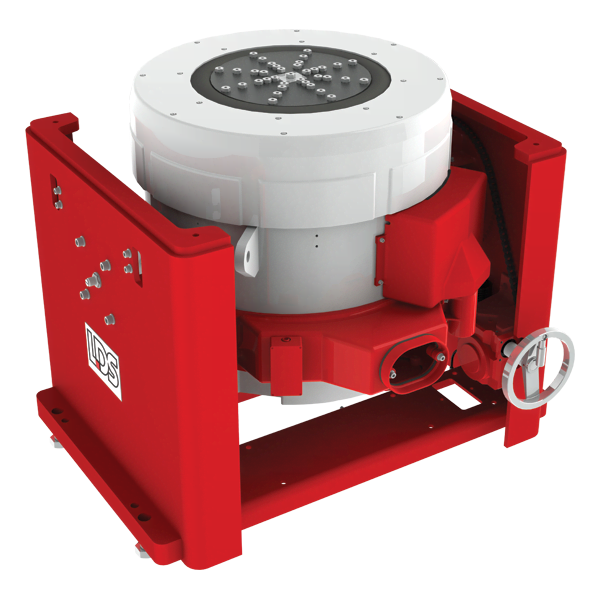

LDS V875LS

Medium-force Air-Cooled shaker

An air-cooled electrodynamic shaker used for vibration and mechanical shock testing of medium-to-large payloads up to 600 kg (1323 lb), such as automobile parts, rocket and satellite components, and electronic assemblies. It has a long stroke and peak force ratings of 35.6 kN (8000 lbf).

견적 요청하기Developed in response to our customers’ ever-growing testing needs, LDS® V875LS can reach ample maximum displacement, or stroke, while delivering generous force and velocity. This shaker is extensively used in R&D and production by the automotive, aerospace and defence, consumer electronics, and transport and packaging industries. It is suitable for high-shock tests, general stress screening, product qualification and package testing.

USE SCENARIOS

- Qualification testing of automotive parts and systems, including industry standards like ISO/TS 16949, Squeak and Rattle tests, and Road Load Data applications

- Electronic assembly and computer equipment testing

- Avionics and military hardware testing, such as Mechanical Environmental Tests AECTP 400, ISO 9000, MIL-STD and AS9000 standard tests

- Telecommunication and satellite component testing

- General stress screening, including ISO 5344, HALT, ALT and HASS

- Product and package testing, such as ISTA and ASTM 4169 tests

- Shock test applications, including Shock Response Spectrum (SRS)

- Environmental testing with AGREE chambers, Combined Environmental Reliability Test (CERT) and others

CHARACTERISTICS

The only shakers in the medium-force range capable of such long stroke, they give 76.2 mm (3 in) of maximum displacement in both vertical and horizontal modes for three-axis testing. The two available versions, V875LS-440 and V875LS-640, offer unrivalled flexibility, as they can be easily optimized for particular tests or payloads.

Both models feature interchangeable armatures, with diameters of 440 and 640 mm (17.3 and 25.2 in), respectively; this allows the mounting surface to be extended for testing oversized, bulky, or packaged items, thus minimizing the need for additional head expanders.

While a longer stroke usually results in reduced cross-axial stiffness and lower overturning moments, this has been corrected with the incorporation of a proven roller-bearing design used in other LDS® shakers.

Furthermore, the shakers have a unique armature centre-positioning system that virtually eliminates the effects of dust and debris to ensure reliability and efficiency during testing.

Standard models come mounted on trunnions equipped with LDS® Lin-E-Air suspension, which provides excellent isolation between the shaker and the building floor to allow tests to be conducted at very low frequencies.

ADDITIONAL CAPABILITIES

The V875LS shakers can be fitted with a number of options to meet the your specific needs: mounted on an air-isolation trunnion with body rotation gear box (as standard), combined with one of our oil-film slip tables to enable horizontal as well as vertical vibrations, or base-mounted for under-chamber operation.

Like the rest of the LDS® V800 series, these shakers are compatible with environmental testing equipment, including AGREE chambers. Thermal barriers are available to protect the shakers from high temperatures during these tests. Depending on the size and mass of the payloads, head expanders can also be added to increase the mounting surface and ensure that larger devices are safely and comfortably fastened for testing.

- Sine force peak

- 35.6kN

- Max random force RMS

- 35.6kN

- Max acceleration sine peak

- 112.0g

- Velocity sine peak

- 1.8mpers

- Displacement continous pk-pk

- 76.2mm

- Moving element mass

- 32.4kg

- Usable frequency range

- DC – 3.0kHz