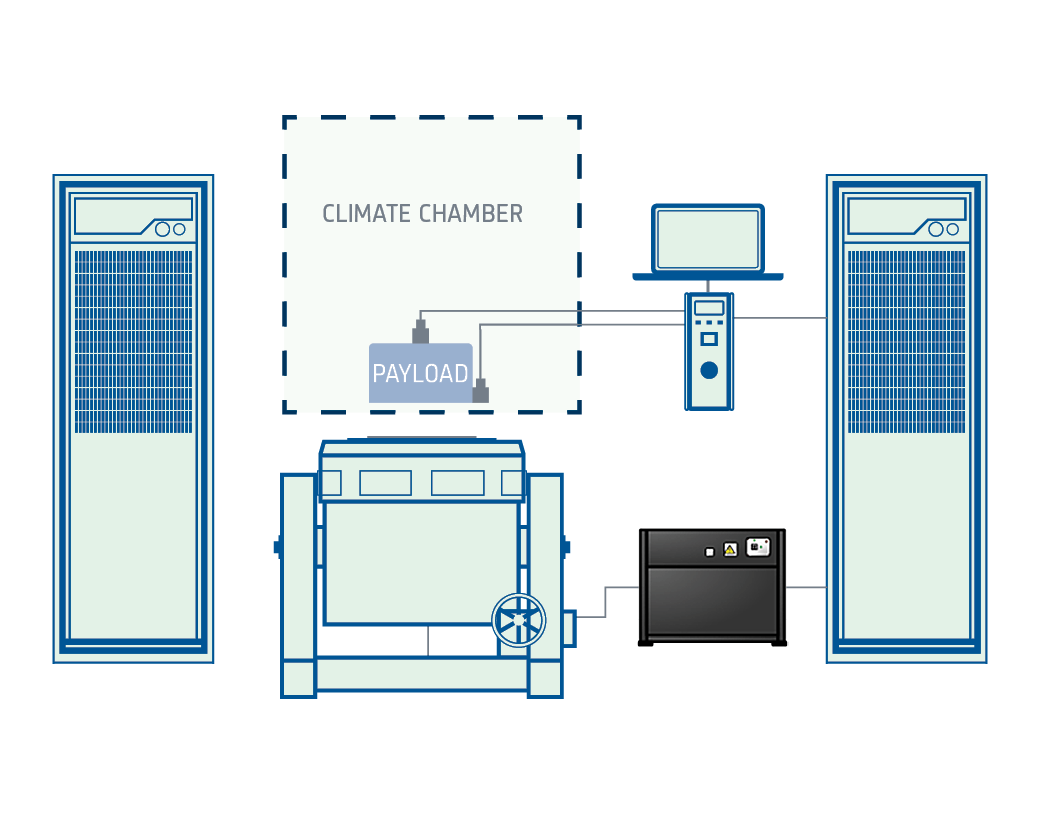

Environmental Stress Screening - ESS

Environmental stress screening is a form of testing where products are subjected to high or low temperatures or to cyclical temperature fluctuation, while being shaken, to ensure that the combination of thermal and vibration stress does not cause the product to fail.

-

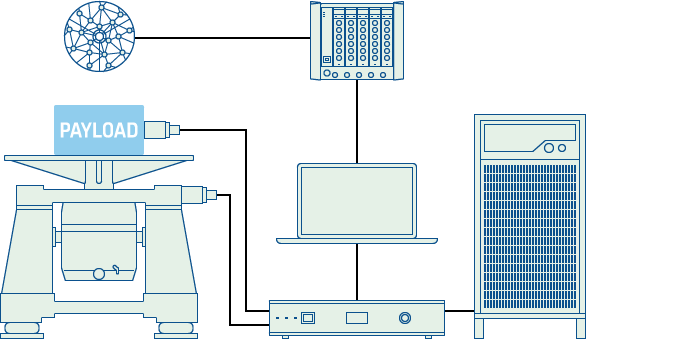

Electric and Hybrid Vehicle Battery Testing

Vibration testing of Electric Vehicle (EV) battery modules and packs, e-axles and e-drivetrains is performed during prototype development to validate product release for production.

-

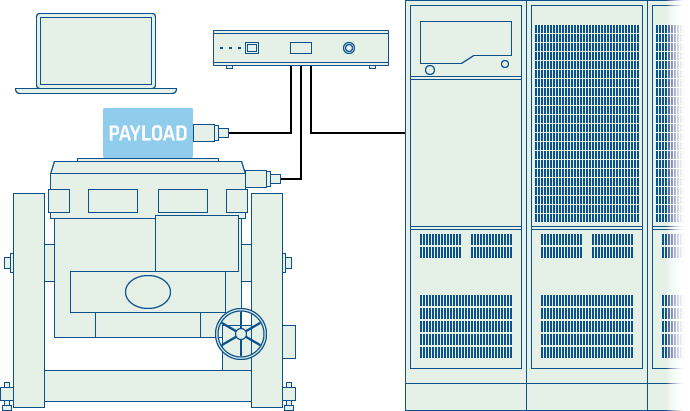

Mechanical Satellite Qualification

Qualification and acceptance testing (Q&A) ensures that equipment designs meet the performance expectations required for a particular mission – from assembly and transportation to launch and operation.

-

Buzz, Squeak and Rattle (BSR)

Buzz, squeak and rattle (BSR) testing is performed in NVH application and ensures automotive components and interiors remain durable and free from noise, for greater passenger comfort.

Parla oggi stesso con il tuo rappresentante locale Brüel & Kjær!