Measurement Troubleshooting and analysis

Troubleshooting of specific sound and vibration problems and root cause analysis of sound and vibration issues. Identification and implementation of countermeasures to mitigate the problems.

Reduction of noise and vibration in products helps both to optimize the user’s experience of the product and to ensure that the product will operate to specification during its expected lifetime. This is the case in the development of new products, evaluation of product changes, and in investigating issues in existing products. Strategies include troubleshooting of specific sound and vibration problems and root cause analysis of sound and vibration issues. A central activity in this process is identifying and implementing countermeasures to mitigate the problems.

We have worked with a number of customers on projects such as noise reduction in operating products and identification of noise and vibration root causes at design change. Product durability can also be addressed using troubleshooting and root cause analysis methods.

Here are some projects we have worked on with customers to troubleshoot sound and vibration problems and recommend remedial actions:

In order to effectively control noise levels at the operator position in a vehicle, it is important to have a good understanding of what elements of the vehicle contribute to the operator position levels. We performed source path contribution (SPC) analysis on a skid steer loader to help understand the dominant contributors to the operator position sound pressure levels. The SPC analysis requires acoustic (P/F) and vibration (A/F) transfer functions from the source locations to the receiver location in addition to operational source characterization (radiated acoustic and vibration) measurements, so that the contribution from each source and path may be calculated.

We augmented this analysis with what-if studies, in which the data was analyzed to show what reductions in source strength would be required to reduce the operator levels to a desired target level. From this testing and analysis, the vehicle manufacturer was able to gain a better understanding of how best to control the noise at the operator position. They also got an insight into and understanding of the SPC process and capabilities.

> BOBCAT reduces operation vibrations with whole-vehicle analysis (Case study)

A medical devices company needed assistance in evaluating the NVH performance of a wound therapy device and identifying best guidelines for reducing noise and vibration. Operational noise and vibration measurements were conducted within a full-anechoic chamber. We used the source-path-receiver approach, concentrating on FFT and order analysis to identify the root causes of noise and vibration introduced by the device.

From the test results, we were able to suggest effective countermeasures to reduce noise and vibration both at the source and along the path to the receiver. However, as the device was already well into development, the customer decided to implement only path-related countermeasures.

A manufacturer of agricultural, environmental, and construction equipment elected to outsource the measurement of sound power on their tub grinder. They also wanted to learn the techniques to troubleshoot their sound power issues on their own. Standardized sound power measurements were conducted and used to quantify sources with a focus on assessing which bands contributed the most to the overall level. Once focus was narrowed, both acoustical and structural resonances were calculated/measured to determine whether the root cause was a forced response or natural frequency. A root cause was identified and recommendations were accepted that significantly reduced the sound power results of the tub grinder. The customer learned the techniques used for this project so that they can solve similar issues in the future.

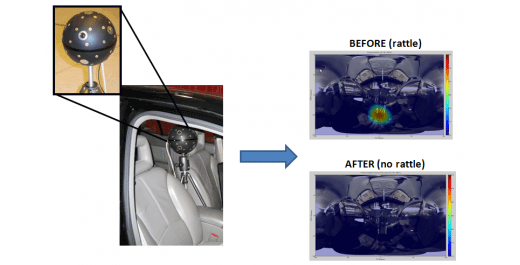

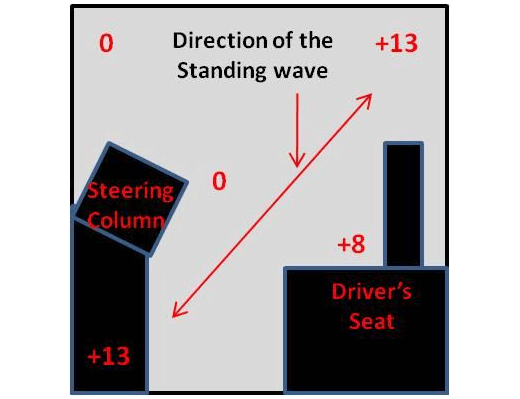

A Korean transplant needed a buzz, squeak and rattle (BSR) validation of a facelift of its production vehicle for the North American market. Areas of concern were the instrument panel, the centre console and the headliner. To conduct this test, we placed the vehicle on a 4-post shaker, with various drive files used to excite different BSR events.

To facilitate the communication with the Korean team, we used a spherical beamforming array system to take acoustic pictures of transient BSR events before and after the adjustments to the vehicle.

Wind turbines are fitted with alarms to make sure any imbalances in the system are identified and corrected before a turbine develops critical faults. A maker of custom wind turbine blades and ventilation equipment asked us to investigate an imbalance issue in a blade at a customer site in Mexico, as the imbalance alarm kept sounding. To understand the issue, we conducted operational vibration measurements on-site. We used FFT, order analysis, and balancing techniques to characterize the imbalance associated with the blades. The measurements showed that it was not imbalances in the blades setting off the alarm. An issue elsewhere in the installation was the source of the vibration issues experienced by the blade manufacturer’s customer.

A large vehicle chassis dynamometer exhibited excessive background noise in the 200 and 250 Hz band. We performed operational and artificial excitation testing and established that the noise was structure-borne and due to a bending and a torsional mode of the reaction mass of the dynamometer motor, coupled to a bending mode of the motor driveshaft. The animation of the modes at these two frequencies was confirmed from both modal testing and from operating deflection shapes extracted from operational data. Tuned mass dampers were designed and successfully installed to solve the problem.

A large vehicle chassis dynamometer exhibited excessive background noise in the 200 and 250 Hz band. We performed operational and artificial excitation testing and established that the noise was structure-borne and due to a bending and a torsional mode of the reaction mass of the dynamometer motor, coupled to a bending mode of the motor driveshaft. The animation of the modes at these two frequencies was confirmed from both modal testing and from operating deflection shapes extracted from operational data. Tuned mass dampers were designed and successfully installed to solve the problem.

We worked with a manufacturer of lawnmowers to help them understand the vibration performance of one of their products. To identify the frequency ranges of interest, we acquired artificial excitation data. We then measured during operation to understand the mower's vibration levels under normal use. Modal analysis was used to understand how best to improve vibration at the operator (receiver) location. The results were delivered to the customer for integration into future development of vibration quality in their products.

An agricultural equipment manufacturer approached us to troubleshoot an acoustic boom in a tractor and to identify possible countermeasures. We measured static and operational noise and vibration at the customer’s facility applying the source-path-receiver model. Spectral, order, and modal analysis were used to understand key components of the acoustic boom.

The boom consisted of high source levels coupled with a modal alignment issue that appeared after a design change. We recommended reducing the source level and shifting the coupled resonances. In addition to recommended changes, we also helped the customer develop a mode alignment chart to use as a reference during future tractor development processes.

Suscríbase a nuestro boletín informativo y recibirá las últimas noticias de B&K sobre sonido y vibración