INDUSTRY SOLUTIONS FOR YOUR MEASUREMENTS

Brüel & Kjær is known for providing the highest quality products and systems for sound and vibration measurement — a reputation we have built over seven decades. With solutions we combine our industry knowledge with products, service and suppport to help you achieve the best result for your project.

ブリュエル・ケアーは、70年以上にわたり、音と振動の測定において最高品質の製品を提供してきました。当社では近年、設計から導入、運用に至るお客様の製品のライフサイクル全体にだけでなく、完全な測定チェーンをサポートすることにリソースと知識を重点的に投下しています。さらに、完全なターンキーソリューションやスタンドアローン製品を提供することも可能です。

完全な製品ライフサイクルをサポート

設計、開発から製造、展開、運用、環境へのコンプライアンスに至るまで、以下の4つの方法でお客様をサポートいたします:

- 製品性能の向上

- 市場投入までの時間短縮

- 品質保証の改善

- 法令順守

何よりも重要なことは、私たちは製品とサービスのワンストッププロバイダーとして、音響振動のトータルソリューションだけでなく、お客様のニーズに合わせて拡張可能なエンジニアリングサービスをご提供できます。

- Enhance your product performance

- Reduce your time to market

- Improve your quality assurance

- Ensure legal compliance

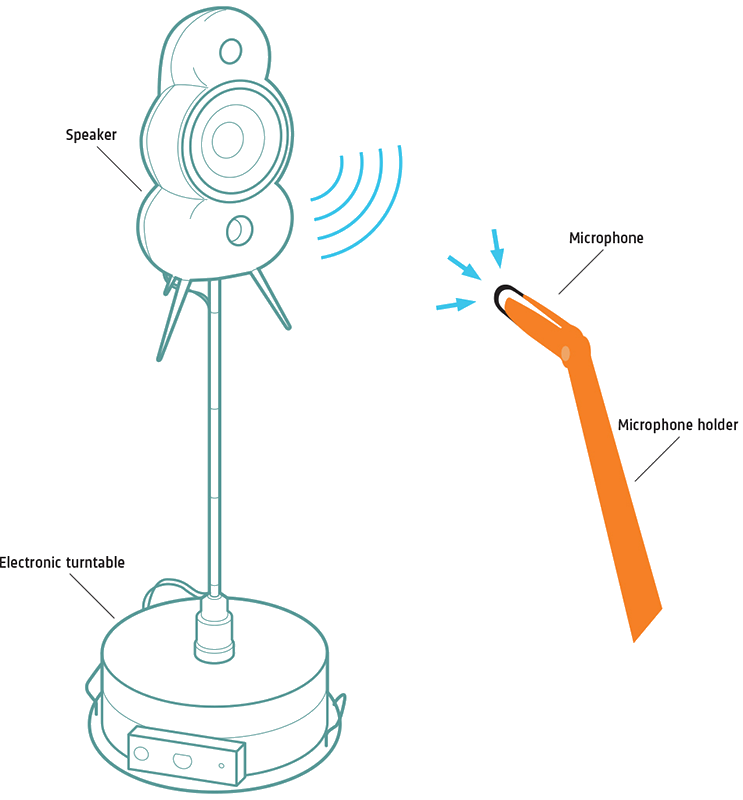

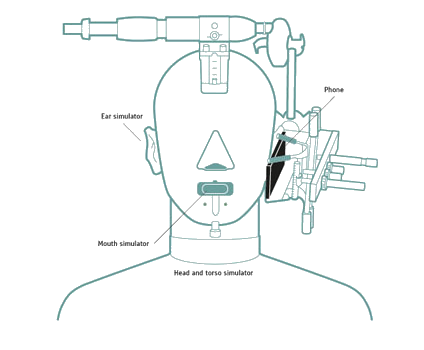

Telecom and Audio Solutions

Manufacturers of electroacoustic equipment such as loudspeakers, microphones, telephones, headsets and hearing aids deliver high‐quality acoustic designs by continuously innovating their products and processes.

Acoustic performance has become increasingly important as users demand high‐quality audio in every situation, and whether reproducing sound or transmitting speech. Measuring and documenting acoustic performance is therefore, a key element in the product improvement process, during both its development and manufacture.

