WHAT YOU WILL LEARN

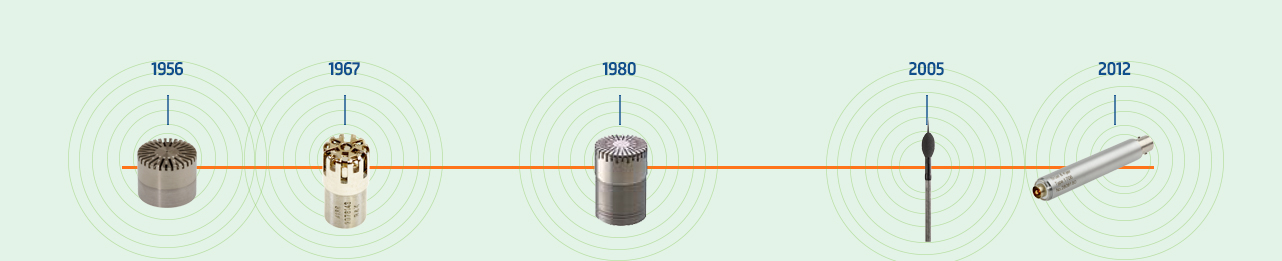

Brüel & Kjær began producing microphones in 1945. By the late 1950s they were established as a leading supplier of measurement microphones, due largely to the inspirational enthusiasm of Dr. Per V. Brüel in the field of microphone and general transducer development.

In parallel, Brüel & Kjær also invented, designed and developed complete acoustic measurement systems, analyzers and recorders. The accuracy achieved from our measurement microphones formed an important part in the success of these products.

From humble beginnings, Brüel & Kjær gained an increasingly good reputation amongst microphone users, both in the field of acoustics and in academic research, providing a high standard of service, well-built products and collaborative research and development programmes, ensuring a continuous improvement in the accuracy and performance of new instruments.

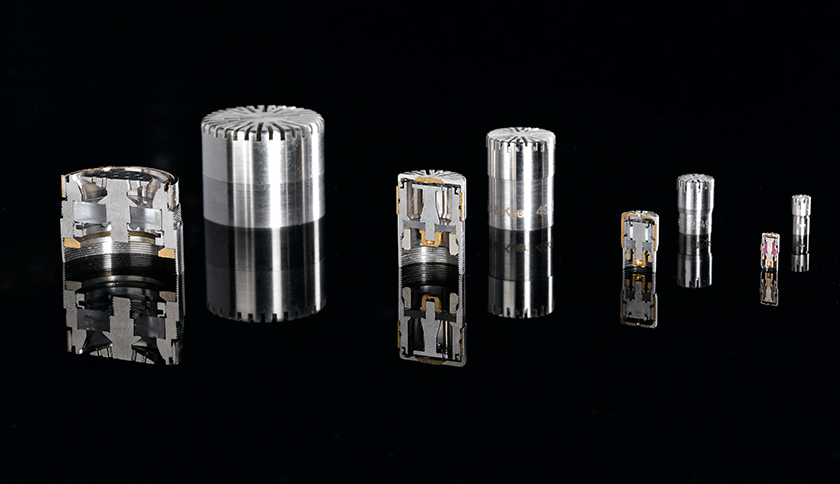

Today, this approach continues to deliver innovative measurement instrumentation, including a comprehensive range of measurement microphones in sizes from 1/8-inch to 1-inch. Together these microphones cover all aspects of measurement microphone usage.

By the early 1970s, Brüel & Kjær ’s strong presence in the measurement microphone field had become firmly established with the development of high sensitivity 1/2-inch microphones.

Calibration equipment, such as reciprocity equipment for laboratory calibration and the pioneering hand-held pistonphone, was released. This convenient way of calibration effectively improved the accuracy of everyday microphone usage by allowing users to check measurement accuracy in the field.

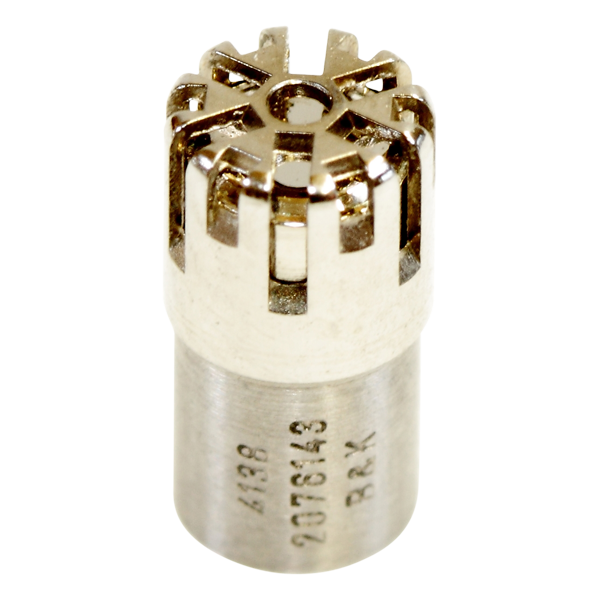

In 1973 Brüel & Kjær solidified the position as a leading microphone supplier, meeting a request from Western Electric to supply 1-inch microphones to replace their successful but ageing WE 640AA microphone.

