In some vehicles, manufacturers may invest heavily in pursuit of a specific sound, and in others, manufacturers will be aiming for the quietest interior they can get. But as Dr Krohn (Head of Acoustics Quality Assurance for the Volkswagen factory in Kassel) pointed out: “You may want to hear the engine, but nobody wants to hear the transmission; it’s annoying to the customer.” That comment really sums up transmissions for the vast majority of drivers, but not just for sound, also for durability. The transmission is something that should just work and stay carefully in the back-ground. Unless they are manually shifting gears, people don’t even want to think about the transmission, and with the trend of vehicle interiors becoming increasingly less noisy, they especially do not want to hear it.

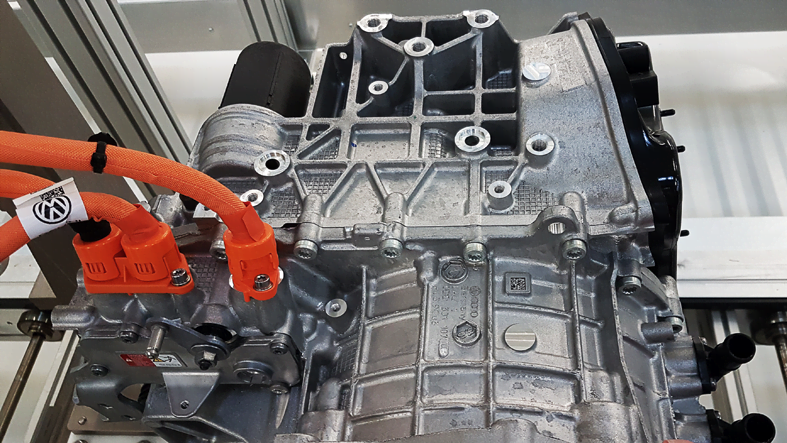

The Volkswagen plant in Kassel, Germany, is the Volkswagen Group’s largest gear and transmission production facility. They make transmissions, literally from start to finish: from milling the gears to the final transmission assembly. They produce about 17,500 complete transmissions per day, and their goal is to produce transmissions that cost-effectively satisfy customer expectations for durability, ride com-fort (including noise) and price.

Testing to increase productivity

Gears and transmissions are machine made to tolerance limits. But flaws (for example, nicks and surface ripples, or weaviness) are unavoidable and tolerance limit exceedance can happen due to tool wear, but with that kind of volume over the course of a single day, even a small percentage of substandard gears or, even worse, completed transmissions is a substantial number that must be reduced to an absolute minimum. This makes testing and finding the causes of defects and predicting tolerance exceedance necessary.

A first, knee-jerk reaction might be to assume that as complexity, quality requirements and customer expectations increase, the rigours of testing would increase and transmission quality rejections would also increase, but that is only half right. Yes, testing has become much more rigorous and fine-tuned, but the success rate for completed transmissions is better than it used to be, and, according to Dr Krohn, particularly in the last 5 years. So how do they manage to increase the testing strictures and have better end-of-line results?

Id root causes – eliminate failures

The answer, of course, lies in testing for the right reasons, establishing a control loop and identifying problems earlier and earlier in the process. Reworking a single gear pulled off the production line is not too costly, pulling a gear out of an assembled transmission is expensive, but pulling a transmission from a completed vehicle to fix that gear is prohibitively expensive and unacceptable – that vehicle actually reaching a customer, worse yet.

Testing is primarily focused on identifying durability issues and ensuring customer acceptance. Durability issues, such as nicks and surface weaviness in gears can lead to a failure in an assembled transmission (as well as added noise irritating the customer). And on top of the expected reliability, there is the ride quality and comfort that consumers have come to expect and associate with quality.

Of course, while testing for durability and customer acceptance, the outcome needs to be cost-effective. According to Dr Krohn, perfect gears and transmissions that function perfectly and produce insignificant noise, are producible, but definitely not cost-effective. At the same time, noisy vibration factories jammed into the drivetrain could be available for little more than the cost of materials. But would they even be worth that cost? Somewhere in that spectrum are transmissions that are reliable, unobtrusive and affordable. The problem is that, as expectations rise, there needs to be a way to continuously move that convergence of durability, cost and acceptance further and further to the perfection side of the spectrum.

The control loop and Rotas

Establishing a control loop with testing for each transmission family is the key element in keeping that convergence moving in the right direction. The basic elements of Volkswagen’s control loop are cycles of testing, comparison and evaluation, refining test parameters and retesting throughout the developmental stages of the production line. The stages are a preliminary group, a pre-series and the final production line. Testing is the key element, and this is where Discom enters the fray.

Discom has had a close working relationship with Volkswagen for many years. Discom’s Rotas Analysis System software is used both to test gears at the end of their production lines and also to test the completed transmissions at the end of their lines.