Brüel & Kjær has a long tradition of close connections within the fields of telecommunications and audio, pioneering many methods that are now standard practice all over the world. Today, based on our accumulated knowledge and experience, we offer a variety of electroacoustic test systems, audio analyzers, and transducers for electroacoustic applications.

Electroacoustic Test Solutions

Audio Analyzers

These analyzers offer a variety of analysis methods including traditional sine testing (using SSR and TSR), spectrum analysis (using FFT and CPB) for testing real speech, and perception‐based testing. In combination with the hardware, Brüel & Kjær supports the audio engineer achieving reliable acoustic measurement results.

In addition to measurement and analysis, our analyzer platform offers tools to automate testing, as well as reporting and data management tools for easy management of measurement data.

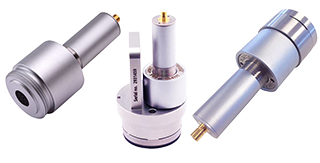

Acoustical Transducers

With our transducers, we deliver standardized testing of phones, hearing aids, headphones, headsets, earphones, loudspeakers, receivers, and other devices. All Brüel & Kjær transducers contain information about their sensitivity. When connected to the analyzer this information is automatically transferred to the analyzer, securing that the right setting is applied for the measurement task.

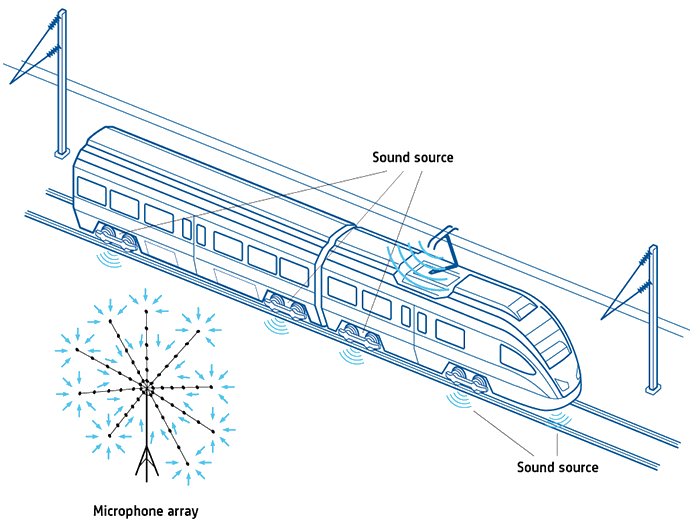

Automotive and Ground Vehicle Solutions

Passenger vehicles such as cars, trucks, motorcycles, buses and

trains continuously need to be more exciting and pleasant,

while becoming safer and emitting less noise.

Thanks to

technology, engines are quieter and vehicle bodies are better

insulated. For the most part, cars are only noisy at high speeds

or during acceleration when the engine roars into life. As the

speed increases, the noise mix produced by the tyres, chassis

and wind intensifies. For some manufacturers, the amount and

character of this phenomenon is desirable, for others, less so.

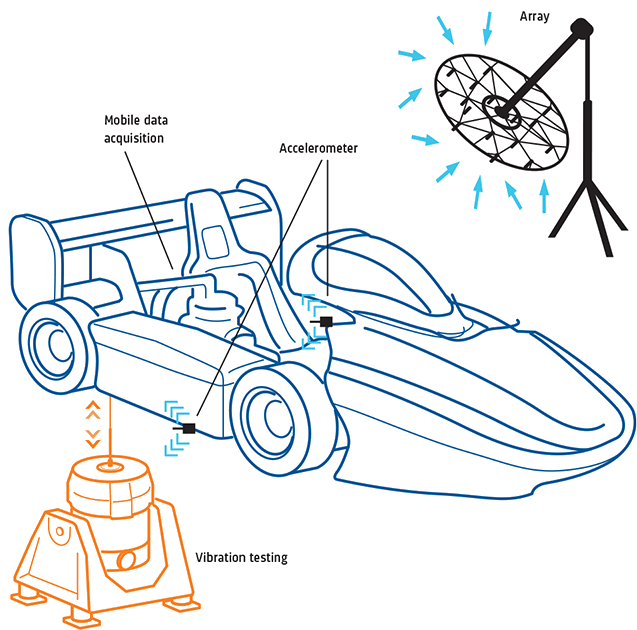

Locating and identifying noise sources, creating and correcting designs, as well as ensuring company, industry and legislative standards are key to achieving the desired results. This makes noise, vibration and harshness (NVH) testing key to vehicle manufacturers who want to establish and maintain a competitive advantage.

