Precision

microphones

since 1945

Micrófonos de medición

Los micrófonos de medición de Brüel & Kjær son instrumentos de precisión de la más alta calidad. Si bien el diseño de un micrófono puede parecer bastante simple, su producción requiere la máxima atención y control para preservar la sensibilidad y la estabilidad.

Select the Right Microphone-

Conjunto microfónico

Conjunto microfónico, formado por un micrófono de medición Brüel & Kjaer asociado al preamplificador más idóneo, todo ello integrado en una unidad lista para usar en aplicaciones de medida.

-

Cápsulas de micrófono

Las cápsulas de micrófono de Brüel & Kjaer tienen diámetros de 1 pulgada, 1/2 pulgada, 1/4 pulgada o 1/8 pulgada. Requieren un preamplificador de micrófono.

-

Preamplificadores

Los preamplificadores de micrófono se combinan con una cápsula de micrófono condensador. Proporcionan conversión de impedancia, filtrado y capacidad para utilizar grandes longitudes de cable sin degradación significativa de la señal.

-

Hidrófonos

Los hidrófonos de B&K son transductores de sonido subacuático. Se calibran individualmente, tienen una respuesta de frecuencia plana y destacan por su comportamiento excepcionalmente omnidireccional en un amplio rango de frecuencia.

-

Outdoor Microphones

Our Outdoor Microphones are specifically designed to operate under a wide range of temperatures, humidity and precipitation and are ideal for long-term environmental sound measurements.

-

Micrófonos especiales

Gama de micrófonos especiales adaptada a aplicaciones de medida específicas. Incluye micrófonos para exteriores, micrófonos para arrays y sondas de micrófono.

TABLE OF CONTENTS

1. Microphone Specifications

2. Standards

3. Dynamic Range

4. Magnetic Fields

5. Effects Of Temperature

SELECTING THE RIGHT MICROPHONE

Selecting the best microphone for a given application can seem to be an overwhelming task due to the many different types to choose from.

Firstly, condenser microphones are either externally polarized or prepolarized. They come in different sizes: 1‐inch, 1/2‐inch, 1/4‐inch, or 1/8‐inch and are optimized for either free‐, pressure‐, or diffuse‐field. Microphones that do not directly match one of these classes are denoted as "Special Microphones".

Not all positions in the matrix correspond to a type of number, for example, 1-inch microphones are normally externally polarized, since they were introduced before prepolarized microphones could be produced with sufficient stability.

1/8‐inch microphones are pressure types. Due to their small size, the free‐field and pressure response are approximately the same up to quite high frequencies (for example, the free‐field correction is less than 1 dB at 15 kHz).

Brüel & Kjær Measurement Microphones are mapped in this matrix to provide a quick overview:

| Type of Microphone | 1/8‐inch | 1/4‐inch | 1/2‐inch | 1‐inch | Polarization | |

|

Free‐field | 4954 | 4940 4176 4188 4189 4950 4966 |

Prepolarized | ||

| 4939 | 4190 4191 |

4145 | Externally polarized | |||

|

Pressure‐field |

|

4944 |

4947 4948 4949 4953 4971 |

Prepolarized | |

| 4138 | 4938 4941 |

4192 | 4144 | Externally polarized | ||

|

Diffuse‐field | 4942 | Prepolarized | |||

| 4943 | Externally polarized | |||||

| Special | 4957 4958 |

4948 4949 |

Prepolarized | |||

| 4941 | 4180 4193 4955 |

4160 4179 |

Externally polarized | |||

MICROPHONE SPECIFICATIONS

Q: Which kind of input module – classical or CCLD?

CCLD (including DeltaTron and IEPE) can only work with prepolarized types, and classical input with both prepolarized and externally polarized cartridges. For portable instruments (such as sound level meters) and where high humidity is present, prepolarized microphones are preferred. For more general use in the laboratory or where high temperature is present, the use of external polarized microphones are recommended.

More information on CCLD and Classical input is available on the microphone preamplifier page.

Q: Does the microphone have to fulfil any specific standard?

If this is the case, please review the section on microphone standards listed below.

Frequency range and maximum sound pressure level (SPL) will often determine which microphone size to use. Generally, a smaller microphone has a broader frequency range and a lower sensitivity. Please review the section on Maximum Limits and Dynamic Range below.

Q: For which sound field should the microphone be optimized?

For measurements made away from reflecting surfaces, for example, when making outdoor measurements, or in acoustically well‐damped indoor environments, a free‐field microphone is best. But for measurements made in small closed couplers, or close to hard surfaces, a pressure‐field microphone is best.

For measurements in enclosed areas where reverberation is likely, microphones optimized for diffuse‐field (random‐incidence) response are best. In some cases, pressure type microphones can also be found to have sufficiently flat random‐incidence response.

