Units of measurement are among the earliest tools invented by humans – and they have become more important than ever. All over the world, we make an almost infinite number of measurements every day. They play a very important role in our day-to-day lives in trade, industry, and science. Measurement standards ensure reliable and consistent data – building confidence and trust.

Measurements guarantee quality

We all use standards and units of measure in daily life – just think of shop weighing scales, petrol pumps, thermometers, and speedometers. Liters, gallons, grams, ounces, watts, volts, meters, and yards – we use an elaborate system of standard measures without even thinking about it.

The science of measurement – metrology – and its practical application is a key part of societal infrastructure today and plays a vital role in our lives. In our high-tech world, proper measuring is of fundamental importance.

Economists have estimated that the spending on measurements in the industry adds up to around 1% of GDP in the European Union, while the total benefits are 2.7% of GDP. Similar figures apply to the US.

Calibration ensures confidence

The industrial need for comparable, accurate, and precise measurements has led to standardization, and as a result, a growing need for calibration.

Calibration is a fundamental step in the practice of measurement. It is the process of determining the relationship between the values indicated by a measuring instrument or system and the corresponding units of a defined system of measurement.

In practice, the simplest calibration is a comparison between measurements – one made with the instrument under test and another measurement with known uncertainty made in a similar way with a second instrument, the reference unit.

We can trace the measurement of the reference unit back to international standards through a chain of measurements with known uncertainties. This traceability is a fundamental principle in any type of calibration work.

Quality is key

As components of our instruments age and undergo changes due to environmental or mechanical stress, performance gradually degrades, or drifts. When drift happens, test results become unreliable, and quality suffers. We cannot eliminate drift, but we can detect and contain it through the process of calibration.

The economic success of most manufacturing industries depends on the quality of their products, a requirement in which measurement and the adequate functioning of measurement instruments play a key role. Likewise, measurement is important in innovation as it can certify that a new product is better than existing ones.

Regardless of what products we manufacture, we need absolute confidence in the integrity of our measurement instrumentation. Neglecting calibration can lead to production or machine downtime, process quality issues, cost over-runs, or even product recalls.

Industrial metrology ensures quality in industrial activities – national and international trade increasingly requires demonstrated conformity to standards and specifications and mutual recognition of measurements and tests. For developing countries and countries in transition, metrology and calibration is a way to establish the trust in products and services that are needed to hook up to the global business.

Ghana

Raising the standard: Calibration to boost industry

In Ghana, the Council for Scientific and Industrial Research (CSIR) has acquired Brüel & Kjær calibration systems. The acquisition is part of an initiative funded by the European Union (EU) to boost business development in Ghana.Ghana, located in West Africa, has witnessed annual economic growth averaging over 6.4% since 2000, which is largely driven by expanding service and industrial sectors. The start of oil production in 2010 has the potential of transforming the economy.

The President of Ghana Academy of Arts and Sciences, Professor Francis Allotey, states, “Modern science, technology and innovation enterprise is expensive but a necessary investment for the future”.

The Government of Ghana’s agenda is to use science, technology, and innovation as the driving forces towards the economic development of the nation, but according to CSIR, Ghana’s scientific institutions are struggling with challenges such as obsolete scientific equipment and inadequate training.

In 2011, the EU and the Republic of Ghana initiated a trade-related assistance program. Among others, the program focuses on the basic step of implementing the national quality policy covering areas such as metrology, accreditation, standardization, conformity, certification, and regulation.

The acquired calibration systems will function within the Institute of Industrial Research (CSIR-IIR), a leading institute of CSIR. The mission is to drive national development and global competitiveness in the industry through research into the process and product development, and promotion of scientific instrumentation and calibration.

The central quality control services will soon be in place and the hard work to establish a market for calibration in relatively new, export-oriented industries can begin.

Macedonia

The acoustics laboratory supports market integration

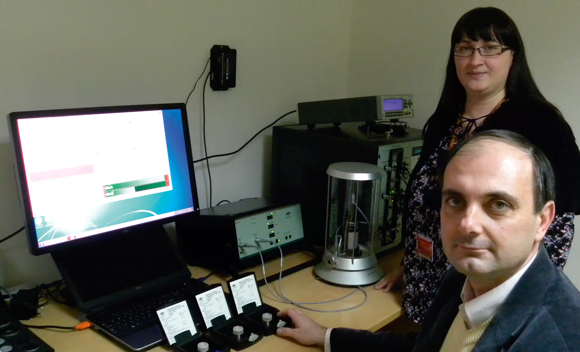

In 2014, the National Bureau of Metrology (BoM), in the Former Yugoslav Republic of Macedonia acquired Brüel & Kjær calibration systems to establish a national acoustics laboratory. The Republic of Macedonia, located in south-eastern Europe and with a population of just above two million, is applying for membership of the European Union (EU).

In 2011 – 2012, the Macedonian government and EU implemented a joint project to build up the capacities of BoM in relation to scientific and industrial metrology and to harmonize Macedonia’s relevant legislation with that of the EU.

The Economy Minister of the Republic of Macedonia, Valon Saraqini, has stressed that the project contributes to the free movement of goods, “Its implementation lays out a structure for quality and a developed metrology system, meaning that all technical barriers for functioning trade have been lifted”.

The break up of Yugoslavia in 1991 led to the dissolution of the federal metrology infrastructure. As a result, all republics had to establish their own standardization and metrology institutions. In 2002, the Macedonian government adopted a Law on Metrology adequately harmonized with EU requirements. In 2004, BoM started its operational activities and began to set up a system of accredited calibration laboratories.

“Our economic benefit will be visible,” says the Technical Manager of the BoM acoustical laboratory, Mrs. Stanislava Kroneva Petrovska. “We have widened our scope of services, and domestic customers benefit from having shorter procedures and lower costs”.

The acoustical laboratory is now on a higher level and BoM can take part in scientific projects regarding acoustical metrology. The metrological infrastructure can be internationally recognized and with further accreditation, BoM will be able to provide traceability to other laboratories in the region’s other countries.

Inscreva-se em nossa Newsletter e receba as últimas histórias do nosso mundo de ruído e vibração