Brüel & Kjær’s expert knowledge of the industry, combined with extensive experience of customer‐driven projects, allows us to cover the whole vehicle NVH development process. Our solutions range from vehicle NVH software and simulators in partnership with VI-grade, enabling target setting, to spherical beamforming for 360‐degree noise mapping.

Interior NVH

Time Domain SPC enables engineers to calculate, listen to, and modify individual contributions to the vehicle occupants (both airborne and structure‐borne), and assists with design and validation of programme NVH targets.

Sound Engineering

With NVH Software auralising NVH data and providing advanced sound evaluation techniques, you can efficiently communicate NVH targets to non‐experts before physical prototypes are available. For NVH simulation, we offer comprehensive simulation to evaluate vehicles, and even benchmarking of competitive vehicles under real driving conditions together with VI-grade.

Transducers used in Automotive

Powertrain Testing

Brüel & Kjær provides efficient powertrain testing:

Brüel & Kjær provides efficient powertrain testing:- Very high‐temperature triaxial accelerometers

- Crankshaft angle analysis software

- for measuring sound power versus RPM

- Holography systems for locating noise sources and measuring partial sound power versus RPM and crank angle

- Wide band noise source identification systems customized to fit engine test cells

- Switching noise analysis, transient analysis, high‐frequency beamforming, for measuring in unknown sound fields

- Vibration testing of large batteries

Structural Analysis

Our structural dynamics suite helps improve the dynamic behaviour of any structure. Our solutions include operating deflection shapes analysis covering the full set of methods (frequency, order, time), classical modal analysis with a wide range of powerful curvefitters, and operational modal analysis.

Squeak and Rattle

Our unique equipment range ensures that automotive components and interiors are durable and free from noise and supports industry‐standard QA practices for squeak and rattle vibration testing. Solutions include:

- Low‐noise shaker systems

- Sound quality analysis software

- Array‐based systems for quick localization of noise sources

Wind Tunnel Testing

When combined with a spherical beamformer inside the vehicle, a detailed noise cause‐effect relationship is achieved using minimal testing time.

Exterior Noise

As community regulations put ever tighter restrictions on noise emission, our vehicle pass‐by solutions offer complete support and compliance with the latest standards. Adding moving source beamforming enables noise source localization and troubleshooting during measurements. Our Indoor Pass‐by Noise System enables efficient comparison of design alternatives.

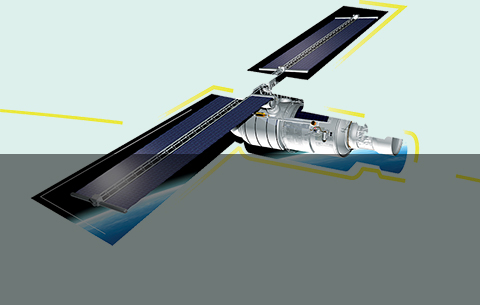

Aerospace and Defence Solutions

Ever‐shortening design and development time frames of modern aerospace and space programs demand 'right‐first-time' engineering. While the aerospace sector is seriously concerned with aviation efficiency and the requirements of environmental directives, defence industry manifactures have the added concerns of ensuring reliability and high performance of military systems, often under extreme conditions.

Recognizing that high‐quality, goal‐focused, time‐ and cost-efficient testing is critical to meeting program milestones, Brüel & Kjær addresses today’s engineering needs by providing quality sensor solutions.

Whether turnkey solutions or dual‐use application needs, Brüel & Kjær provides the aerospace and defence sectors with transducers that comply with common industry standards:

- BS EN ISO 9001:2008

- EN 9100:2009

- AS 9100 Rev. C

Brüel & Kjær’s quality management system is applicable to development, production, sales, and service of customer-specific transducers.

