So we rely on all instruments to be good enough. Even on space vehicles, the most accurate, critical measurement instruments give readings within an acceptable margin of error – the ‘uncertainty budget’.

It is one thing to build an instrument with the precision to do this consistently. It is another to relate the values the instrument shows to an ‘absolutely’ correct authority – the goal of calibration. But maintaining these abilities through the rough and tumble of atmospheric changes, daily knocks, and material fatigue requires regular checks, in the form of recalibration.

“For certain businesses like helicopter manufacturers, calibration is critical,” says Greta Koch, Brüel & Kjær’s Calibration Production Manager. “Accelerometers monitor their gearboxes’ health, but if the system doesn’t detect an error because it is not calibrated to measure correctly, the consequences could be catastrophic.”

Why can't an instrument measure perfectly?

Because instruments do not define what they measure, although we might think they do. Instead, they react to phenomena and compare them to their imperfect ‘memory’ of an absolute, primary standard.

The phenomena themselves exist absolutely and faultlessly. The instrument merely describes them and cannot do so perfectly because it is made of solid materials, and physical forces affect its structure and therefore its readings.

LEARN MORE

MICROPHONE TYPE 4160

Calibration is Key to Quality

For manufacturing industries, which depend on how well products are made, calibration is the key to consistently outperforming competitors on quality.

LEARN MORE

MICROPHONE TYPE 4180

Without re-calibration, end-of-line test equipment – such as at a mobile phone factory – can appear to function correctly while concealing decaying accuracy. And inaccurate tests lead to customer warranty complaints, damage to the manufacturer’s reputation, and expensive recall – along with unplanned production downtime.

Within a large organization, the design, engineering, production, and validation time of any product – from a truck to a satellite – depend on reliably relevant, timely, and accurate measurement data. Any discrepancies cause friction and delays, so the unquestionable, uniform baseline that calibration provides assists hugely with data confidence.

With less questioning, troubleshooting, and reworking, time-to-market is inevitably reduced. Meanwhile, efficiency is enhanced by fewer design changes and less wastage from false rejections of passable products.

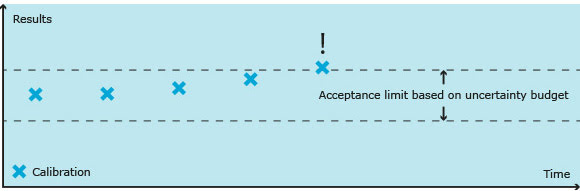

Calibration is

always performed before and after adjustments, allowing users to verify their results to date, analyze trends and see how accuracy drifts over time.

This information is used to predict when results might occur outside of the designated uncertainty budget..

Protecting Acoustic Consultants

Neglecting calibration can have consequences that resound through different businesses. Acoustic consultants make measurements that their customers depend on, both legally and economically. They can affect large decisions, like choosing the most economical windows necessary for a tower block.

An acoustic measurement on a building project can contribute to the overall noise tolerances of the building. But if the noise level inside the finished building proves too high, it can be hugely costly to rectify. And if this is due to an erroneous instrument that hasn’t been calibrated in the time specified by the relevant ISO or IEC standard, the acoustic consultant could be liable.

LEARN MORE

ACCREDITED CALIBRATION

The only defense is a legal basis for measurement integrity – accredited, traceable calibration.

Why do people skip calibrations?

Technological overconfidence

Some people think that digital instruments don’t need it, but they all do.

Legal ignorance

Some don’t realize that to measure accordingly to ISO standards or national standards, their instruments must be calibrated regularly.

Cost

Calibration requires downtime, but to skip it can create a false economy. According to a survey commissioned by Advanced Technology Services in 2008, the average cost of poor quality calibration for US manufacturers is $1,734,000 each year. Looking only at large companies that generate revenues of over $1 billion per year, the annual average is $4,000,000.

Traceability is everything

Since no instrument can measure perfectly, no measurement can be trusted unless the instrument has been recently calibrated to read within a specified uncertainty budget at a calibration lab. Then the calibration lab’s own reference instruments have to be recently calibrated to a tighter uncertainty budget, and so on up an unbroken chain to the top laboratory in any jurisdiction: the primary laboratory.

This traceability hierarchy is fundamental. The only defense against an endless spiral of relativity is the ability to trace – through a secondary lab – every measurement anyone makes anywhere to one of these primary labs.

As Henning Ploug, Calibration Manager at Brüel & Kjær says, “The validity of this entire chain depends on the integrity of the instrument above it. Any error can mean questionable results, and can extend damage exponentially out through different businesses.”

IF A PLANE IS CERTIFIED to carry less cargo, it can mean millions in lost earnings.

Inaccurately calibrated equipment could result in the take-off noise level being measured at the limit, when in fact it is 0.1 dB below. This leaves unused noise potential, which would allow more power – permitting more weight.

Secondary Laboratories

These workhorses of the calibration eco-system perform normal calibration on a huge amount of instruments – over 10,000 calibrations per year in Brüel & Kjær’s Denmark lab alone, on 1500 different types of instruments. Here experts rigorously check important parameters in controlled atmospheres, relating all measurements to their own reference instruments (highly accurate microphones and accelerometers).

Most measurement procedures are dictated by IEC and ISO standards, for which secondary labs must keep over five years of records. Most instruments should be recalibrated every year, or even more often. It depends on the level of use and temperature fluctuations they receive since more wear, tear and dust will affect accuracy sooner.

Calibrations take about a week because of the rigorous procedures needed. Nothing can be rushed, and instruments must first acclimatize to the precise humidity and temperature, and stabilize for between four hours for basic instruments, up to 24 hours for primary reference microphones.

Partly to save shipping and customs delays, Brüel & Kjær has 12 secondary labs around the world, making over 30,000 calibrations per year. These are all legally verified in the countries that require it and certified by national accreditation bodies – the highest authorities in their respective countries. These bodies check procedures, record keeping, and competence.

Above all, they ensure the measurement chain remains unbroken up to the highest authorities of all: Primary laboratories.

Primary Laboratories

Primary laboratories create, maintain, and disseminate standards to the rest of the measurement world; to secondary labs and organizations that need a very high degree of accuracy. Aircraft manufacturers are one example.

“For them, a 0.1 dB error can mean serious costs,” says calibration expert Erling Sandermann Olsen. “If an aircraft’s noise level exceeds the stated specifications, they can get heavy fines from airports. And if an engine received an incorrect noise certification, it could prevent aircraft from operating at some airports entirely.

Danish Primary Laboratory of Acoustics (DPLA)

Denmark has one of the most active primary calibration laboratories for acoustics and vibration in the world, the Danish Primary Laboratory of Acoustics (DPLA). The laboratory is partly run by Brüel & Kjær, although it’s a completely separate entity.

At DPLA, only reference transducers are calibrated, such as reference instruments from secondary labs, and Brüel & Kjær’s own production line testing equipment – which are compared to primary reference instruments.

Some organizations, especially aircraft manufacturers, have so many instruments that they can’t afford the time to send them away and invest in their own secondary calibration lab. These, as well as other secondary labs worldwide, are served by Brüel & Kjær’s commercially available reference instruments and calibration equipment. Through such Brüel & Kjær reference instruments, a very large share of the world’s sound and vibration measurements are traceable to DPLA.

当社ニュースレターを購読すると音とバイブレーションの世界からの最新情報を取得できます。