Hydrophones / Underwater Microphones

Brüel & Kjær hydrophones are individually calibrated, waterborne‐sound transducers. The instruments deliver a flat frequency response and are omnidirectional over a wide frequency range. All hydrophones are built with a shielded-element construction; completely waterproof, corrosion-resistant, and are able to withstand high levels of salinity. The instruments provide unrivaled depth, range, and precision when measuring sound in the lab and in ocean research.

Hydrophone Specifications-

TYPE 8105

Spherical hydrophone with rugged construction capable of withstanding pressures of up to 9.8 MPa (100 atm; 1000 m (3250 ft) ocean depth) and featuring exceptional directional characteristics.

-

TYPE 8106

Low-Noise Hydrophone with Preamplifier

Hydrophone Type 8106 features a built-in, thick-film, and low noise, 10 dB preamplifier, delivering signal conditioning for transmission over very long distances. This makes Hydrophone Type 8106 suitable for underwater sound measurements down to 1000 meters depth.

-

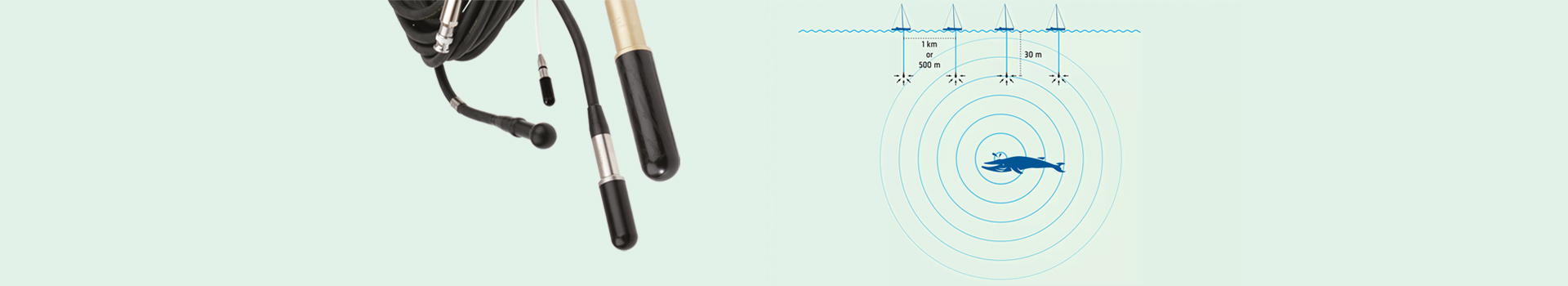

TYPE 8103

Miniature Hydrophone Type 8103 is a small piezoelectric transducer designed for high-frequency laboratory and industrial use. The instrument is particularly useful in the acoustic study of marine animals or for cavitation measurement.

-

TYPE 8104

Calibration Standard Hydrophone

A wide-range general purpose hydrophone that can also be used as a sound transmitter, making it ideal for calibration purpose. The hydrophone is supplied with 10 m waterblocked low-noise shielded cable to MIL-C-915 with BNC plug.

HYDROPHONE SPECIFICATIONS

Brüel & Kjær hydrophones are piezoelectric transducers, designed to be used underwater for recording or listening to underwater sound.

The ceramic piezoelectric sensing element and its internal supporting structure are permanently bonded into sound-transparent, lead-free, nitrile butadiene rubber. Support structures are made from metal alloys that are extremely resistant to corrosion in virtually all hostile environments and have very good anti-fouling properties when immersed in seawater.

The internal support is mechanically and electrically isolated from the metal housing, being coupled only by synthetic rubber. This provides vibration isolation of the sensing element.

RECEIVING SENSITIVITY

Each Brüel & Kjær hydrophone is submitted to an extensive aging and temperature stabilizing procedure before being individually calibrated. Individual calibration data and frequency response curves are supplied with each hydrophone.

The receiving sensitivity calibration of the hydrophones is traceable to international standards.

