In a world where speed and power dominate, tight development schedules mean that time is critical. Noise analysis and vibration testing within the aerospace and defence industry must be accomplished in a short time window and produce accurate data that is stored safely and securely. The complex and expensive test objects are not always readily available and the test phase often requires massive resources, so it is imperative that testing is successful the first time.

Lockheed Martin’s core business areas include aeronautics, missile and fire control, and space systems, and the collaboration with Brüel & Kjær has included noise analysis tests for the F-35 fighter jet programme and vibration testing solutions for fighter jets, missiles and satellites.

Global partnerships

It is in Fort Worth, Texas, famous for its frontier atmosphere, that Lockheed Martin’s sophisticated fifth generation combat aircraft is being manufactured. Creating an unprecedented fighter jet takes unprecedented collaboration and many different global partnerships have helped to create the F-35 Lightning II – a fifth generation, multirole fighter. It is perhaps little known that the world’s best acoustic experts from Brüel & Kjær have contributed to the development of this aircraft.

One of the F-35 acoustic engineers at Lockheed Martin is Egbert Hood and he has been working with Brüel & Kjær for the last 5 years: “The acoustic specialists at Brüel & Kjær really understand our requirements and have impressed me with their ability to foresee our software and hardware needs, enabling us to stay aware of what is going on in the industry.

“Brüel & Kjær has also provided us with valuable remote support – even in one instance helping me to reconfigure the noise analysis system out in the field so that we could continue testing.”

Egbert Hood adds, “As a whole, the F-35 programme is testing many different aspects of the jet fighter, and we are working with a great many people. For noise analysis around the aircraft, we can’t dictate the testing schedule or redo an acoustics test, so it’s important the hardware and software is reliable and that we get the testing right the first time. I’m happy to say that with Brüel & Kjær, we have been able to do this.”

Acoustic footprints in all conditions

The single-engine F-35 is manufactured in three versions:

- F-35A conventional take-off and landing (CTOL)

- F-35B short take-off/vertical landing (STOVL)

- F-35C carrier variant (CV)

All variants of the F-35 Lightning II use the world’s most powerful fighter engine, the Pratt & Whitney F135. For the F-35B variant, the short take-off and vertical landing functionality gives the unique ability to operate from a variety of ships, roads and frontline combat zones, providing flexibility in many scenarios.

Similar to a helicopter that before landing can fly stationary, just above the ground, the F-35B short take-off/vertical landing (STOVL) variant has the ability to hover. This is made possible through the Rolls-Royce patented shaft-driven LiftFan® propulsion system and an engine exhaust nozzle that can swivel 90 degrees when in STOVL mode.The Rolls-Royce LiftSystem® is the first to enable STOVL operations for supersonic-capable aircraft. Ground crew working in close proximity to these jets are exposed to more noise than

Noise exposure is a challenge for ground personnel who work in close proximity to this aircraft, for example on aircraft carrier decks. It means that the fighter jet comes in vertically (which requires a lot of power) and the support crew can be standing below it, therefore getting more noise exposure compared to a conventional take-off/landing.

As part of the F-35 programme, Lockheed Martin started using a Ramp Noise solution based on Brüel & Kjær’s PULSE platform, which was later supplemented with the PULSE Reflex post-analysis software. “We started in 2009 with the LabShop software and around 75 microphones,” explains Egbert. “Since then, we have had multiple test periods, analysing noise using different configurations of microphones. We are gathering information about noise close to the fighter jet during various manoeuvres and during particular aspects of the F-35 operation.”

The integrated solution involves some 65–75 microphones laid out over the runway. The noise signals are collected by high-performance data acquisition hardware and the data is delivered to powerful analysis software, where the measurements can be easily reviewed and analysed.

One of the goals was to establish the acoustic footprint of the three F-35 variants, under all relevant operational conditions from take-off, landing, taxiing and fly-over, to the most challenging of them all: ‘hovering’. The solution was used to seamlessly acquire and analyse a large amount of data for all F-35 variants under the different conditions, establishing the various noise footprints and helping to ensure noise exposure is limited within all these environments.

“It’s a testament to Brüel & Kjær equipment that we are still using the same microphones that we started with and they are still working very well,” explains Egbert Hood. “Over the years, the data acquisition has vastly improved. In the beginning, we used to review data at the end of a testing day and it would take a long time to process. With the latest data acquisition software, analysis times are so quick that we can process and review data during the actual testing. We really appreciate this increased efficiency and additional flexibility, and we have high confidence in the results that we receive.” These results are used to inform decisions about the right hearing protection for ground crew and, for example, to define areas around the aircraft where certain actions should not occur.

Ramp Noise testing

Civil aviation authorities require Ramp Noise testing but it is not a military requirement. The F-35 programme, however, carries out Ramp Noise testing to protect personnel from noise exposure.

