There are good reasons the testing business is booming in the UK. In the export-led markets of aerospace and defence, test houses like TRaC Global offer a great deal of value: a one-stop shop where manufacturers can achieve standards compliance for many different countries. But aside from final certification, much of TRaC’s recent growth comes from helping manufacturers to navigate the whole journey to compliance, bringing the design and durability of their products up to the exacting specifications of end-users.

Hardware in the pipeline

Market demands are pushing customers into TRaC’s safe hands. In the UK aerospace sector, numerous Airbus programmes are undergoing efficiency upgrades, while new aircraft from other manufacturers like Mitsubishi Heavy Industries and Bombardier are on their way.

Nowadays more new parts and revisions to original designs must be rigorously tested to the demanding Radio Technical Commission for Aeronautics (RTCA) standard than ever before. And whenever retrofitted components must be adopted on aircraft, they need certifying before rigid flight safety deadlines. For sub-suppliers, tighter deadlines mean OEMs are less forgiving of errors or delays, and pass down to them the associated costs and liabilities – which can be millions of pounds.

Squeezing out efficiency

But not all the pressure comes from regulators. Quality demands from the end-users of defence and aerospace equipment have become more exacting. Meanwhile, supply chain efficiency programmes like the UK’s SC21 are forcing more suppliers to fulfill design requirements ‘right the first time’. In the defence industry, the UK’s Future Force 2020 programme means that all military equipment must meet tighter specifications than just the hot, dry and remote conditions for which they were procured.

For TRaC, these factors have led to test enquiries doubling over the last five years. With more quality rejections, suppliers have needed quick help to pass tests. As TRaC’s CEO Mark Heaven says, “We might get called in when a product has failed in-house testing. Or when a supplier realises they don’t have the understanding of the applied environment required. Or if testing has taken place at another external facility with little support to then fix the failures they have found. So our consultancy services are essential.”

Certification test demands

Test specifications come from legislation or customers themselves – either self-

developed or the result of contractual demands imposed on them. “Once they come to TRaC, we begin with product classification, which determines the route through the compliance and submission process, taking into account which country the product will be marketed in,” says Mark. Everywhere the story is similar though: to achieve better quality, suppliers must test to tighter tolerances, which requires more from the testing regime. “Overall, the trend is that vibration test levels are increasing, with larger forces and wider frequency ranges,” says Mark.

Windmilling engines

As standards cover more components, vibration testing for large objects has increased. At the low frequencies, ‘windmilling’ tests simulate the effect of a jet engine losing a blade – normally due to impact damage. With an unbalanced engine, significant low-frequency vibration surges throughout the aircraft. “The majority of components we test for Airbus have windmilling requirements, from interior doors to flap actuation systems,” says Mark.

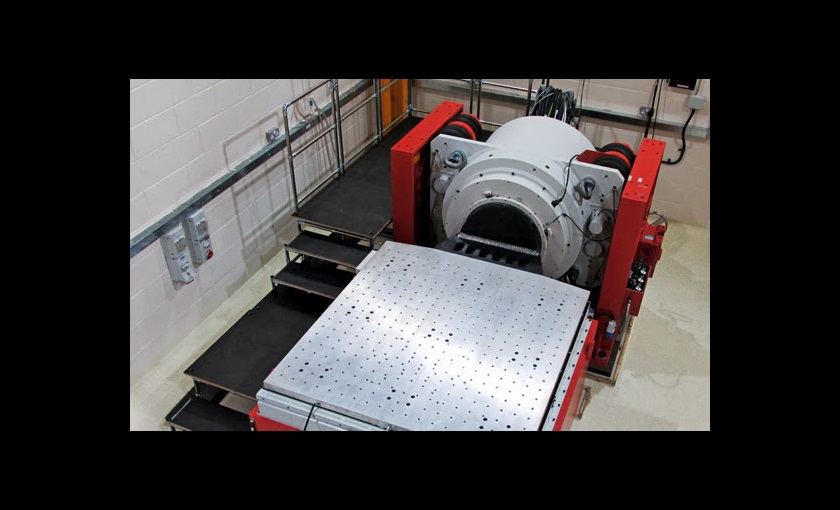

At the most demanding end of the testing spectrum, frequency, force and acceleration levels dictated by RTCA are intense. TRaC’s large shakers test objects weighing up to 4 tonnes that will experience severe vibration levels, like bridge-laying equipment. “We have three of the four (160kN thrust) LDS V984 shakers available at independent test houses in the UK,” says Mark, “so we specialize in large and challenging tests that other laboratories are unable to handle.”

Still, TRaC’s large systems are being pushed to the limit, at close to 100% operational time. With such a high demand, they need a broad range of vibration systems – nine in all. “We do over 500 vibration tests per year, so the flexibility of the range keeps lead times down, by keeping the big shakers free for the tests only they can do. And selecting appropriate shakers keeps costs down for our customers,” says Mark.

Guidance through the minefield

Keeping testing costs down is a key to TRaC’s value. For large OEMs and suppliers alike, TRaC guarantees safe and timely navigation through the many approval procedures. “Regulatory compliance for global markets is without doubt complicated and increasing, so achieving certification can be a complex and daunting task,” says Mark.

Testing incorrectly or to the wrong specifications could leave manufacturers open to in-service product failure like military vehicles breaking down while in use, resulting in danger to troops, and expensive recalls and warranty claims. So an essential aspect of running a successful test house is knowing, selecting and applying the most relevant standards and regulations, and future-proofing product compliance.

Outsourcing trust

Considering timescales is an important theme for TRaC, whose expertise is steadily entering earlier in the development process. This is initially as a development tool to make bespoke tests on prototypes for customers, and finally to prove robustness in the final design. “It is significant because it means more suppliers and OEMs are outsourcing more development testing to us, rather than maintaining expensive laboratories and engineers that are seldom used,” says Mark.

With blue-chip companies relying more on the robustness of their hardware, TRaC depends on reliability. Understanding its systems’ capabilities, and maximizing uptime are critical. Planned, regular servicing of its vibration test systems and a stockpile of genuine spare parts minimize any downtime for the customers depending on them.

“Overall, the trend is that vibration test levels are increasing, with larger forces and wider frequency ranges.” Mark Heaven, CEO of TRaC

The earlier the better

But uptime is also critical because the ‘On Time, Right First Time’ philosophy of modern aerospace OEMs means that suppliers need help fast if something

fails qualification. Such occurrences are frequent. Customers come for qualification and discover they need development testing, so a two-week programme extends into months of redesigning, remanufacturing and retesting. TRaC can add value through earlier involvement with the customer, encouraging them to invest more of their budget up front in development testing.

“Many of our customers tend to use our finite element analysis team after a product has already failed testing,” says Mark. “But with our expertise engaged earlier, we can help them steer products away from compliance pitfalls and achieve first-time success. Experience proves that testing earlier is better, when the cost of change is lower. So it’s a trend we want to continue.”

RTCA

Global (US) aerospace test procedure standard.

SC21

UK supply chain efficiency programme that encourages continuous improvement to increase yield.

TRaC Global

TRaC Global has been testing for over 65 years. Its six UK sites help 2500 organizations per year with electromagnetic compatibility (EMC), safety, environmental, telecoms and radio testing, and secures certification and approvals for 140 national markets.