Vehicle Testing and NVH Program support

Projects include initial subjective and objective benchmarking, vehicle-level and system/component-level target setting, NVH troubleshooting and development to achieve programme targets, and launch support.

Ensuring the acoustic and vibration performance of a vehicle is hugely challenging and requires expertise in a range of noise vibration harshness (NVH) performance domains. To achieve fast and efficient response, automotive OEMs sometimes choose to outsource the responsibility for NVH vehicle integration.

We have worked with a number of customers where we have taken full responsibility for development of all aspects of noise and vibration in the vehicle programme and have acted as the noise and vibration lab.

Activities range from initial subjective and objective benchmarking, vehicle-level and system/component-level target setting, NVH troubleshooting and development to achieve programme targets and launch support.

Activities include:

- Benchmarking activities to aid in vehicle-level target setting, along with cascading of targets down to the system and component-level.

- Power train NVH responsibilities (acoustic and structural development, mount development, rigid-body modes, modal coupling, intake/exhaust assessments, etc.)

- Road noise development (structural/acoustic troubleshooting and countermeasure development)

- Wind noise development (noise source identification, leak path studies, acoustic package optimization, and countermeasure development)

- Acoustic package optimization to achieve programme targets, utilizing both conventional methods as well as advanced acoustic imaging techniques to streamline evaluation time

- Body structure dynamic-mode assessments against programme targets to aid troubleshooting efforts and identify potential concern areas for power train noise, road noise, etc.

- Support through to launch, including key driving evaluations by management and press events

Here are some projects and project elements we have worked on with customers:

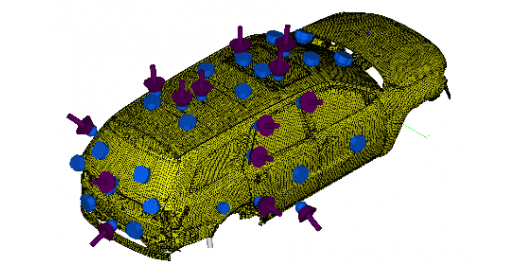

A software and services company working with an automotive OEM requested that we assess (experimentally) all the cabin acoustic cavity modes in a vehicle, up to 150 Hz, to achieve better correlation between test and Computer-aided engineering (CAE) analysis.

Stationary acoustic and vibration measurements were conducted in a hemi-anechoic chamber. Vehicle body panels were instrumented with accelerometers and several microphones were positioned in the cabin. For the acoustic artificial excitation tests, a low-frequency volume velocity source was placed behind the rear seats. For the structural artificial excitation tests, a rear wheel was removed and a shaker positioned to excite at a rear suspension attachment point. Measurements were made at customer-defined locations with different trim configurations, from fully trimmed to completely bare. Complete datasets of acoustic, structural and vibro-acoustic transfer functions (V/F, P/F, V/Q, P/Q) were taken for each trim configurations and provided to the CAE team for correlation.

Suscríbase a nuestro boletín informativo y recibirá las últimas noticias de B&K sobre sonido y vibración