In a production plant environment, the traditional method of auditing build quality is for drivers to subjectively evaluate the final product in real-life driving conditions. In the case of in-cabin wind noise, this is difficult and unrepeatable because of weather, traffic and varying road conditions. If a driver has a negative subjective impression at the end of the test route, the vehicle is held for further evaluation and further checks by a wind noise expert at the plant.

However, wait times for evaluation can be long and lead to delays in resolving any problems.

SONOSCOUT

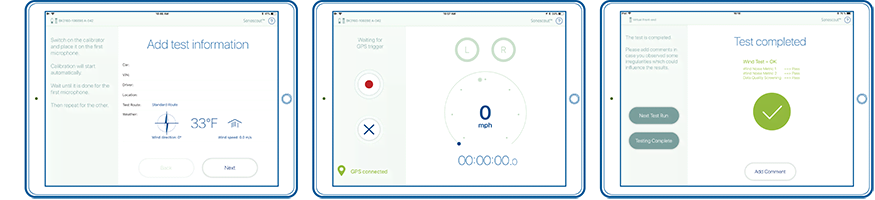

To address these issues, and to increase the pace at which the root cause of wind noise concerns can be identified and remedied in the manufacturing process, a portable tool, the Sonoscout Vehicle Audit System (Sonoscout VAS) has been developed.

Sonoscout VAS is specifically designed to seamlessly integrate into existing processes. When applied, the system can quantify the wind noise performance of a vehicle in a real-world environment, acquire repeatable, objective data and provide real-time results on the performance of the vehicle.

The algorithms implemented in Sonoscout VAS allows OEMs to automate data acquisition, assess the quality of the data, compute wind noise metrics and produce pass/fail results based on sound quality metrics and a frequency-based octave analysis. All this when the vehicle is driven by a non-NVH trained operator over public roads.

Abonnez-vous à notre Newsletter et recevez les dernières actualités en acoustique et vibrations