- Used traditionally for civil aircraft when parked on the runway, since aircraft can still be noisy even when only auxiliary engines are running

- Evaluates the noise exposure of aircraft personnel and ground crew

- Maps where the noise is coming from and the noise patterns

- High-quality testing has greater significance as

new materials and new designs are assessed for exterior noise

Vibration testing demanding applications

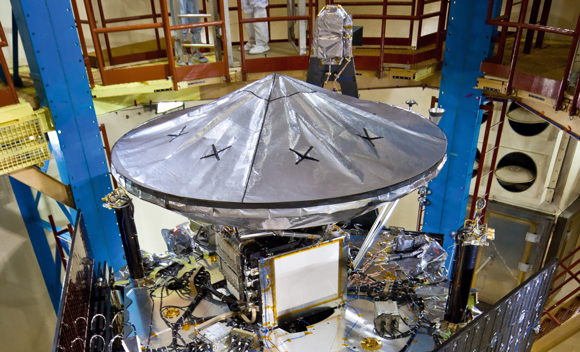

Lockheed Martin uses specialized domain expertise across all of its core business areas and Brüel & Kjær has not only been helping with acoustics but also when it comes to complex vibration testing to ensure the integrity and reliability of fighter jets, missiles and satellites. Extensive product qualification tests and stress screening tests are carried out to make sure that these demanding applications can sustain launch condition, deployment, transport, and long-term operation.

Vibration test solutions are in place for durability testing, stress screening and R&D qualification testing. Lockheed Martin has been putting the F-35 systems through exhaustive vibration test programmes and some of Brüel & Kjær’s large V9x water-cooled LDS shakers (V984) are being used, for example, to test missile assemblies in Lufkin.

For space systems, the shakers test to ensure that the different components can survive the rigours of a launch. Recording the data is a critical component of vibration testing and data acquisition is needed to measure what’s going on in, for example, satellites and components at launch. Due to the high cost and complexity, satellite vibration qualification tests are among the most monitored and carefully run tests in the world. Vibration tests are often run with hundreds of channels of simultaneous data acquisition and multi-shaker tests are often run on extremely large payloads or for a multiple degree of freedom simulation.

Ideal for testing large aerospace systems

LAN-XI DAQ

Lockheed Martin is using approximately 450 LAN-XI channels for vibro-acoustic data acquisition. Based on standard, modular, commercial-off-the-shelf PULSE LAN-XI Data Acquisition Hardware, the flexible solution allows for individual modules to be used freely – either by themselves in the lab or test-center, or alternatively mounted together in a large frame. Depending on test requirements, Lockheed Martin can take a module out of a frame and use it in the control room or in whatever way that suits the test best. This flexible solution makes it ideal for testing large structures, such as satellites and spacecraft.

The high number of channels supported, high data-sampling frequencies, tight phase matching between channels, and the ability to handle a wide dynamic range of inputs all make the PULSE solution ideal for large aerospace systems. The self-test and verification tools are dedicated to high channel-count systems, which ensure reliable performance, even in the most complex configurations.

Mission-critical collaboration

Lockheed Martin works with leaders within their fields across the world, resulting in the most advanced solutions. In this demanding environment, reliability and high performance are paramount, and comprehensive noise and vibration measurement and analysis solutions must provide accurate and fast results. Joining forces with the world leaders in acoustic and vibration testing is a successful collaboration that has been on-going for more than a decade. As Egbert Hood comments, “Noise awareness is a high priority for Lockheed Martin and Brüel & Kjær supports this and proactively helps us with the latest solutions.”

This is a partnership where both sides have benefited from sharing experience and working with the most advanced products – within challenging design and development time frames. Together, highly skilled noise and vibration experts have addressed some of the most advanced engineering needs around, tackling analysis and measurement of the most sophisticated satellites, missiles and fighters the defense industry has ever manufactured.

A multi-role fighter is designed to excel in multiple combat missions. The F-35’s roles include air-to-air; air-to-ground; intelligence, surveillance and reconnaissance; electronic attack; and command and control. Using a combination of design, tactics and technology, the F-35 has advanced stealth capabilities, making it virtually undetectable. The integrated avionics and comprehensive sensor package give pilots real-time, 360-degree access to battlefield information.

- Height: 14 ft

- Length: 52 ft

- Wingspan: 35 ft (F-35A and F-35B) and 43 ft (F-35C)

- Max. speed: in excess of Mach 1.6

- Engine: a single Pratt & Whitney F135, producing approximately 40,000 pounds of thrust in afterburner

- Weight: approximately 60,000 lb (gross)

뉴스레터를 구독하고 소리와 진동에 대한 최신 이야기를 만나보세요