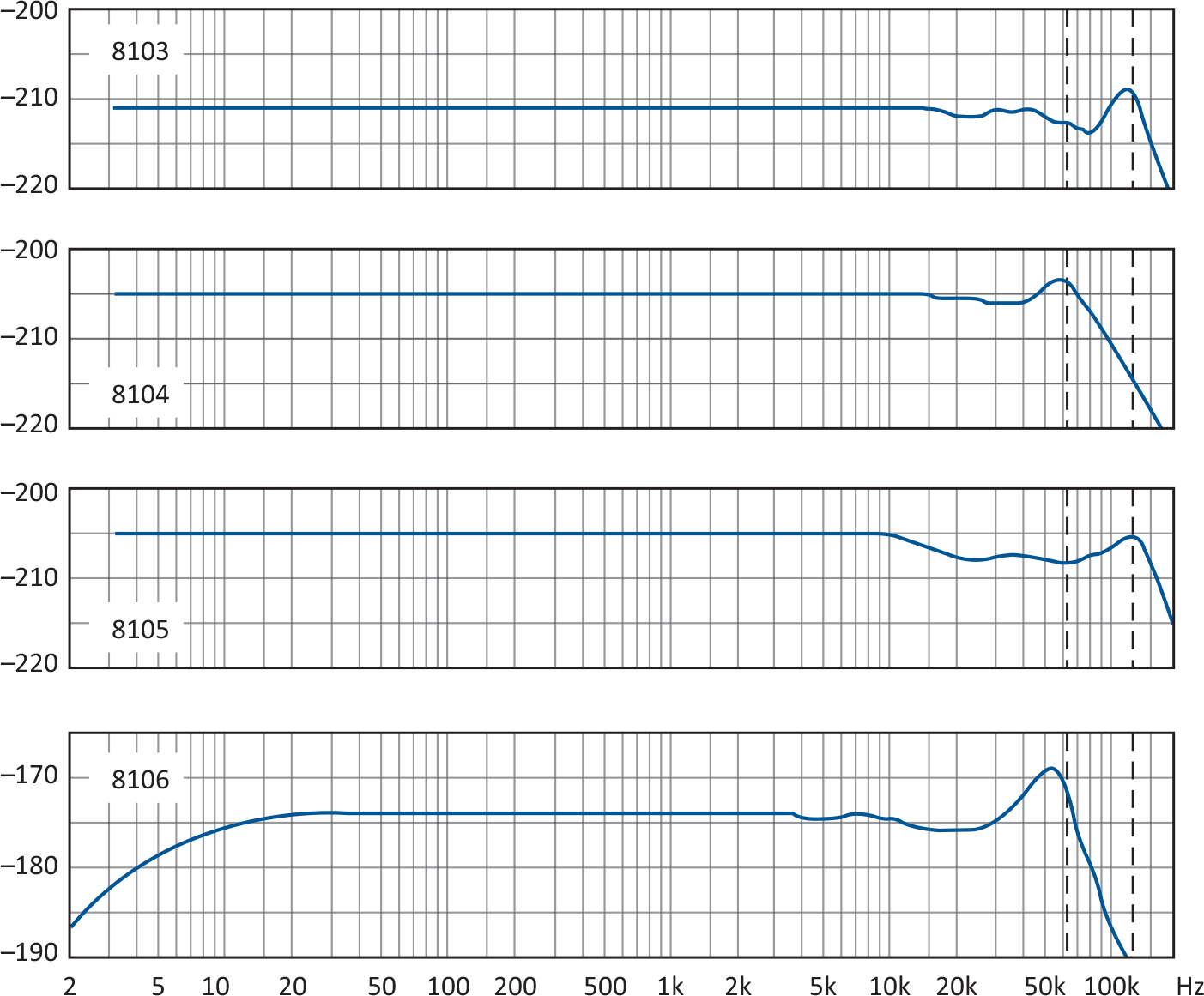

FREQUENCY RESPONSE

The frequency response of the four hydrophone types is shown here:

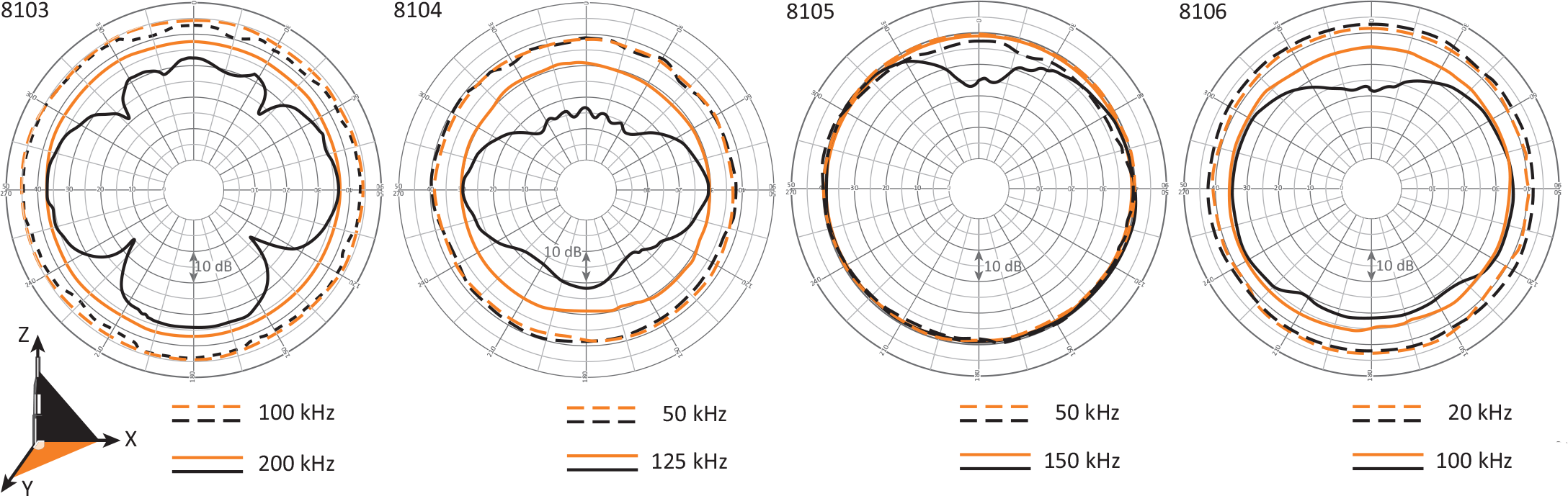

POLAR DIRECTIVITY

B&K Hydrophones deliver great omnidirectional sound measurements. The individual hydrophone directivity patterns in water, are shown here:

The polar directivity patterns were measured in free-field conditions achieved using gating techniques in a water tank. This requires a standard hydrophone as a projector and the unknown hydrophone as the receiver.

HYDROPHONE COMPARISON

|

|

Type 8103 |

Type 8104 |

Type 8105 |

Type 8106 |

|

Sensitivity* |

-211 dB re 1 V/μPa +/- 2dB |

-205 dB re 1 V/μPa +/- 3 dB |

-205 dB re 1 V/μPa +/- 2 dB |

-173 dB re 1 V/μPa +/- 3 dB |

|

Nominal Voltage Sensitivity |

29 μV/Pa |

56 μV/Pa |

2.24 mV/Pa |

|

|

Nominal Charge Sensitivity* |

0.1 pC/Pa |

0.44 pC/Pa |

0.41 pC/Pa |

N/A |

|

Capacitance* (incl. standard cable) |

3700 pF |

7800 pF |

7250 pF |

N/A |

|

Frequency Response* (re 250 Hz) Continuous is valid with integral cable |

0.1 Hz to 20 kHz +1/–1.5 dB |

0.1 Hz to 10 kHz +/-1.5 dB |

0.1 Hz to 100 kHz +1/-6.5 dB |

10 Hz to 10 kHz +0.5/-3.0 dB |

|

Length up to: |

0.1 Hz to 100 kHz +1.5/-6.0 dB |

0.1 Hz to 80 kHz +/-4.0 dB |

0.1 Hz to 160 kHz +3.5/-10.0 dB |

7 Hz to 30 kHz +0.5/-6.0 dB |

|

|

0.1 Hz to 180 kHz +3.5/-12.5 dB |

0.1 Hz to 120 kHz +4/-12.0 dB |

|

3 Hz to 80 kHz +6/-10.0 dB |

|

Horizontal Directivity † (Radial, XY Plane) |

+/- 2 dB at 100 kHz |

+/- 2 dB at 20 kHz |

||

|

Vertical Directivity (axial, xz plane): |

+/-4 dB at 100 kHz |

+/-2 dB at 50 kHz |

+/-2 dB over 270° at 80 kHz +/-2.5 dB at 100 kHz |

+/-3 dB at 20 kHz |

|

Leakage Resistance* (at 20 °C) |

>2500 MΩ |

|

||

|

Operating Temperature Range: |

-30 to +120 °C |

-10 to +60 °C |

||

|

Sensitivity Change with temperature: |

0 to +0.03 dB/°C 0 to -0.03 dB/°C |

0 to +0.03 dB/°C 0 to -0.04 dB/ °C |

0 to +0.03 dB/°C 0 to -0.03 dB/°C |

– 0 to +0.01 dB/°C |

|

Max. Operating Static Pressure: |

252 dB |

|

||

|

Sensitivity Change (Static Pressure): |

0 to –3 × 10–7 dB/Pa |

0 to 1 × 10–7 dB/Pa 0 to 0.01 dB/atm |