BATZ, global supplier of solutions for the automotive sector

BATZ uses HBK equipment for testing according to its customers’ requirements

CHALLENGE

The automotive industry is undergoing continuous change, always looking to the future. This is particularly true in the current situation where there is significant uncertainty about the vehicles of the future. However, demands for passenger comfort continue to play an important role with reducing noise levels an important factor to achieve this. First-tier manufacturers such as BATZ conduct tests in their own facilities and need the right equipment to present customers with objective and reliable data that respond to their specifications.

SOLUTION

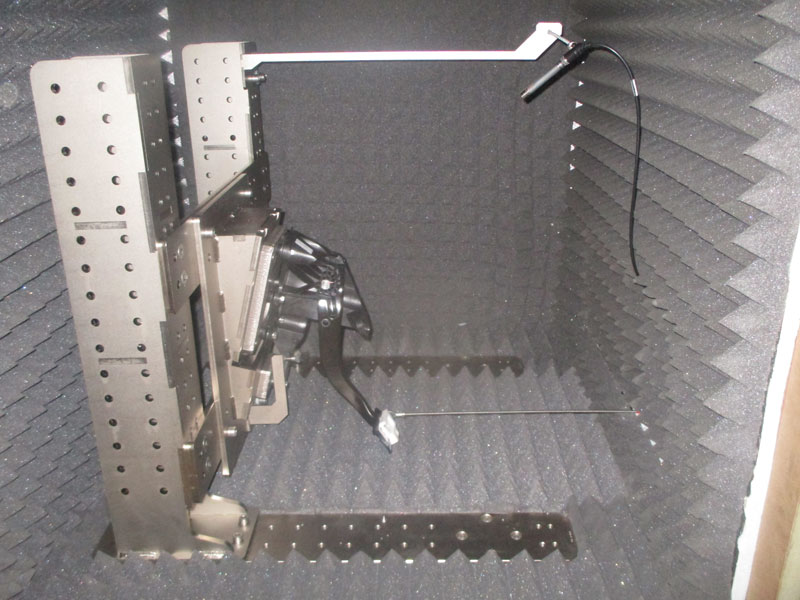

To respond to a customer’s need for reliable noise level data when operating a brake, accelerator or clutch pedal, BATZ decided to turn to HBK, the leading sound and vibration partner . HBK equipment is integrated into a soundproofed hood to collect sound data when the pedal assembly is operated manually. This data can then be compared with the customer’s requirements.

RESULTS

With HBK test equipment, BATZ is not only able to respond to its customer with guarantees, but is also equipped for a future where it is predicted that these types of tests will continue on an upward trend. The equipment’s reliability, quality and simplicity of operation are the characteristics most valued by BATZ engineers, who also appreciate the availability of HBK experts, who are always ready to assist in the testing process and interpretation of results.

BATZ Group is a global industrial group that provides specialist solutions for the mobility sector, based on knowledge, technology, and innovation. Founded in 1963, with headquarters in Igorre, in the Basque Country, northern Spain, BATZ is part of the Mondragón Corporation, one of the largest industrial cooperative groups in the world.

BATZ conducts its business in the fields of mass production and die making, and is a leading company in the design and manufacture of light composite structures using new materials and processes, as well as active aerodynamic components such as a car’s front grillers or slippers. This together with BATZ’ experience and prestige in the design and manufacture of mechanical and mechatronic control systems, has made the company a top-tier supplier to the main automotive OEMs. BATZ also develops solutions for the implementation of new advanced materials by improving its hot and cold forming processes using a wide range of steels and aluminium, and offering a comprehensive service ranging from the conceptual design of the product to its commissioning.

Just like the automotive sector, BATZ works with an eye to the future and is always attentive to the manufacturing industry. For example, to reduce CO2 emissions, BATZ works on solutions using new advanced metal and non-metal materials to lighten structures, and to optimise the aerodynamic and thermal efficiency of vehicles. BATZ also develops functionalities relating to safety and ergonomics based on mechanical and mechatronic solutions. Another aspect generating growing interest in vehicle manufacture is that of in-cabin noise. Customers are becoming increasingly demanding, with interior comfort – where reducing noise plays an important role – high on the list of requirements.

Noise is a factor that has become increasingly important in recent years, as manufacturers work harder and harder to differentiate themselves from their competition and provide both drivers and passengers with the best driving experience and comfort. In addition, due to social and environmental demands, noise emissions are subject to strict regulations with the arrival of the quieter electric and hybrid powertrains accentuating every sound.

The industry must respond to the user’s subjective perception. However, this response should be based on objective data and noise, and therefore, these must be taken into consideration from the design phase of parts and components. It is here where BATZ turns to HBK’s experience and equipment to help meet the demanding requirements of its customers.

BATZ needed to control the noise level of one of its pedal assemblies, an assembly that includes the clutch, brake and accelerator pedals. The pedal assembly is designed and manufactured at the BATZ facility, where noise testing is a recent addition. Until now the testing department had been performing many types of load application tests, climate tests as well as other types of measurements, but now, with the inclusion of HBK equipment, BATZ has begun to conduct noise tests at its own facilities.

These tests consist of manually operating the pedals of a pedal assembly and checking if the noise generated meets customer requirements. When operating the pedal, noise is generated at different conditions , and this is where HBK equipment comes into play. As BATZ have very little experience in noise testing, the ease-of-use of HBK equipment and the availability of application specialists to assist in the testing process and interpretation of the results, is highly valued.

BATZ is using the LAN XI Acquisition Hardware and BK Connect Data Processing platform together with HBK Microphone Type 4961-H-041 and Uniaxial Accelerometer Type 4534-B for sound and vibration testing. For the acoustical test the microphone is installed on a test bench where the pedal assembly is operated within a soundproofed hood. The pedal is manually operated from outside, the emitted noise measured and then processed with tools like overall value vs time, 1/3 octave spectrum and some psychoacoustic metrics depending on the required test specifications. The vibrational testing is mainly Frequency Response Function (FRF) measurements using Impact Hammer Type 8206-003 and uniaxial accelerometer Type 4534-B. All processing tools are available in the BK Connect data processing software.

BATZ has experienced that the demand for noise measurements is increasing and will continue to grow. By having their own resources to make these measurements and avoiding having to subcontract these types of services not only leads to a cost reduction, but also to better control over the entire process – from the design and manufacture of an assembly to the delivery to the end customer. However, even though noise has always been a factor, it has often been analysed with the subjectivity of the human ear. Now, with the inclusion of HBK equipment, objective data can be collected for comparison with customer requirements.

뉴스레터를 구독하고 소리와 진동에 대한 최신 이야기를 만나보세요