The aviation industry is facing stringent requirements to reduce its environmental footprint. But technological innovation and development – from concept to certified product – can take decades.

In fact, the aircraft of 2050 is now under study within the framework of R&T programs and faces a long schedule of ground and flying demonstrations before they can be approved to safely carry passengers.

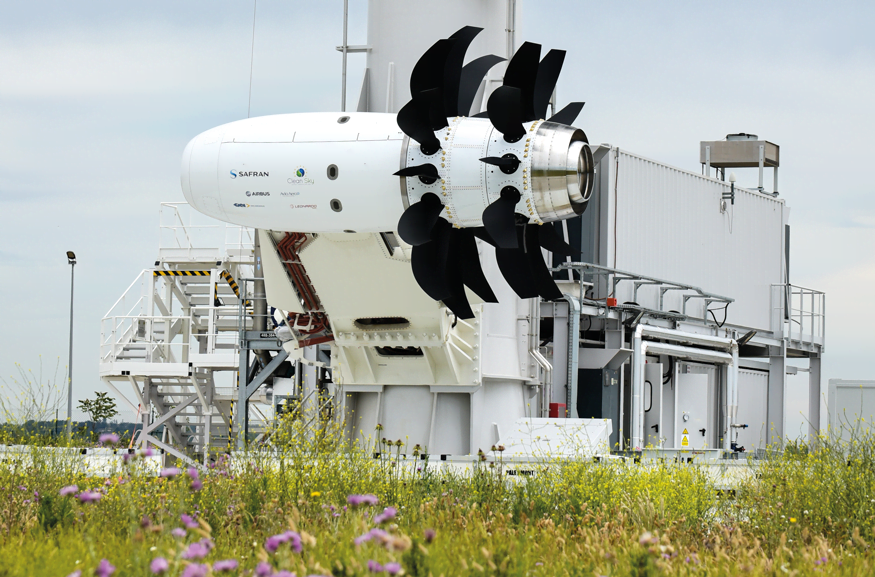

Safran Aircraft Engines' Open Rotor demonstrator, developed through the European Clean Sky R&D initiative, is part of Safran Aircraft Engines' plans to develop a propulsion system that will meet the needs of aircraft manufacturers in 2030. The Open Rotor configuration aims at meeting several technological challenges such as a new propulsion mode, an innovative aerodynamic configuration, and unprecedented manufacturing processes.

Clean Sky encompasses six so-called Integrated Technology Demonstrators (ITDs). Leading the SAGE (Sustainable And Green Engine) ITD of Clean Sky, Safran Aircraft Engines, together with its industry partners, aimed to deliver and ground test a full-scale Open Rotor engine. Now, following eight years of development, Safran Aircraft Engines has successfully performed its first ground test of the Open Rotor demonstrator at its brand-new, purpose-built, open-air test bench in Istres, southern France.

Testing a demonstrator – a complex affair

Testing is an essential part of this groundbreaking project, and with a pioneering new design like the Open Rotor, this is no small affair. With the revolutionary unshrouded engine architecture, use of cutting edge new materials, and innovative manufacturing processes, the engine test must capture all manner of dynamic data to both ensure the reliability and integrity of the test, and to provide the reams of data for design analysts to ponder. For this, Safran Aircraft Engines test engineers utilized the Brüel & Kjær gas turbine test solution, that had earlier proven its worth in the even larger scale tests run during certification of CFM's LEAP* engine.Testing requires instrumenting the engine with a multitude of different sensors to measure, monitor, and record engine behavior. High-performance data acquisition equipment placed in containers right next to the motor base collects the data and transfers it to the 600 m2 technical center through a network of 10000 m of fiber optic cables.

When putting a prototype engine through its operating envelope, the dynamic and vibratory aspects of the open rotor prototype engine need to be followed very closely to maintain the integrity of the engine throughout the testing period. Engineers sit at some thirteen monitoring stations to closely follow the vibration and dynamic response in real-time. All data acquired is then sent directly to Safran Aircraft Engines' design offices in Villaroche for post-test analysis. Being able to share data easily between sites accelerates the process of the data assessment and decision making.