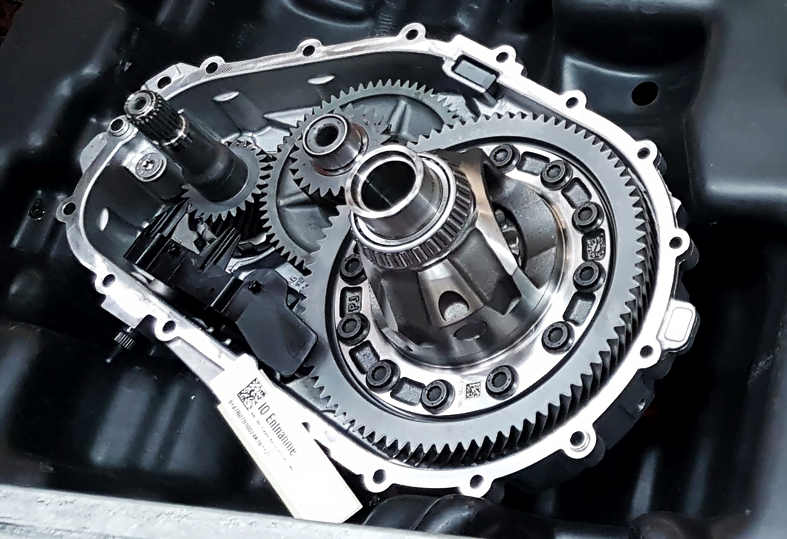

The gearset testing focuses on finding nicks, machining (spacing) issues and surface weaviness. The end-of-line transmission test simulates vehicle conditions and uses order-synchronous resampling, so the noise sources from different rotors inside the transmission can be separated.

The Rotas system consists of a latest-generation industrial computer that has been enhanced by a unique USB-based data acquisition front end specially developed by Discom. Two of the key elements of the Rotas software that are particularly beneficial to large production environments are a parameter database and a result database. Due to the order-synchronous resampling process, a rootcause analysis of the production defect is possible. The result database and associated tools in the Rotas system help to develop predictions on tool wear and related tolerance mismatch problems.

When creating a new production line, the first task is producing the ‘preliminary group’, which is around 20 pre-production transmissions. In this stage Dr Krohn’s team works with Discom to analyse data and find identifying characteristics. This is where the gears and produced transmissions will be tested on the production line with Rotas to form a baseline and begin to identify pertinent characteristics. For example, a seven-gear transmission (six forward and one reverse) would typically have around 700 characteristics (two speed ramps per gear, which works out to 50 characteristics per test step or ramp) identified by Discom (examples of characteristics include spectral values, energy values and order tracks).

Once the preliminary baseline is established, the completed transmissions are put in vehicles and tested using a mobile test system to establish correlation with test stand data. The data and drive feedback are used to refine the test limits. This is an iterative process that leads to a much more refined set of limits for the next trip through the end-of-line test stand.

The next step in the process is the ‘pre-series’, which can consist of a couple of hundred transmissions. The pre-series is a more refined version of the preliminary group end-of-line test and mobile test, with continued cooperation with Discom. The major goal at this stage is to find the subset of those characteristics that are of specific relevance for the current transmission model and where the limits are most important. In the end, out of those 700 characteristics, the Volkswagen team will identify, perhaps, 200 or so that are relevant to the particular gearset and transmission. They will continue to adjust parameters and limits, looking for that best-fit for durability, customer acceptance and cost-effectiveness.

The production line may be the final step in the production line development process, but in practice, the production line is only one long stage in the test-loop refining process. All of the data for each gear and transmission test (passing and failing) is stored and available for retrieval for later reference and analysis, within seconds. This aids in developing predictions concerning tool wear (that leads to surface ripples and tolerance exceedance, etc.) and identifying root causes for faults that can be eliminated in the future.

The flaws never stood a chance

When machining and material issues can be found early in the process, they are much less expensive to deal with, gears can be melted down and remade. But the later issues arise in the production process the more expensive they become. For example, if a transmission is assembled and there is a tolerance mismatch with some of the gears that causes extra friction and noise, the entire transmission has to be taken apart by hand, the parts checked and then recycled through the system to get rid of the mismatch. And of course, the worst case scenario is a sub-standard transmission making it into a car. The testing procedures, systems and software developed and used by Volkswagen and Discom don’t just weed out defective transmissions, they improve customer acceptance and cost-effectiveness by stopping the vast majority of problems early in the process before they can become increasingly expensive and aggravating to the end users, the customers…us.

DISCOM

For the past 20 years Discom has developed and distributed systems for acoustical quality analysis used in end-of-line testing in the automotive industry, and these systems are highly respected and used worldwide by companies in and around the automotive industry. Brüel & Kjær acquired Discom on July 26, 2016. This acquisition enables Brüel & Kjær to better support its customers by expanding its production quality testing capabilities to end-of-line analysis solutions and provides additional networks for Discom to better support customers and additional resources to facilitate adaptation to theever-evolving automotive industry.

当社ニュースレターを購読すると音とバイブレーションの世界からの最新情報を取得できます。