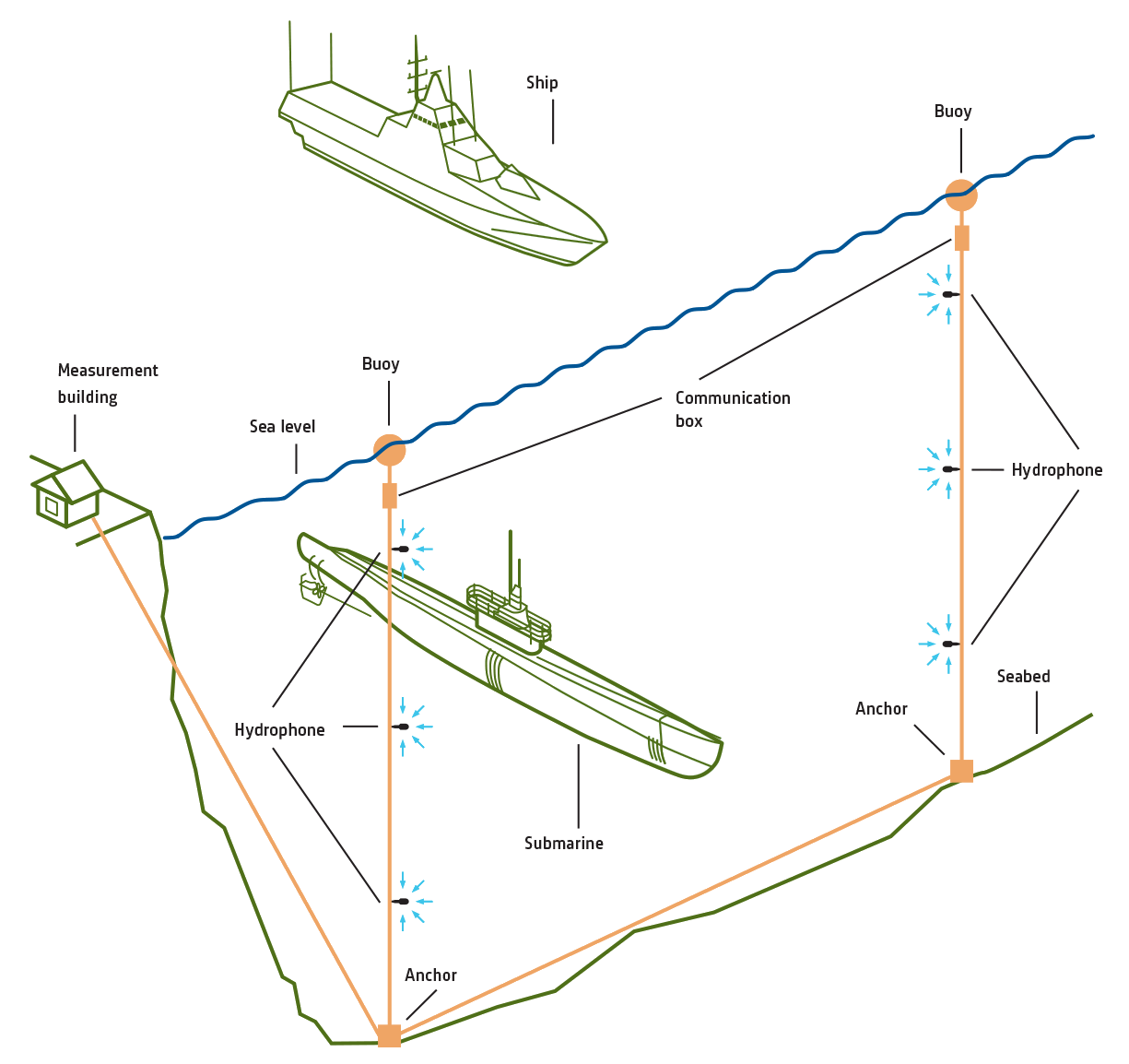

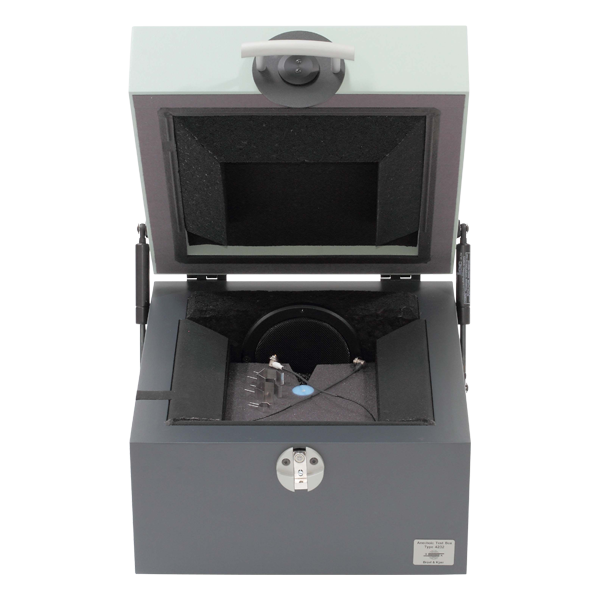

Acoustic Test Suite

Whether your interest is exterior or interior noise, our acoustic test

suite provides data acquisition and assessment systems to combat

your noise problems by optimizing noise identification, improving

sound quality, and ensuring compliance with environmental

legislation.

Our acoustic test solutions include:

- Noise source mapping and location

- Wind tunnel and flight testing