This is because the random‐incidence response of a pressure‐field microphone is much flatter across the frequency range than that of a microphone optimized for flat free‐field response.

Special Measurement Applications

A special case is the measurement of surface pressure where surface microphones would be the obvious choice. For applications that go beyond normal use-cases, a special microphone can be selected.

As an example, laboratory reference microphones, outdoor microphones, array microphones, infrasound microphones, etc.

MICROPHONE STANDARDS

Laboratory reference microphones are specified in the international standard IEC 61094–1:2000.

Measurement microphones are specified in the international standard IEC 61094–4:1995.

These standards use the abbreviation WS for working standards, for example, measurement microphones used in daily routine measurements, while the abbreviation LS denotes laboratory standards.

The digits following “WS” indicate as follows:

- 1 = 1‐inch microphone

- 2 = 1/2‐inch microphone

- 3 = 1/4‐inch microphone

The letter “F” denotes a free‐field type and “P” a pressure‐ field type.

Electroacoustic Standards

The most relevant electroacoustic standard is the IEC 61672:2002 “Electroacoustics –Sound Level Meters”.

Although the microphone is an important component in any system that has to comply with IEC 61672 there are many other factors to consider. Despite this, the table show which microphones are suitable for systems that have to fulfil the requirements of IEC 61672.

It is also worth considering other parameters such as phase response, venting, environmental exposure and documentation.

| IEC 61094 | IEC 61672 | ANSI |

| A IEC 61094 – 4 WS1F | I IEC 61672 Class 1 | K ANSI S1.4 Type 1 |

| B IEC 61094 – 4 WS2F | J IEC 61672 Class 2 | L ANSI S1.4 Type 2 |

| C IEC 61094 – 4 WS3F | M ANSI S1.12 Type M | |

| D IEC 61094 – 4 WS1P | ||

| E IEC 61094 – 4 WS2P | ||

| F IEC 61094 – 4 WS3P | ||

| G IEC 61094 –1 LS1P | ||

| H IEC 61094 –1 LS2P |

MAXIMUM LIMITS AND DYNAMIC RANGE

Inherent Noise: Even if a microphone is placed in a “totally quiet” room there will be some Brownian movement of the microphone back-plate and diaphragm. These movements correspond to very small pressure fluctuations and will cause changes in the cartridge capacity which – if a polarisation voltage is present, will cause an output voltage from the microphone.

The SPL corresponding to this output voltage is defined as the inherent noise of the cartridge.

3% Distortion Limit: Even though the condenser microphone is highly linear, at a certain pressure there will be some distortion of the output signal. At Brüel & Kjær we specify the 3% distortion limit as a recommended maximum limit for accurate measurements.

10% Distortion Limit: Increasing the sound pressure behind the 3% distortion limit will result in a further increase in distortion. In some cases, a 10% distortion limit is specified. In many practical cases, the 10% distortion limit is determined by the preamplifier.

Maximum SPL: Due to mechanical forces acting on the cartridge there is a maximum pressure level which should never be exceeded or the long-term stability can be influenced and/ or mechanical damage can happen. The corresponding sound pressure level is called the maximum SPL.

Dynamic Range of Microphone Set: In a practical application, the lower limit of dynamic range is determined by the combined noise from the cartridge and the preamplifier. The upper SPL limit will often be determined by the output voltage swing from the preamplifier. This is especially important when using CCLD (IEPE) preamplifiers, since here the maximum voltage is limited by the input stage compliance (open-circuit) voltage.

A compliance voltage of, say, 28 V as used in many DAQ front-ends, such as our LAN-XI Front-ends, will limit the maximum voltage swing to around 20 Vpp. This may determine the real maximum limit of a microphone/preamplifier set.

Brüel & Kjær defines the dynamic range as the range from the noise floor to the SPL resulting in a 3% distortion limit with a given microphone set, and nominal compliance voltage where relevant

| SPL limitations and microphone cartridge sensitivity using a CCLD preamplifier with 14 V pp output voltage swing |

||||

| Max. SPL dB | 50mV/Pa | 12.5mV/Pa | 3.16mV/Pa | 1mV/Pa |

| 138 | OK | OK | OK | OK |

| 150 | OK | OK | OK | |

| 162 | OK | OK | ||

| 172 | OK | |||

Note: With classical input and 120V supply the maximum SPL is approximately 12 dB higher

MEASURING IN MAGNETIC FIELDS

When performing sound measurements in magnetic fields like on a hybrid or electrical car, close to wind turbine generators, close to big MR scanners or other similar equipment, it may be beneficial to use the latest Brüel & Kjær microphones made out of titanium.

