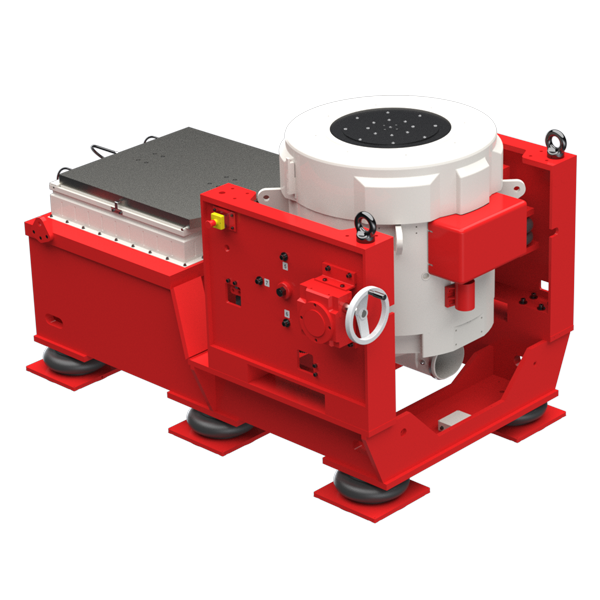

LDS V8800

Medium-Force Shaker

An air-cooled shaker system for vibration and mechanical shock testing with sinusoidal, random, or transient excitation. For payloads up to 700 kg (1540 lb), such as electric vehicle (EV) battery cells and modules, nanosatellite, satellite, and component testing, or component and subsystem durability tests. With a peak sine force rating of 59 kN (13,250 lbf) and a max. shock force of up to 175 kN (39,340 lbf).

Demande de devisFlexible, powerful and energy efficient, the LDS® V8800 + XPA-K shaker system takes vibration and mechanical shock testing to a new level. The system provides high shock performance as a standard, opening up new applications and eliminating the need for a matching transformer.

LDS’s Inductive Centring System (ICS) guarantees increased efficiency and accuracy, while the COOL and QUIET modes minimize the system’s carbon footprint. Remote service capabilities reduce downtime and ensure low inspection risks.

The LDS® V8800 series shaker system is used within the automotive, aerospace and defence, transport and packaging industries for a variety of R&D, testing, and production scenarios including general load testing, product qualification and packaging testing. It is suitable for high-acceleration shock tests, as well as for testing with sinusoidal, random and transient excitations.

USE SCENARIOS

- Qualification testing of automotive parts and systems, including industry standards such as ISO/TS 16949, and buzz squeak and rattle tests

- Electronic assembly and computer equipment testing

- Avionics and military hardware testing, such as Mechanical Environmental Tests AECTP 400, MIL-STD and AS9000 standard tests

- Telecommunication and satellite component testing

- General stress screening, including ISO 5344, HALT, ALT and HASS

- Product and package testing, such as ISTA and ASTM 4169 tests

- Shock and transient test applications

- Environmental testing with AGREE chambers, Combined Environmental Reliability Test (CERT) and others

CHARACTERISTICS

With its improved shock performance, the LDS V8800 medium-force shaker meets today’s industry and market requirements with sensibly sized payloads in standard configurations. A matching transformer is no longer required, saving cost while at the same time improving reliability and performance.

The LDS V8800 + XPA-K shaker system fulfills the following shock test specifications: 150 g 0.5 ms, 150 g 6 ms, 100 g 11 ms, 100 g 6 ms, 50 g 11 ms and 50 g 6 ms).

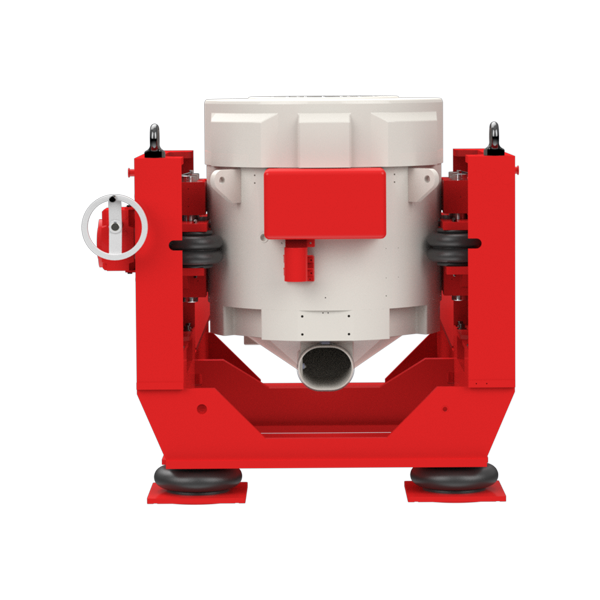

The shaker’s Inductive Centring System (ICS) is immune to unfavourable environmental conditions such as dust or heat. This not only eliminates the need for regular calibration and sensor maintenance, but also increases the reliability and efficiency of the V8800 + XPA-K shaker system.

The system features two energy consumption modes, which can easily be controlled via the XPA-K amplifier’s user interface. The COOL mode automatically adjusts system settings to reduce the power consumption required for a test while the QUIET mode operates the shaker without a fan at low power to reduce noise.

The status of the shaker system is continuously monitored. This data is stored in for analysis and to support preventive maintenance and fault detection. It is also accessible to system users in real-time via the amplifier’s touchscreen.

ADDITIONAL CAPABILITIES

V8800 shakers are available with different XPA-K amplifier systems. Choose 64 kVA for maximum sine and random performance, or 88 kVA for enhanced shock performance.

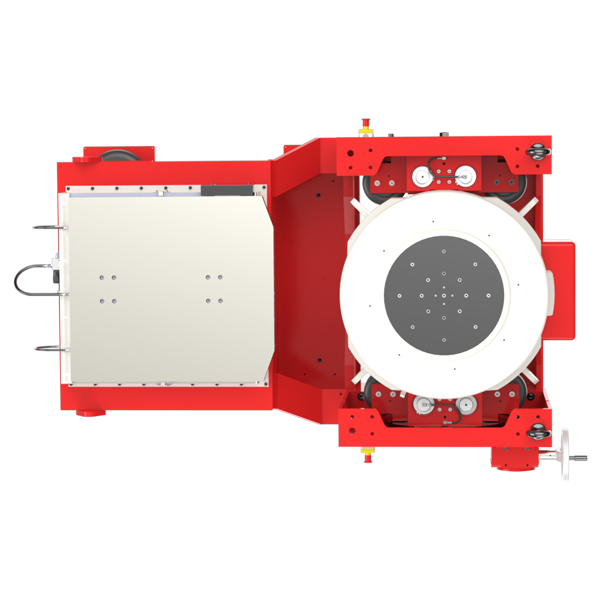

The systems can be adjusted to your specific needs, for example, with guided and unguided head expanders as well as air glides and thermal management systems. As standard, the systems are mounted on an air-isolation trunnion with body rotation gearbox combined with a slip table to enable horizontal as well as vertical vibration, but they can also be base-mounted for under-chamber operation.

The LDS V8800 shaker system is compatible with environmental testing equipment, including AGREE chambers.

- Sine force peak

- 59 kN

- Max random force RMS

- 66.0 kN

- Max acceleration sine peak

- 140 g

- Velocity sine peak

- 2 m/s

- Displacement continous pk-pk

- 76.2 mm

- Moving element mass

- 43.0 kg

- Usable frequency range

- 5 – 3000 Hz

Abonnez-vous à notre Newsletter et recevez les dernières actualités en acoustique et vibrations