The Brüel & Kjær solution took the form of the classic Type 4160 microphone.

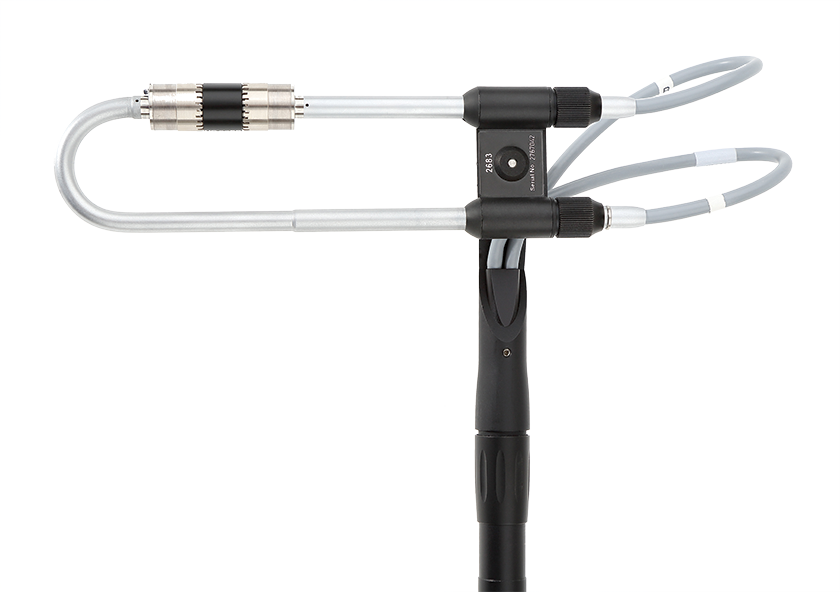

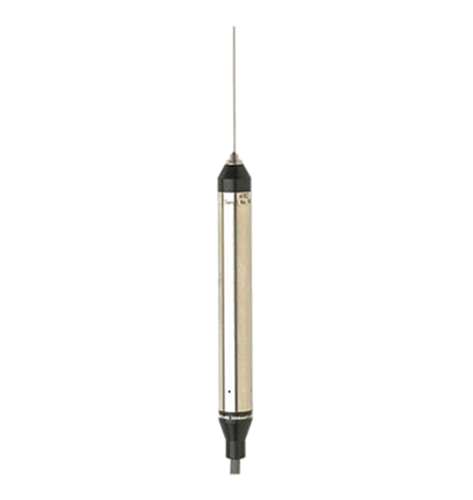

Fig.1.2 Sound Intensity probe using a phase-matched pair of microphones

Further innovations ensued, notably in improvements to electret processes during the 1970s, resulting in the production of stable prepolarized microphones which became standard for use with class 1 sound level meters.

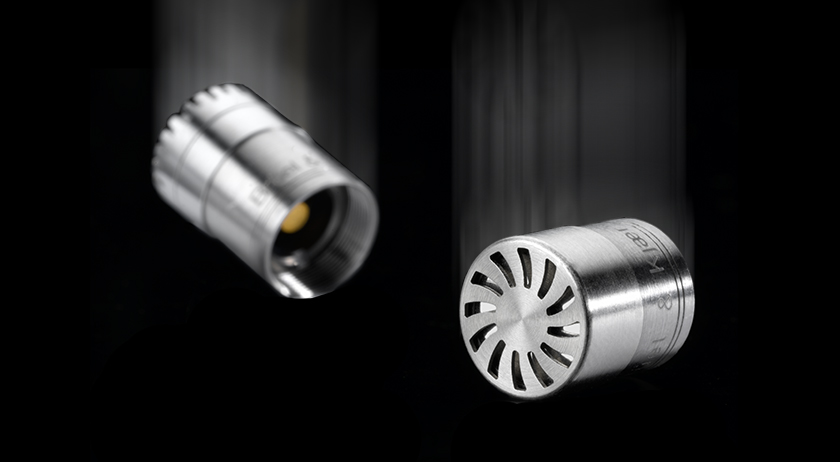

The 1980s brought further developments, in particular in the field of sound intensity measurement. The mid 1980s also saw the development of specialized types of sound intensity probe microphone. This microphone made use of a revolutionary and now patented tube system which gives a flat frequency response and allows for measurements in places where access for standard measurement microphones is difficult.

Improvements have continued into the 1990s with the introduction of highly accurate yet robust microphones (the Falcon RangeTM), and outdoor microphones and terminals for permanent outdoor noise monitoring. The outdoor microphones have since proven very effective in harsh environments.

MEASUREMENT MICROPHONES

Microphone Innovations

Development of Brüel & Kjær Microphones

Development of microphone products is performed by a dedicated team of engineers. This is something which is not easy to provide given the relatively small and specialist market for precision microphone products. However, at Brüel & Kjær this investment is seen as essential because it allows the design parameters and physical properties of microphones to be based on a solid foundation of knowledge, skills and experience.

