Sound and Vibration Measurement Method development

Engineering services for development of procedures and methods, jury evaluation, integration of test and CAE data, test bench development and training

Efficient and effective test procedures for developing and optimizing the sound and vibration performance of a product has great impact on both the quality of the final product and the speed with which products get to market. This includes ensuring that the right tools, procedures and methods are applied to problems and that procedures are not unnecessarily complicated. Most importantly, the engineers and technicians doing the testing need to have the right skills to conduct the work.

We have worked with a number of customers on projects such as the development of simplified procedures to estimate contributions for noise and vibration, integration of test and CAE data to help improve the efficiency of the product development process, method development using jury evaluation and development of customized test benches for NVH testing. At project delivery, we always ensure that the customer is properly trained to continue the work independently.

Here are some projects we have worked on with customers to optimize their processes, methods and tools:

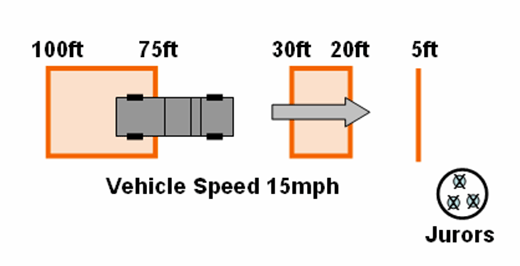

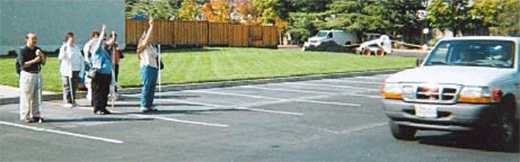

The blind community is concerned that vehicles are becoming too quiet and unsafe for sight-impaired pedestrians. To evaluate alternative test procedures for assessing the detectability of quiet vehicles by the blind community, we conducted a study in conjunction with the University of California, Davis. We performed a jury study at the National Federation of the Blind of California Conference, where blind volunteers from the conference participated. A combustion engine vehicle was converted into an electric vehicle and speakers were attached at each corner.

The vehicle was driven past the volunteers three times under different conditions. The subject raised their hand when they heard the vehicle and the distances from the subject were noted. The results of this study indicate that the loss of normal combustion engine noises may significantly affect the ability of blind individuals to distinguish approaching vehicles and that a substitute sound generation mechanism may be required to reverse this risk.

> Investigation into the detection of a quiet vehicle by the blind community (conference paper)

An Asian commercial vehicle OEM needed to design an optimized acoustic treatment package for a commercial truck.

They approached us to get training in NVH testing methods and statistical energy analysis (SEA) modeling strategies. Working in cooperation with a CAE partner, we developed and implemented a test plan to decompose total noise inside the truck cabin into structure-borne and airborne contributions and developed cost and performance-optimized interior acoustic treatments.

> SEA Modeling and Validation of a Truck Cab for Sound Package Optimization (Conference paper)

> Optimization of the Sound Package of a Truck using Statistical Energy Analysis (Conference paper)

A North American automotive OEM wanted to develop an acoustic transmission loss (TL) test bench that would allow test of an entire exhaust system down to 20 Hz.

Using an Impedance Tube Type 4206 as a starting point, we designed and fabricated a very low frequency sound source with higher sound pressure level output to allow for testing of the entire exhaust system with good frequency response down to 20 Hz.. In addition, we developed and fabricated components required to connect the exhaust system to the standard 100 mm and 29 mm diameters of the Impedance Tube. We also made a pair of termination elements of sufficiently varied impedances to facilitate testing using the so-called 2-load termination method. As a part of the development process, the test system was validated using a simple expansion muffler as a test object. At the conclusion of testing the OEM was trained to operate the test stand, and is now able to perform TL measurements independently.

An automotive OEM requested development of a pass-by-noise decomposition and synthesis tool. Test and analysis methods were developed to estimate the vehicle-level pass-by performance from component level data, both from physical and/or analytical sources. The methods allow for the estimation of the overall vehicle-level pass-by noise along with the contributions to the total and dominant frequency content from each of the key noise sources. This information can be used in two distinctly different ways. First, the pass-by noise levels can be estimated for new component-level design alternatives, from either physical testing and/or analytical predictions. Second, a target pass-by noise level can be specified and the required acoustic performance for the dominant noise sources can be calculated.

> Vehicle Pass-by Noise Estimations for Component-Level Design (Conference paper)

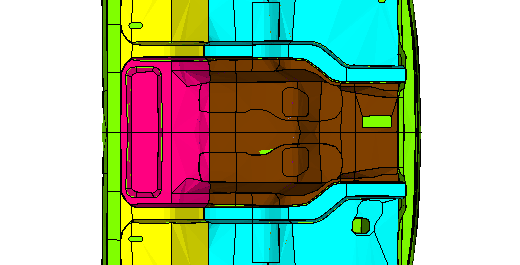

An automotive OEM needed to optimize the acoustic package of its production truck and remove redundant stopgap fixes that had been applied pre- and post- launch to achieve the desired NVH performance.

- to optimize the released NVH package for improved cost and weight without degradation of NVH performance

- to develop a practical, efficient, and reliable process to optimize NVH package development through integration of test and analytical tools.

The goals were achieved by developing a synthesis process that allowed for the prediction of interior sound levels for alternative NVH package configurations. Acoustic contributions from the powertrain through specific paths into the interior of the cab were synthesized with and without modifications, making it possible to listen to different acoustic package scenarios and compute sound quality metrics, to identify the most cost-effective configuration.

> SEA Modeling and Validation of a Truck Cab for Sound Package Optimization (Conference paper)

> Optimization of the Sound Package of a Truck using Statistical Energy Analysis (Conference paper)

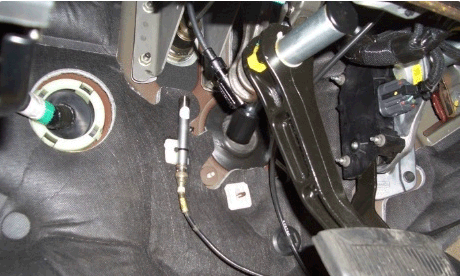

A vehicle OEM wanted to evaluate the sound quality (SQ) effect of an alternate powertrain in a production vehicle without having to actually swap the powertrain. We developed a new process that leveraged an experimental time-domain Source Path Contribution (SPC) model of the existing vehicle and powertrain. This allowed us to virtually swapping powertrains. Different engines could be virtually implemented into the SPC model and the results listened to and compared to established platform targets. The main objective of the project was to develop a test and data analysis process completely open to the OEM’s engineers to replace a supplier’s proprietary, frequency-based, method. The new process can be used to pre-empt severe sound quality concerns when integrating different/new powertrains into production vehicles. The project demonstrated that the SPC reconstruction of interior noise at steady state and run-ups in the tested vehicle with the ‘virtually’ swapped powertrain correlated well with measured data and therefore could be trusted to assess the SQ impact of a different powertrain in the same body.

Reference paper

Suscríbase a nuestro boletín informativo y recibirá las últimas noticias de B&K sobre sonido y vibración