BK CONNECT TYPE 8405-F

Order Tracking Software

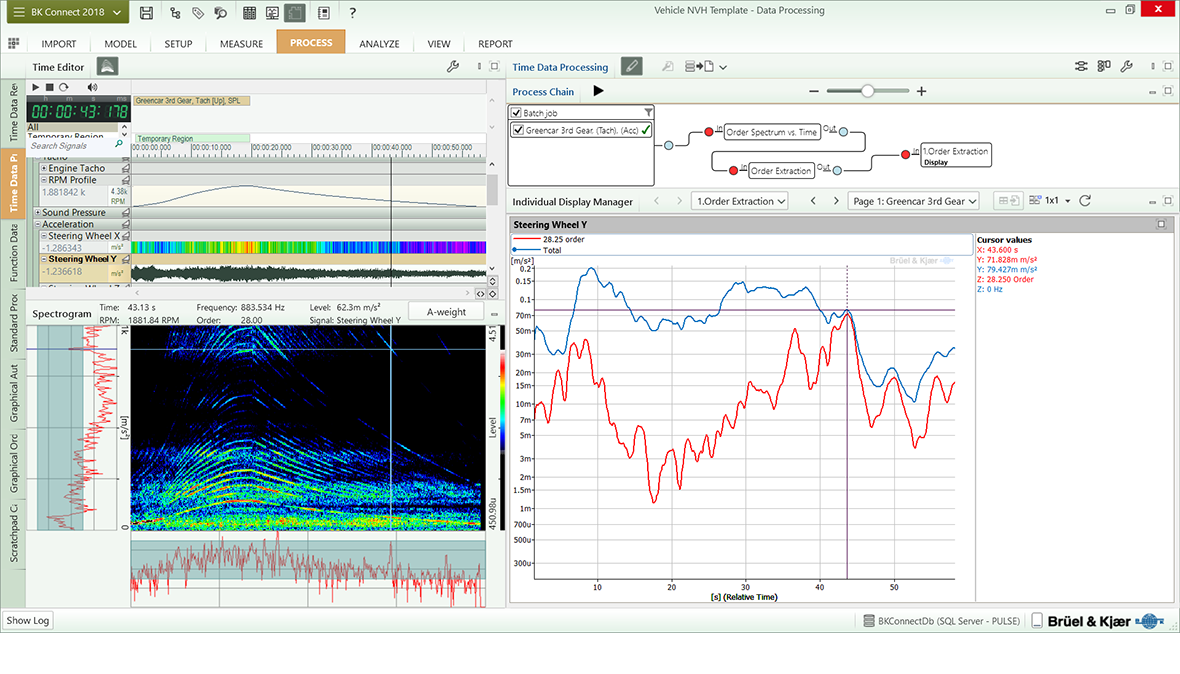

BK Connect® Order Tracking for advanced processing order analysis – relating noise and vibration signals to revolutions of rotating or reciprocating machine component.

Richiedi un preventivoThis BK Connect Order Tracking Type 8405-F performs analysis on sound and vibration signals, detecting patterns that are caused by inherent instabilities and imbalances in reciprocating or rotating machines.

By relating the sound and vibration data to revolutions of moving parts, this software improves the engineer’s ability to find its source.

ADVANCED CAPABILITIES

This option allows advanced processing and tracked resampling. This calculation tool, in conjunction with Type 8405-E spectra-based order analysis, is recommended for high-accuracy analyses of higher orders and fast speed sweeps.

USE SCENARIOS

- Highly accurate, leakage-free analysis of high-order numbers and fast speed sweeps in rotating machinery equipment such as gearboxes, transfer boxes, differentials, power trains, turbines and aircraft engines

- Root-cause analysis of tonal sound quality issues in prototypes

- Separating rotational and structural noise and vibration in products for noise source location

- Determining critical speeds and resonances during vehicle or engine speed sweeps (run‐up/down)

- Vehicle noise, vibration and harshness (NVH) tests such as benchmarking

For analysis of higher orders and slew rates, when RPM ranges are wide and when orders are not well separated, order analysis requires tracking: relating vibration signals to an RPM reference. The software supports the use of a tacho signals as a reference to compare to the sound and vibration data. An autotracker feature can also extract the revolutions directly from the measured vibration signals. The time data is resampled according to the instantaneous RPM value from a given tachometer signal.

CAPABILITIES

This option allows tracked resampling, which enables:

- Automatic processing of time data recordings

- Powerful batch processing of multiple recordings

- Order spectrum and order vs RPM

- Graphical order extraction tool

- Tachometer dropout/spurious pulse correction

- Tachometer repair: smoothing and pulse drop‐out, or multiple pulse correction

- Autotracker gives tachometer pulse train synthesis from RPM and speed profiles

CHARACTERISTICS

- Graphical, drag-and-drop analysis process chain

All BK Connect analyses use a graphical process-chain concept for setting up the post-recording analysis process. This includes individual elements for filtering, analysis, display and storage of results. each is individually configurable. Process chains can be exported to a file and emailed to allow others to repeat a defined, standardized process. - Automated processing

To maximize productivity, BK Connect enables batch processing of sequenced or parallel analysis of multiple sets of imported data. Time data can also be automatically imported from a network drive, and you even have the option of automatic reporting.