The titanium is much less susceptible to magnetic fields than metals normally used in microphones. The magnetic field impact is seen as noise and increases the noise floor of the microphone. For example:

- 1/4‐inch Array Microphone 4958 has a susceptibility to magnetic fields corresponding to an equivalent SPL of 40 dB for an 80 A/m, 50 Hz field

- 1/2‐inch Free‐field Microphone Type 4189 has a susceptibility to magnetic fields corresponding to an equivalent SPL of 6 dB SPL for an 80 A/m, 50 Hz field

- Titanium microphone Types 4955 and 4961 have no detectable influence from an 80 A/m, 50 Hz magnetic field

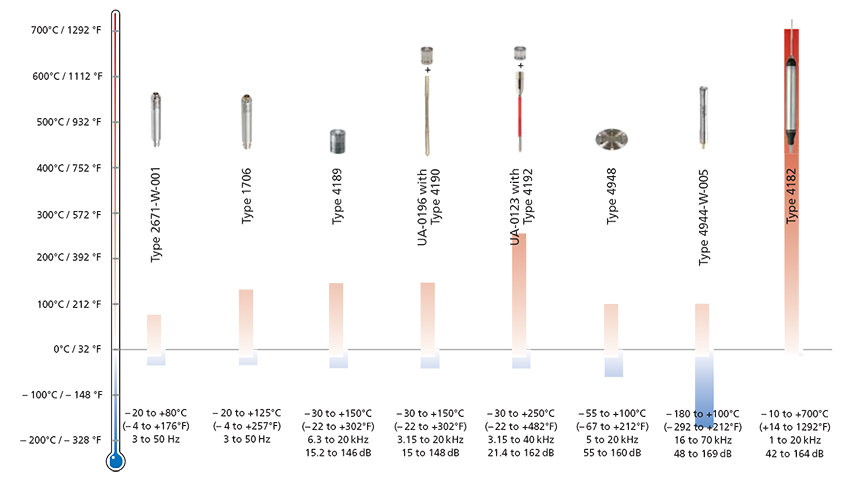

THE EFFECTS OF TEMPERATURE

As temperature and humidity are both factors which pose the greatest threat to the performance of condenser microphones, pre-production microphones are thoroughly tested for resistance to these influences, typically in temperatures from −20° to +70°C and in humidity of up to 90% at 40°C.

What happens at high temperatures (above +80 °C)?

- Electronic components may exceed their maximum junction temperature. This is very serious and should be avoided.

- Prepolarized microphones may lose electret voltage. This will result in permanent sensitivity loss, which means, externally polarized microphones should always be used if high-temperature tests are performed for longer periods of time.

- The diaphragm tension will reduce. This means increased sensitivity and changes in frequency response.

- The cable jacket and other isolators may melt. While this is not beautiful, it is not always catastrophic.

- In practically all cases, an exponential increase in the inherent electronic noise must be expected. The basic rule of thumb: Many temperature depending factors will double for every 10° temperature increase (Arrhenius' law).

Microphones specified at 23 °C have a temperature coefficient that specifies how the microphone will behave with changed temperature. This parameter tells something about the microphone’s stability and quality. Our datasheets provide temperature coefficient information.

General-purpose microphones, such as Microphone Type 4189, perform well within their specifications in the temperature range from –30 to +150 °C. General purpose preamplifiers have a relatively stable DC bias up to around 80 °C. They are specified from–20 to +60 °C (–4 to +140 °F), but work very well at temperatures of up to +80 °C, with some increase in noise.

High‐temperature Preamplifier Type 1706 is designed to perform up to 125 °C. At high temperatures, it has a more stable DC bias point and no reduction of maximum SPL limit. The electrical noise increases at high temperatures, which affects the lower limit of the dynamic range of the microphone set, combining a microphone cartridge and preamplifier, limiting its ability to measure very low sound pressure levels.

In regards to the use of microphone cables in high temperatures, PUR cables are not recommended. Instead, silicone cables are rated at 150 °C, and PFA cables provide realiable measurements from –75 to +250 °C, such as cable AO‐0406.

What if it gets really hot (+125 °C)?

- You must get the preamplifier away from the hotspot

- Flush Mounting Kits UA‐0122 and UA‐0123 or Swan Neck UA‐0196 are great for this

- Sometimes Probe Microphone Type 4182 will do the job

Type 4182 allow sound pressure measurements to be made in small or awkward places or in harsh environments with high temperatures (up to 700 °C). The probe microphone has a smooth frequency response from1 Hz to 20 kHz, with a very smooth high‐frequency roll‐off.

Measurements can be performed extremely close to the sound source due to its small size. Measurement points can be closely spaced when it is necessary to have high spatial resolution.

Measuring in extremely cold temperatures (–160 °C)

Type 4944‐W‐005 is a special microphone that is designed to handle measurements down to

–80 °C, which is perfect for use in, cryogenic wind tunnels.

WANT TO KNOW MORE?

For further details of the range, availability, and price, please use the link below to get in touch with your local Brüel & Kjær representative.

¡Pida asesoramiento a su representante de Brüel & Kjær!