Type 1056

DC Static Centering Unit

Designed to work as part of a system with our modal exciters and matching amplifiers, this unit enhances operation by correcting the position of the exciter’s armature or by applying pre-tensioning force to tension- or piano-wire stingers.

Request PriceCompatible with the entire range of Brüel & Kjær modal exciters, this unit serves two different purposes depending on which exciter is connected.

When paired with Type 4827 or 4828, the unit provides variable stiffness to the armature suspension and correctly centres the armature in relation to both the exciter’s housing and to the device under test (DUT) in order to ensure it is in the zero position.

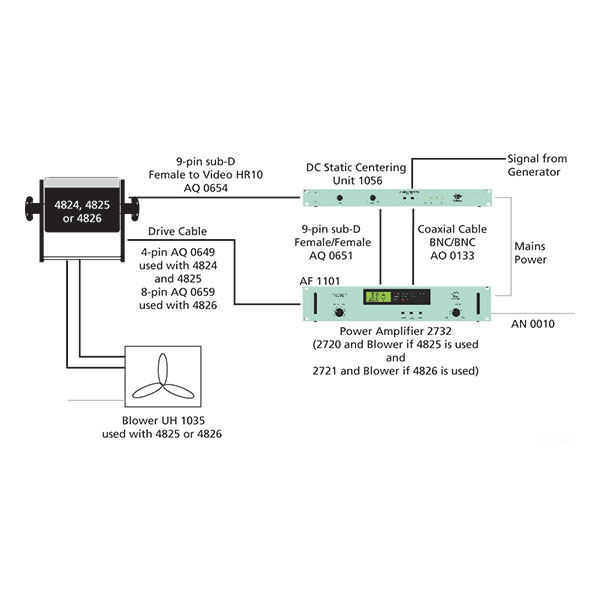

Alternatively, when paired with Type 4824, 4825 or 4826, the unit applies electrical pre-tensioning force to the tension-wire stinger linking the exciter and the input transducer attached to the DUT.

Pre-tensioning forces of up to up to 20% of the exciter’s force rating can be applied to the stinger.

USE SCENARIOS

- Armature stiffness and centring, when used with Type 4827 or 4828 (required)

- Electrical pre-tensioning, when used with Type 4824, 4825 or 4826 (optional)

CHARACTERISTICS

DC Static Centering Unit Type 1056 features a potentiometer that provides continuous adjustment of the armature position relative to the stroke or maximum peak-to-peak displacement.

The unit detects the exact position of the armature using signals

sent from an optical sensor built into our modal exciters. The sensor monitors the exact position of the armature by scanning the surface of a specially designed arm that extends from the exciter’s armature to ensure that it is at zero position (± 3 mm).

An LED display on the front panel shows the armature position and alerts you when there is over-travel – if the armature is either above or below the zero position. Another potentiometer allows stiffness of the armature suspension to be preset electronically.