- Engine and aircraft certification

- Acoustic material testing

- Cabin comfort and occupational health

- Ramp noise and sonic boom

- Underwater acoustics

- Hull monitoring

- Acoustic stealth and noise signature management

Transducers used in Aerospace and Defence

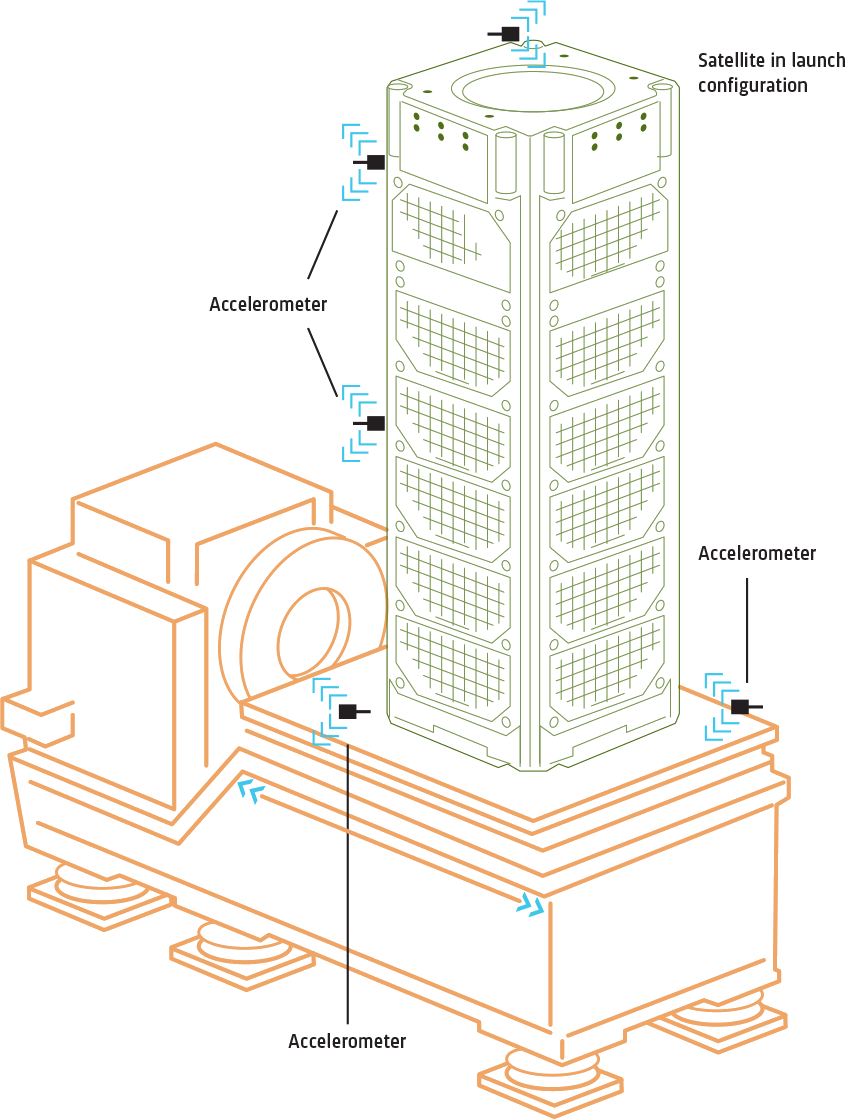

Environmental Test Suite

Reproducing realistic operational conditions in the laboratory is essential for qualifying the real‐life integrity of structures to ensure durability.

