Applicazioni

Abbiamo suddiviso i settori di applicazione dei nostri prodotti in aree che riflettono accuratamente casi d'uso e bisogni specifici. Per qualsiasi domanda potete contattare i vostri rappresentanti locali Brüel & Kjær.

-

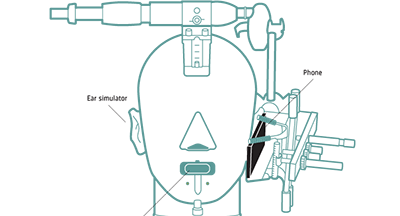

Electroacoustics

To deliver quality sound, it is essential to analyze the sound produced and captured during R&D. A multitude of parameters are critical to authentic sound reproduction.

-

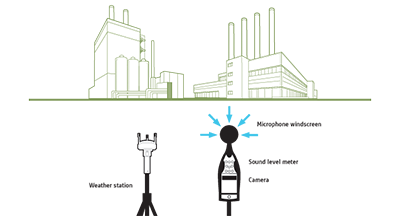

Environmental Noise

By measuring and mapping environmental noise, and general noise pollution, we can limit the impact of noise on health, and improve the quality of life for humans and animals.

-

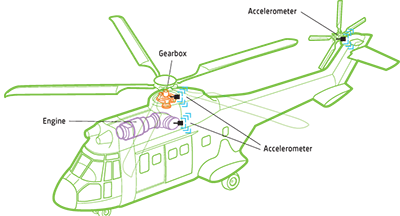

Machine Analysis and Diagnostics

Machine analysis and diagnostics help you identify energy emissions caused by noise and vibration, which could explain inefficiency in machinery.

-

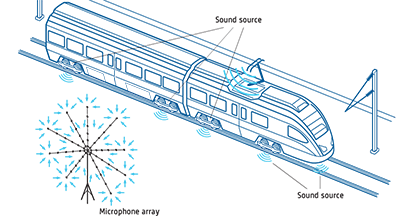

Noise Source Identification

By tracing noise back to very specific components, engineers can target their mitigation efforts more precisely.

-

Acoustic Holography

-

Underwater Acoustic Ranging

-

Wind Tunnel Acoustic Testing – Aerospace

-

Wind Tunnel Testing For Cars

-

Beamforming

-

Flight Certification

-

Flyover Noise Source Identification

-

Real-Time Noise Source Identification With Acoustic Camera

-

Ramp Noise Testing

-

Sound Intensity Mapping

-

Spherical Beamforming

-

Static Engine Noise Certification

-

-

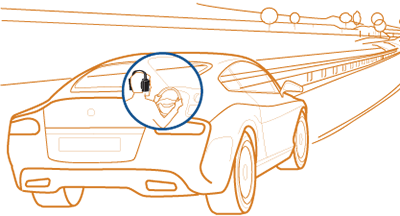

NVH - Noise Vibration and Harshness

The combined noise, vibration and harshness - NVH - is immediately apparent when car drivers assess the ‘feel’ of a vehicle.

-

Production Testing and Quality Assurance

Effective production testing ensures customer acceptance and maintains product brand value, production line yield and cost effectiveness by ensuring that finished products comply with the expectations set during R&D, that product quality is consistent and that root causes for faults are mitigated.

-

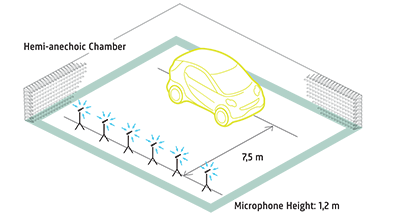

Product Noise

Product noise and sound emission need to be designed with both the user’s subjective experience and objective parameters in mind. Here’s how we can help.

-

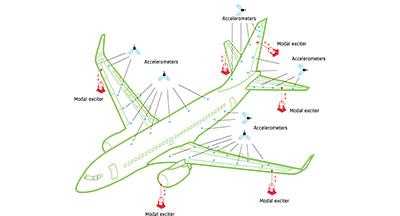

Dinamiche strutturali

Tutte le strutture sono soggette a forze fisiche che influenzano le loro prestazioni. Queste strutture devono presentare il giusto compromesso fra elasticità e resistenza, senza essere sovradimensionate.

-

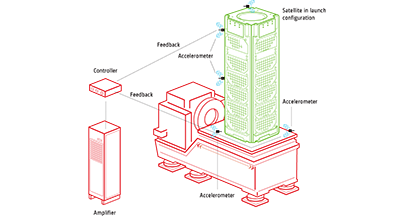

Vibration Testing and Validation

Through vibration testing we can condense a lifetime of stress and wear into a short period of time, reveal hidden design weaknesses and validate durability.