Machine diagnostics

Moving parts in any rotating machine will eventually cause annoying vibrations that ultimately lead to breakdowns due to production and assembly tolerances, wear, and load variation.

Ask an ExpertBy using various diagnostic techniques that use vibration measurement as an indicator, the root cause of the deteriorating machine condition can be established and corrective measures planned. Diagnostic techniques are extremely effective because they directly use the information contained in the machine vibration signature.

The signature is obtained by frequency and time analysis of the machine vibration signal from a sensor fixed on the surface of or inside the machine. It enables troubleshooting of rotor dynamic problems, rotating component deterioration and structural problems.

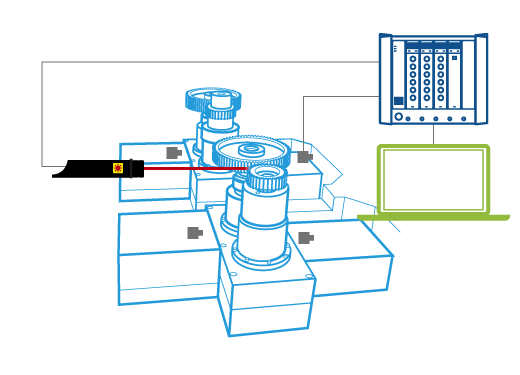

System suggestion

PULSE machine diagnostics used in run-up/down sessions can diagnose multiple faults. All analyses can be performed simultaneously and the raw signals recorded for subsequent analysis using PULSE Time Data Recorder. Diagnostics on transients is then performed with PULSE Time Capture. Results are shown in relation to data tagged with auxiliary parameters like temperature, oil pressure, position and wind speed.

The system comprises Order Analysis Type 7702-N with multi-tachometer, FFT order analysis, order tracking, signal enhancement, envelope analysis on bearings, cepstrum analysis on gearboxes and process data/auxiliary parameter logging. Any LAN-XI data acquisition module is suitable, giving up to 12 input channels. Auxiliary parameter logging requires LAN-XI module Type 3056.

Porta il suono e la vibrazione a nuovi livelli. Crea subito il tuo account per il nostro Knowledge Center!