Reproducing realistic operational conditions in the laboratory is essential for qualifying the real‐life integrity of structures to ensure durability. Whether for billion‐dollar satellites, launchers, aircraft, instruments or structures, our comprehensive vibration test solutions provide a wealth of environmental test systems for:

- Durability and acoustic fatigue testing

- Classical and pyro shock

- Sine, random, sine‐on‐random, random‐on‐random testing

- Shock response spectrum

- Kurtosion

- Field data replication

Rotating Test Suite

Vibration analysis of rotating machinery provides valuable information on engine health, reliability, and performance. From R&D and production test-cell applications to on‐ground maintenance, our vibration measurement and analysis systems provide you with powerful machine analysis tools designed for:

- Vibration analysis, monitoring and diagnostics

- Vibration data acquisition and analysis in engine test cells

- On‐ground vibration check of aircraft engines

- Order analysis and autotracking

- Balancing and trim balancing

- HUMS transducers

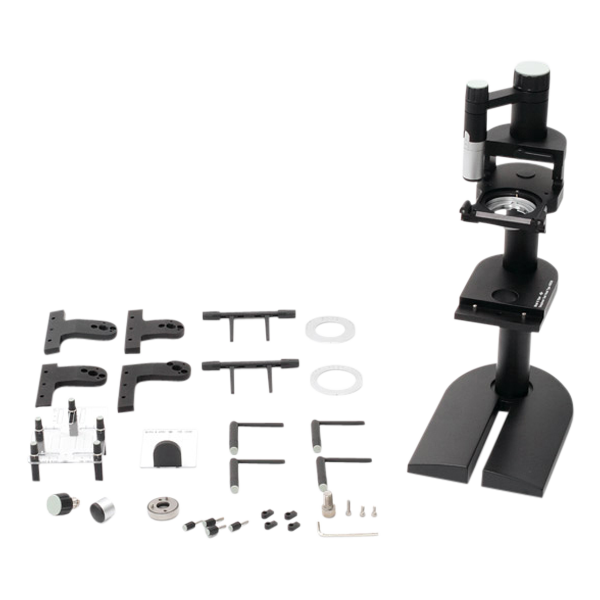

Structural Test Suite

Structural dynamics testing is vital to understand and optimize the inherent dynamic properties of structures, to ensure reliable and safe operation.

Structural dynamics testing is vital to understand and optimize the inherent dynamic properties of structures, to ensure reliable and safe operation.Our structural test suite offers complete systems for controlled excitation testing, real‐life operational testing, and test‐FEA integration – from the smallest components to the largest assembled structures, we provide solutions for the following applications:

- Operating Deflection Shapes analysis

- Operational Modal Analysis

- Classical Modal Analysis

- Normal mode testing

- Structural dynamics modifications

- Model correlation and updating

Brüel & Kjær is unique in the sound and vibration industry, providing all the elements for the most technologically advanced and complete sound and vibration solutions designed to save time and eliminate errors in the measurement process.

Brüel & Kjær is unique in the sound and vibration industry, providing all the elements for the most technologically advanced and complete sound and vibration solutions designed to save time and eliminate errors in the measurement process. In fact, Brüel & Kjær equipment and knowledge are behind thousands of achievements, from high-performance cars and smartphones to satellites and beyond – even helping with the Mars rover landings.

For further details or questions on our solutions and product types, specifications and price, please get in touch with your local Brüel & Kjær sales representative.

当社(ブリュエル・ケアー)へのお問い合わせについて

.ashx?h=150&w=150&hash=328A32C19416F65D49AE328C4588A7209ED7FEAC&la=ja)