Type 7758

Acoustic Material Testing Tube Software

For measuring the acoustical properties of noise control materials to ISO and ASTM standards, together with an impedance tube for material sample testing.

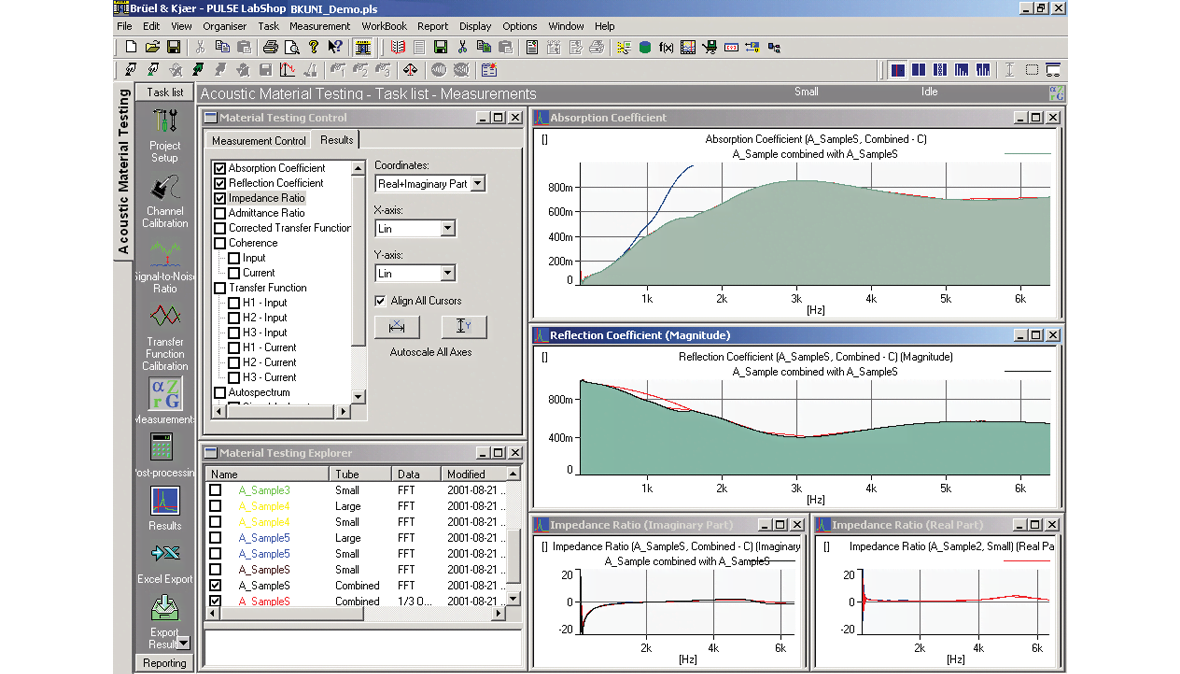

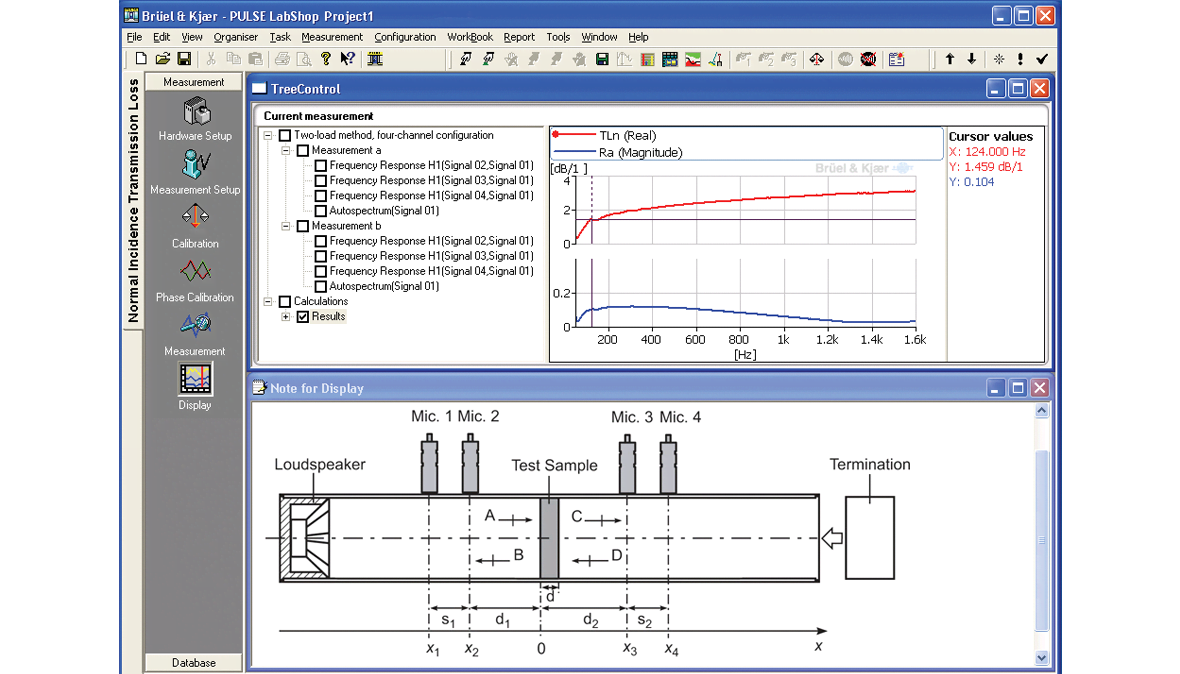

Request PriceThis PULSE™ software works together with a material testing tube such as an impedance tube or transmission loss tube. The user places samples of the material to be tested into the tube. A loudspeaker in the tube then emits precisely quantified sound, and microphones mounted along the inside surface of the tube measure the sound pressure level on both sides of the material. The software then calculates the acoustic properties of the material from the differences between the signals.

The software helps you determine sound absorption coefficient and surface impedance by making measurements and calculations that meet the standards ISO 10534-2, ASTM E1050 – 19, and ASTM E2611 – 17.

USE SCENARIOS

- Developing noise control products

- Designing acoustic comfort in aircraft and vehicle interiors

- Verifying material compliance with regulations

- Benchmarking competitive products

- Selecting the optimal acoustic treatment

- Validating and calibrating computational methods

- Automotive pass-by noise testing road surface absorption measurements

MATERIAL CHARACTERISTICS

Whether materials are intended to absorb airborne sound or reduce airborne sound transmission, the acoustic designer or acoustician needs to know the effects of the acoustic materials. A material sample, or coupon test, is a quick and convenient method. The impedance tube, or standing wave tube, guarantees highly