Research and development work also encompasses a number of areas that reflect the different aspects of microphone design and construction, in particular, where highly accurate measurements need to be performed. These include:

- acoustic measurements, such as sound pressure and free-field reciprocity calibration

- mechanical engineering, for example, when controlling small mechanical tolerances

- electrical engineering, such as frequency analysis and capacitance measurements

- environmental testing, such as measurement of resistance to humidity and temperature tests.

Development skills and knowledge are also applied in research into the optimum choice of materials and to devise effective forms of testing microphones before they go into full production.

These tests include resistance to shock, vibration, temperature, humidity and in the case of preamplifiers, resistance to electromagnetic fields is also tested. Bump tests in which the microphone is subjected to repeated knocks simulate everyday use, while shock tests reproduce the possible effect of impacts received in transport (typically up to the equivalent of 1000 m/s2).

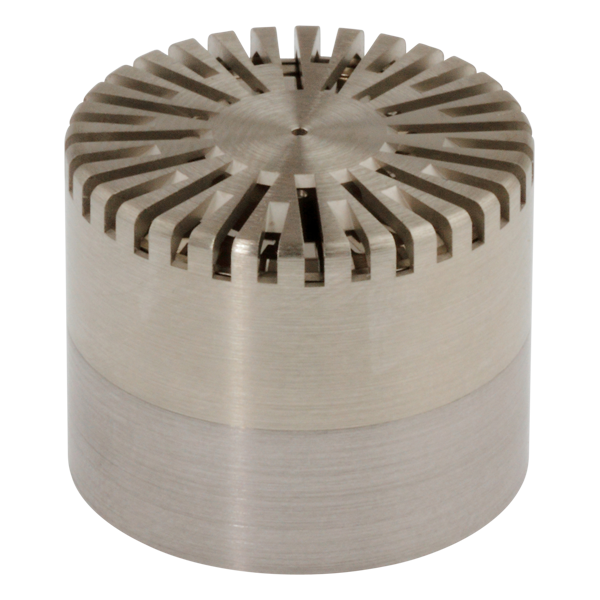

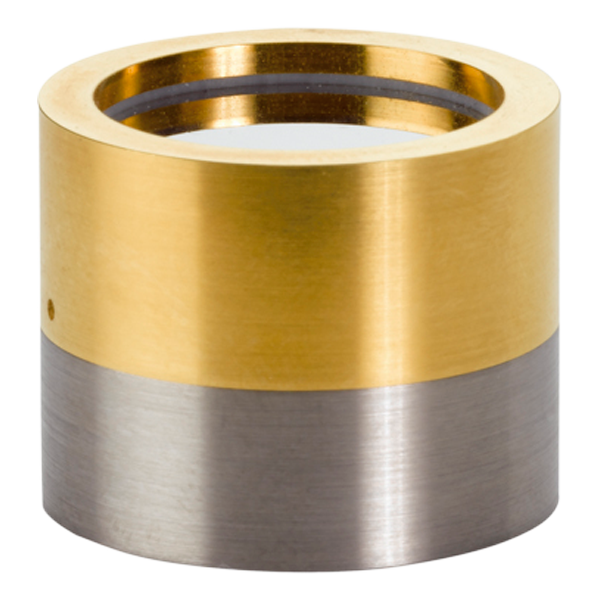

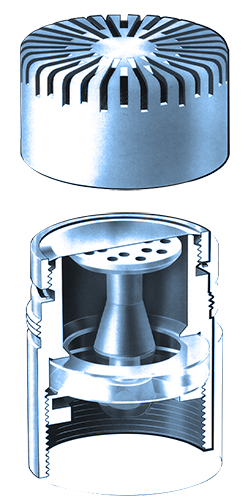

Fig.1.3 Design of a classic

condenser microphone

Finally, microphones are also tested for resistance to corrosion, as proven by the most recent range of condenser microphones which have been found to be very robust in harsh measurement environments.

Production of Microphones at Brüel & Kjær

Microphones are precision instruments and while the design of a conventional measurement microphone may appear to be quite simple, its production must be very precisely controlled to meet specified tolerances. Such tolerances impose great demands on the materials and construction methods used, yet the products created must be extremely reliable and robust.

SELECTING THE RIGHT

MICROPHONE (WEBINAR)

Speaker: Bin Liu

At Brüel & Kjær the emphasis is therefore on quality rather than mass-production.

Two components which receive a lot of attention during production are the microphone diaphragm and backplate. During production the surfaces of these components are made extremely smooth as a very high electrical field strength must exist across the diaphragm to backplate gap.

Another critical area of production is the distance between the microphone diaphragm and backplate which must be constructed to very small mechanical tolerances. Typically this is set to 20 µ with a tolerance of 0.5 µ. The required distance is monitored and then implemented precisely, once the correct tolerances have been adjusted.

Inscreva-se em nossa Newsletter e receba as últimas histórias do nosso mundo de ruído e vibração