DISCOM analysis systems

DISCOM Analysis systems are acoustical quality analysis solutions customized to fit individual production lines. The effectiveness of the system stems from a combination of adaptable hardware and software set up to meet the needs of each production line, based on volume and complexity.

Using DISCOM Analysis Systems for end-of-line testing for component and finished product testing not only ensures the quality of each component and finished system, it provides the data needed to trace problems back to their root causes and eliminate them. The system identify patterns to solve the problem, and refine the prediction of cyclical problems like tool wear.

DISCOM NVH Analysis

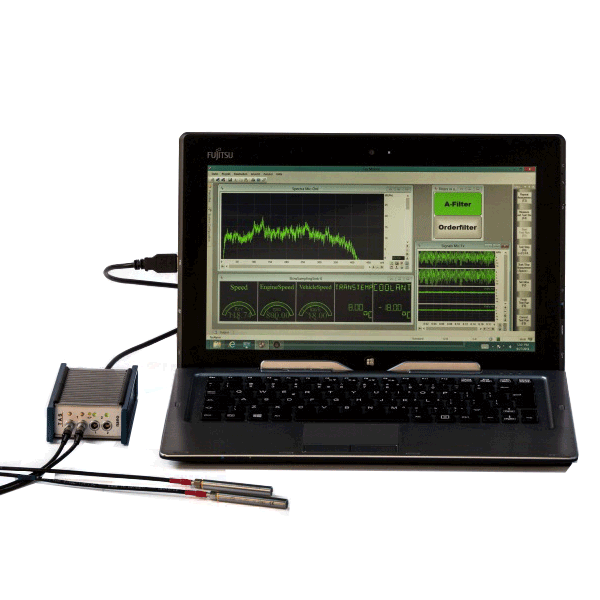

DISCOM NVH Analysis systems are suitable for all powertrain testing: Gears, transmissions (including manual, automatic and dual clutch transmission designs), axles and transfer cases, combustion engines, electric motors and tape roller bearings. Testing is performed at end-of-line test benches under driving conditions. To correlate test data to the vehicle, in-vehicle testing is conducted in a completed vehicle using DISCOM Mobile, specifically designed for this purpose.

-

DISCOM

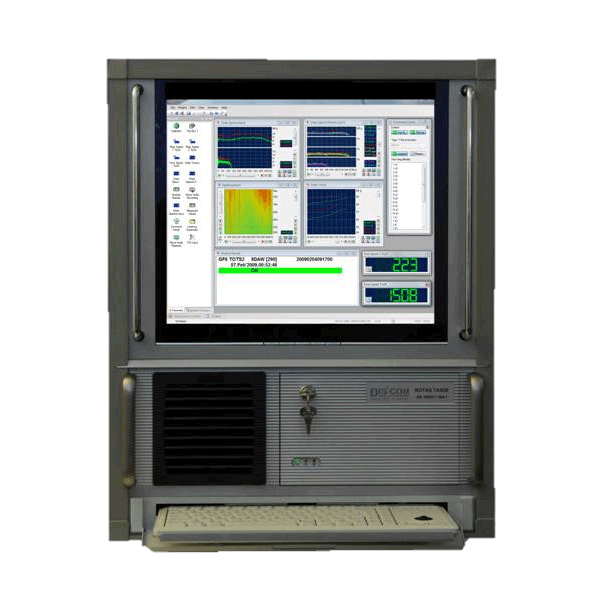

DISCOM Noise Analysis for transmissions, gearboxes, axles, electric motors and e-drives

Acoustic quality, end-of-line test system for transmissions – including manual, automatic and dual dry-clutch transmission (DCT) designs – gearboxes, axles, electric motors and e-drives.

-

DISCOM

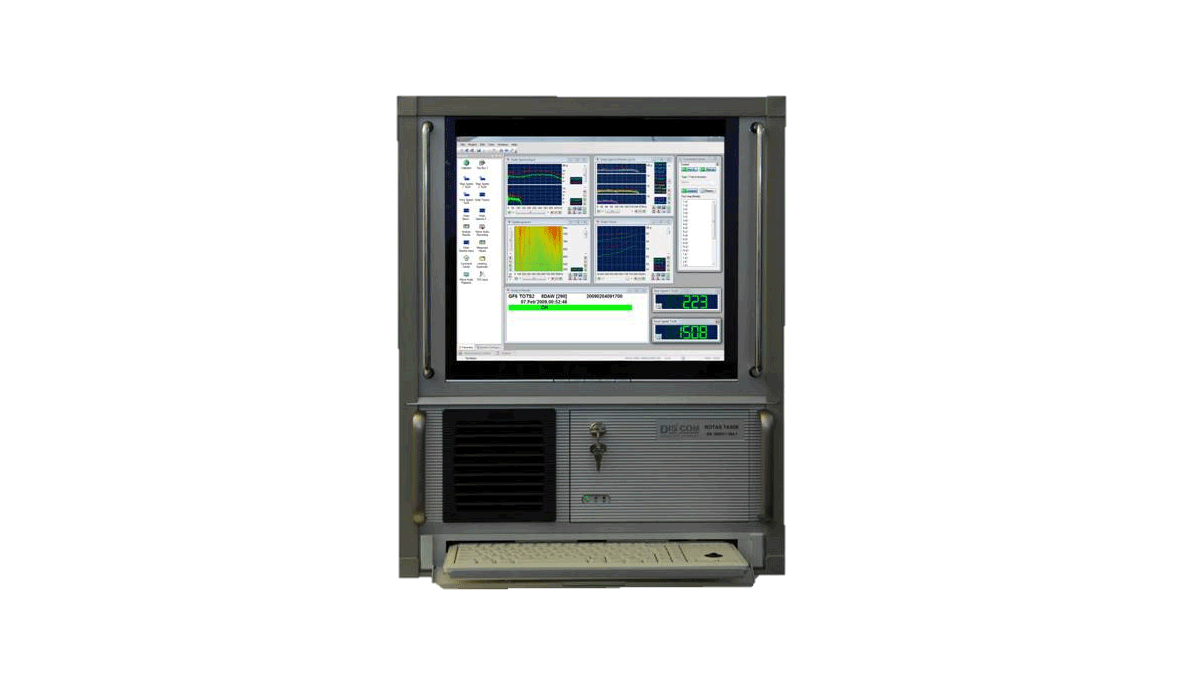

DISCOM Noise Analysis for Gear Test

DISCOM Noise Analysis for Gear Test is a complete acoustic quality, end-of-line test system for gears. The system includes transducers, data acquisition hardware, and analysis and database software.

-

DISCOM

DISCOM Noise Analysis for Engine Test

Acoustic quality, end-of-line quality assurance test system for engines that comprises transducers, data acquisition hardware, and analysis and database software.

-

DISCOM

DISCOM Mobile is an in-cabin acoustic quality system for the correlation of completed vehicle and test-stand data. The system includes all the hardware and software needed for measurement.