Because of its relatively low levels of CO2 emissions, train travel is considered one of the most environmentally friendly methods of transportation. In fact, according to the Green Jobs Initiative, part of the United Nations Environment Programme (UNEP), the railway is one of the key sectors in the goal to achieve sustained social and economic growth, compatible with climate stabilization.

High-speed trains are one of the most eco-friendly ways to travel thanks to their extremely high capacity and efficiency. High-speed trains also offer comfort and safety to travellers and a great opportunity to railway operators looking for competitive services to add to their portfolio.

The high-speed challenge

The one drawback of high-speed trains is that they are extremely loud. Construcciones y Auxiliar de Ferrocarriles (CAF) is a global leader in the manufacture and supply of high-tech rolling stock based in Beasain, Spain. They developed the OARIS solution, a family of high-speed trains capable of reaching 350 km/h. Isaac Gutiérrez, R & D Engineer at CAF, explains, “The European Technical Specifications for Interoperability (TSI) has set maximum pass-by noise levels for high-speed trains. This is to ensure that people who live in the pass-by communities are not burdened by ridiculously high noise levels. Because of these requirements, high-speed trains are not allowed to run at night. We are constantly working to reduce the rolling and aerodynamic noise generated by the train, to help operators extend the daily operative time and make the service more viable.”

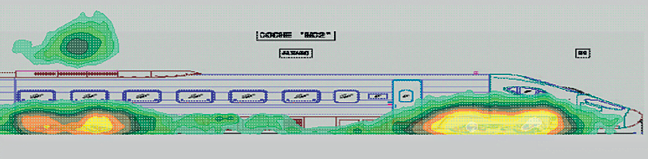

The art of the noise map

CAF creates noise maps that help them identify and focus on the train’s various noise sources. The rolling noise is the noise produced by the wheels, rail and sleepers and is generated by the wheel-rail contact. The aerodynamic noise is the noise generated by air passing over the train’s exterior shapes and irregularities, such as the front nose, the first bogie, the inter-coach gangways and the pantograph.

“Aerodynamic noise is the most important noise contributor to the overall pass-by noise level and is the most challenging to measure and understand. We were looking for the most accurate way to do this, in order to make relevant adjustments to our train design and meet the European TSI requirements,” says Isaac.

Beaming it in

Mario Menendez, Isaac’s Brüel & Kjær counterpart, said CAF’s challenge was quite clear. “The acoustic dynamic range of a high-speed train passing by is massive.

In just a few seconds you go from almost complete silence to extremely high noise levels. Measuring this noise requires a wide dynamic range acquisition system capable of recording both low and high noise levels with the same precision and at a very high sampling rate. Our beamforming technology can do this.”

“We had been working with Brüel & Kjær for 20 years and we were aware of their beamforming technology,” says Isaac, “but we had never applied it before. When Mario suggested we use it, we decided it was the best option, as we trusted the equipment and Mario and his team.”

Let the measuring begin

Isaac and Mario set up their beamforming system at pass-by sites across the Spanish countryside,with the on-site support of Vincent Raisseix, a Brüel & Kjær Application Engineer. “Our Rail Vehicle Moving Source Beamforming System is based on the PULSE™ platform,” Mario explains. “The system follows a linear movement parallel to the planar microphone array and enables speed-position calculation from a pulse speed signal or photocells.”

The microphone array has nine arms – each with six microphones fitted with windscreens to minimize the effect of air turbulence on the train pass. The signals from all 54 microphones are fed to a multichannel PULSE LAN-XI system that simultaneously records the raw signals at a sample of more than 65 kHz per channel. “This high sample rate allows you to make any type of signal processing or hear any microphone signal in very high quality,” says Mario.

Precise planning and preparation

Although the equipment and methodology were top-class, the project was not without challenges. “These types of pass-by tests need to be done at night when the high-speed railway has no traffic,” says Isaac. “Yet the instrumentation needs to be deployed, calibrated and tested during the day when the railway is active. As you can imagine, this presents some serious safety challenges and requirements that need to be met.” “You also have the challenge of limited time and budget,” adds Mario. “All measurements and recordings need to be right the first time – there is no room for overloads, system failures, or missing or defective items.” To ensure these challenges were met, CAF and Brüel & Kjær carefully planned the project and all instruments were tested in advance.

The results: A quieter ride

The project resulted in noise maps indicating sound pressure, pressure contribution density and sound intensity for the whole and individual parts of the train. “From studying the noise maps, we have determined that we, for example, could modify the shape of the cars to change the direction of the air passing between the cars. By making this modification, we were able to reduce the exterior noise by 3 to 5 dB(A). We are confident that no other noise measurement system could have helped us achieve this.” This is exactly the data CAF needs to be highly competitive in the high-speed train manufacturing game. “If we can achieve quieter high-speed trains, the trains can run at night, making them a more viable option for travellers and a more profitable service for operators,” Isaac explains. “This is why high-speed noise reduction has become a strategic area for CAF – and why our collaboration with Brüel & Kjær is so important to us.”

뉴스레터를 구독하고 소리와 진동에 대한 최신 이야기를 만나보세요