DISCOM

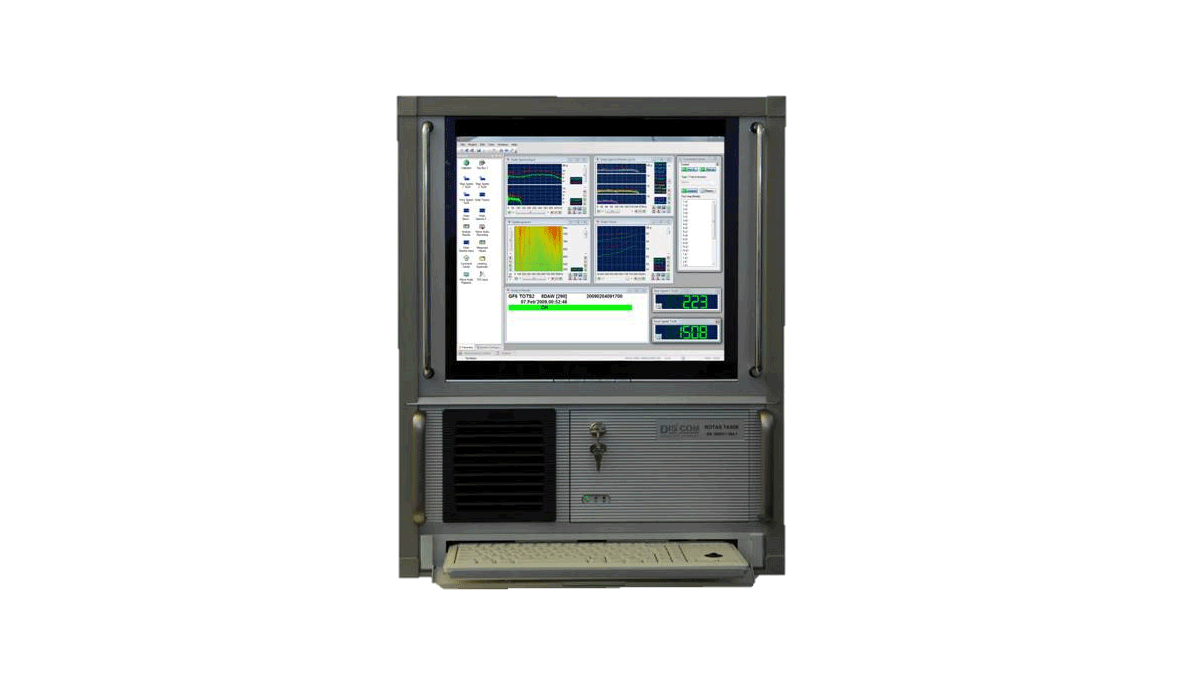

DISCOM Noise Analysis for Engine Test

Acoustic quality, end-of-line quality assurance test system for engines that comprises transducers, data acquisition hardware, and analysis and database software.

Solicitar ofertaDISCOM Noise Analysis for Engine Test is a complete end-of-line system that is ideally suited for testing engines – including internal combustion (IC), electric and hybrid designs. The system includes all transducers, data acquisition hardware and software specified for your test-stand and engine configuration.

USE SCENARIOS

- End-of-line testing for engines

- Hot or cold testing

- Root cause of failure analysis

- Outgoing quality control

Production lines and engine designs can vary greatly from one installation to the next, so DISCOM Noise Analysis for Engine Test has been designed to be modular and easily scalable. By adding additional transducers (including accelerometers, microphones or combinations of the two) or front ends, the system can be customized to match engine, test-stand and production-line complexity. The system also includes access to the expertise and experience of personnel who can ensure the ideal hardware installation, software setup and configuration, and ongoing parameter refinement.

CAPABILITIES

- Easily scalable to match the test environment and engine type and design

- Angular synchronous analysis

- Time-domain history

- Single-value statistics

- Order spectra and order tracking

- Detection of instationary events related to engine working cycle

All data from each test is stored in locally and remotely accessible databases. As part of DISCOM NVH Analysis, that data forms a complete and traceable data chain that enables easy identification and elimination of root causes of failures.

In addition, using DISCOM Mobile in a completed vehicle provides data for correlation with the test stands so that parameters can be refined based on noise or vibration that only presented in the fully assembled vehicle.

Suscríbase a nuestro boletín informativo y recibirá las últimas noticias de B&K sobre sonido y vibración