reproducible testing conditions. Prior to testing, the signal-to-noise ratio (SNR) can be determined at each microphone position to ensure accurate results. The acoustic characteristics of materials are determined in terms of absorption, reflection, impedance, and admittance, including transmission loss.

MATERIAL TESTING APPLICATIONS

Early in the development process of vehicle interiors and aircraft interiors, designers aiming for acoustic comfort need to predict what the acoustical impact will be of components such as trim lining, headliners, seats, and multi-panel systems. This software and its associated hardware provides input to analytical and numerical tools for the prediction of the sound field in acoustic cavities such as vehicle cabins and aircraft cabins. These tools include finite element modelling (FEM) and boundary element method (BEM).

CAPABILITIES

- Dedicated software template for normal surface incidence sound absorption

- Dedicated software template for normal incidence sound transmission loss measurements

- Absorption coefficient, complex reflection coefficient, complex acoustic impedance, complex acoustic admittance

ADDITIONAL CAPABILITIES

- For tests that cannot use a material sample, such as after manufacturing processes have incorporated the acoustic material, or for in situ acoustic material tests, we offer a portable impedance meter system

- For automotive pass-by noise testing, this software is used to calculate the road surface sound absorption. It works with a dedicated testing tube from Brüel & Kjær

Measurement data and results can be conveniently saved to familiar Microsoft Excel® workbooks for customized reporting and further post-processing.