Wind tunnel testing For Cars

For many vehicle manufacturers, wind-tunnel measurements are the only way to recreate real-world conditions for testing model and mule cars. Wind tunnel testing for cars provides a verified method of validating simulated model data and allows the engineer to quantify the acoustic impact of noise-reduction treatments.

Ask an ExpertAerodynamic noise is particularly important for passenger car driving comfort and high-speed train community comfort. At cruising and higher speeds, the aerodynamic noise is the dominant noise source in a car, so in relation to car interior aerodynamic noise, measurements are performed on full size vehicles in wind tunnels at different stages during development.

Finding the source of acoustic phenomena can be done in many ways, and is often depends on the conditions in which the phenomena occur. To investigate exterior aerodynamic noise produced by high-speed trains, wind tunnel measurements are typically performed on scale models of train sections or on components such as pantographs.

System suggestion

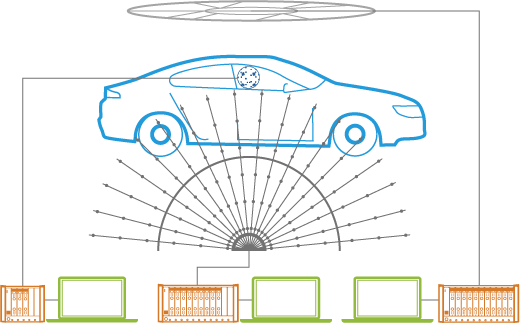

Our PULSE Array-based Noise Source Identification Solutions can withstand the tough conditions of wind tunnels and still acquire reliable data. They include the two main methods for measurement on the exterior of vehicles in wind tunnels – near-field holography and beamforming.

With beamforming, the array is placed relatively far from the source, outside the turbulent airflow. For near-field holography a scanning method can be used where an array of measurement microphones has to be placed close to the vehicle under test, usually within the airflow region. Available hardware includes planar and half-wheel arrays and Surface Microphone Type 4949, designed for measurement of the true surface pressure, is exceptionally well-suited for mounting directly on the car surface during wind-tunnel testing.

Iscriviti alla nostra Newsletter e ricevi le informazioni più recenti dal mondo del suoni e delle vibrazioni