* LEAP is a trademark of CFM International, a 50/50 joint company between GE and Safran Aircraft Engines

Configuring it out – fast, easy, and foolproof

Before any test can be performed, engineers must complete the complex task of pre-test planning and set-up, which consists of two potentially time-consuming phases. The first phase involves defining the many different sensor types and measurement aspects. A lot of upfront information needs collating from the test team and then configured into the test system. This can be a laborious finicky exercise, which is a prerequisite for a successful test but ripe for introducing errors. By collating this data into one Microsoft® Excel® file during the planning phase, Safran Aircraft Engines could simply load it into the master data acquisition PC and set up the entire system. The spreadsheet contains all the defined parameters for time recording and processing of the signals, as well as all sensors with their measurement characteristics. Additionally, it contains all the set-ups for the data monitoring terminals, and the alarm monitoring system that can signal alarms to the testbed pilot and test operators.

LEARN MORE

LAN-XI Hardware Unit

The second phase consists of physically connecting the many hundreds of channels of diverse data such as vibration, strain, pressure, and dynamic displacement to the acquisition system. This can be a complex affair of sorting out what goes where and how. However, as the system is built around Brüel & Kjær’s LAN-XI hardware unit, which has no channel binding, any channel can be connected to any input.

This provides flexibility when configuring the system and saves time, as there is no need to designate specific sensor types to specific data acquisition types. The same data acquisition system input plug can accept all types of transducers, again easing set-up, and providing versatility.

Keeping tabs on the test

Keeping a close eye on things during all stages of the test is important to ensure the validity of the test and to confirm that dynamic parameters remain within limits. Engineering teams monitor vital parameters in real-time to safeguard the integrity of the engine. Real-time alarms can warn of limit breaches, and logbooks keep a record of the test process.

The individual engineering teams who track the acquired signals have very different needs in terms of visualization and data processing. Each monitoring station is, therefore, configured independently providing each department with only those signals relevant to their respective applications. Data is available in real-time and a wide range of measurement displays are available to feed the right information to the right people at the right time. Data can be meticulously processed immediately or played back during or immediately after each test so that each phase of testing can be analyzed and evaluated before moving on to the next.

Sharing data when and where needed

Many parts of the test organization need access to data as and when it is recorded. The independent monitoring stations can be configured individually for the specific investigation, so partners and clients can be provided with full access to their own proprietary data. With many different people involved looking at very specific and different parts of the engine, it is of utmost importance that test engineers learn how to use the system quickly with a minimum of training.One of the test engineers concludes, “It was extremely easy to explain the use of the system in a very short time to all different engineering departments and partners”.

Data needs to be shared on-the-fly with off-site departments in specific formats. Study departments at Villaroche can access test data the same day. The same engineer adds,

“The real-time conversion to datx format and the speed with which data is transferred to the engineering office is unbeatable”. Following four days of testing on the open rotor, we asked an engineer returning from the site what he thought of the dynamic data acquisition system provided in Istres. His reply was encouraging, “I have nothing special to say; it did everything I wanted it to do. What else can I ask for?”

A short pause and he adds, “I just wish that I could do the same real-time analysis from my office because a lot of my time was spent on-site waiting for the engine to rotate.”For Safran Aircraft Engines, the overall results of this first phase of testing were promising.

The next phase will bring new challenges, but each step of the program represents a huge stride forward towards a greener, cleaner sky.

The value of COTS

The rapid availability, lower costs, and low risk of COTS (commercial off the shelf) products make them great alternatives to their custom-built equivalents. Safran Aircraft Engines test engineers agree, “Using both COTS hardware and software provided a faster resolution of hardware issues, faster upgrades, reduced support costs and opened up a wealth of standard analysis features for further investigations.”

Related Articles

Iscriviti alla nostra Newsletter e ricevi le informazioni più recenti dal mondo del suoni e delle vibrazioni