Vibration Meters / Vibration Analyzers

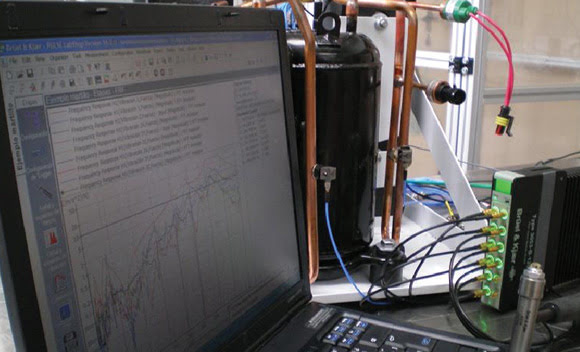

Vibration Meters and vibration analyzer Type 2250‐W and 2270‐W are innovative, 4th generation analyzers from Brüel & Kjær. Both instruments feature an award‐winning design based on extensive research amongst sound and vibration technicians, engineers, and consultants. The vibration instruments and analyzers deliver a flexible platform, which is easily customized with software and modules for collecting, recording, and analyzing vibration data.

-

Type 2270-W

2-Channel Vibration Meter / Vibration Analyzer

Type 2270 is our flagship, two-channel vibration meter and vibration analyzer, and is designed for advanced measurement capabilities while providing the flexibility to perform simultaneous sound and vibration measurements.

-

B&K Type 2250-W

SINGLE-CHANNEL VIBRATION METER/ VIBRATION ANALYZER

Type 2250-W is a single-channel vibration meter and vibration analyzer designed for basic and advanced vibration measurement and analysis. Important update: Type 2250-W will be transitioned to the B&K 2245 and HBK 2255 product families, which are designed for basic and advanced measurement and analysis.

WHAT IS A VIBRATION METER

A vibration meter is a vibration measuring instrument – often handheld – used in product development and manufacturing for vibration assessment, diagnostics, and quality control.

A vibration meter can feature a range of analysis options, from simple broadband measurements to an octave or FFT-based frequency analysis and even time-domain integration to velocity and displacement. Single, wide-frequency band measurements are useful to quickly see the vibration indicator, used when evaluating the general condition of a machine or the effectiveness of vibration isolation measures.

WHAT IS A VIBRATION METER USED FOR

A Vibration Meter and analyzer is used for diagnostic purposes in the course of product development, frequency analysis of vibration to provide essential insights to product performance. Some frequency components in the vibration frequency spectrum can be immediately related to particular forcing functions, for example, shaft rotation speeds, gear tooth meshing frequencies, etc.

Acceleration, velocity, and displacement are parameters traditionally used to assess a machine's health when initially installed or after maintenance, repair, or overhaul (MRO). Expanding on this, the Crest Factor is used to detect and diagnose defects in roller element bearings.

VIBRATION METER APPLICATIONS

- Crest factor measurements

- Quality testing and inspection

- Product development

- Machine analysis and diagnostics

- Building vibration

- Maintenance, repair, and overhaul (MRO)