Transducers FOR SOUND AND VIBRATION

Transducers are a core part of Brüel & Kjær’s business and have been for more than 70 years. The quality of our products is renowned worldwide and is the result of our unique experience and knowledge in the production, development of our products. Each transducer is subject to meticulous testing and quality control, ensuring you get the industry-leading accuracy, performance, and stability across any application.

What is a Transducer?-

Acoustic Transducers

Our acoustic transducers include measurement microphones, hydrophones, acoustic calibrators, and sound source - recognized by engineers worldwide for accuracy and reliable measurements.

-

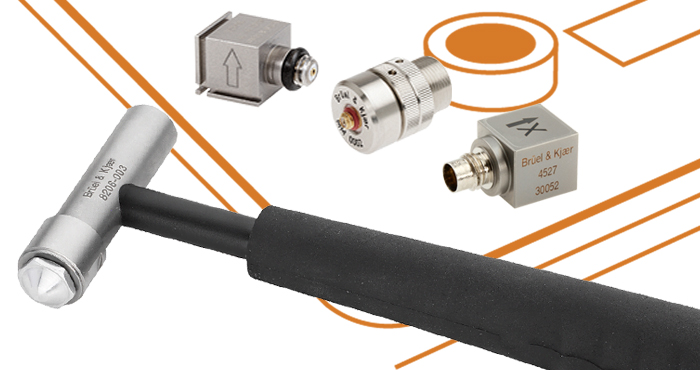

Vibration Transducers

Vibration transducers and sensors featuring accelerometers, force transducers, tachometer probes, and vibration calibrators providing advanced sensor measurement technology.

-

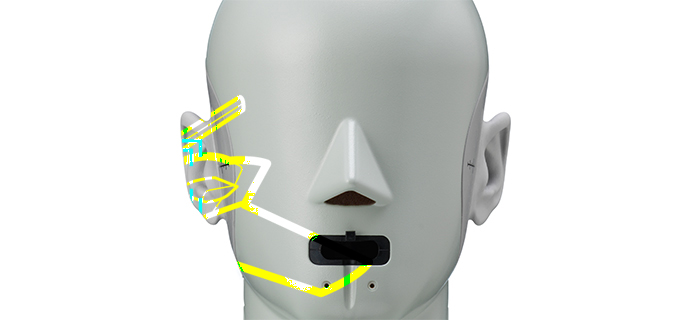

Head and Torso Simulators / Ear Simulators

Head and torso simulators, and ear simulators are used to measure and document standardized acoustical performance during development and manufacturing of new products.

-

Signal Conditioning and Amplification

Signal conditioning and amplification drastically improves the performance and reliability of measurement systems. Brüel & Kjær deliver the highest quality CCLD, Charge, and Multi-Pin Signal Conditioners.

SEVEN

KEY FACTS & FIGURES

ONE

Transducers are a core part of Brüel & Kjær’s business – they always have been, for more than 60 years.

TWO

Brüel & Kjær continually invests in state-of-the-art production and test equipment

THREE

Each transducer is subjected to between five and ten test functions during its manufacture to ensure accurate sensitivity

FOUR

The parameters of prototypes are thoroughly tested and verified against the FEM model and the requirement specification

FIVE

After the production process is completed, the key parameters of every accelerometer are 100% tested to check that its performance is within specification

SIX

Many companies produce transducers but it is our attention to testing and quality control at all stages of the production process that makes the difference

SEVEN

Brüel & Kjær is accredited to ISO 9001 and EN 9100

WHAT IS A TRANSDUCER

A transducer is a device that converts energy (electrical signals is a form of energy) from one form to another so that the desired characteristics of the input energy can be read at the output signal.

Transducers are a vital first link in your measurement chain.

Transducer sensitivity can be stated in electrical quantity/physical parameter (for example, Picocoulomb/m/s2) or physical parameter/electrical quantity (such as Pascals/Volt).

TRANSDUCER VS SENSOR

The terms transducer and sensor are in many cases used interchangeably.

Both a sensor and a transducer can respond to changes in a physical phenomenon (like temperature or pressure) and provide a signal that can be measured using appropriate instrumentation. However, they can be very different devices with notable differences in characteristics.

- A sensor is a more generic term and may be used to describe an entire ‘system’ for documenting a physical phenomenon (like a thermometer), or just the sensing part of a bigger system ( like photosensors in a camera).

- A transducer - narrowly defined - is a device that responds to changes in a physical phenomenon and converts it into a measurable electrical phenomenon or the inverse.

TYPES OF TRANSDUCERS

There are many transducers types and equally many measurement applications.

Whether you measure electrical signals, high-frequency acceleration (HFA), or sound waves, our transducers stand on the front line and provide you with the full scale of raw data needed to make informed decisions. As an example, our sensors and airborne amplifiers are being used to provide critical flight data for a rocket's onboard telemetry. In situations like these, it is absolutely vital that the data is trustworthy.

The measurement applications range from the development of quieter, safer cars, to ensure that an aircraft and its engines are totally reliable and environmentally friendly and that household appliances have low levels of noise and vibration.

The Brüel & Kjær types range from industry-leading measurement microphones, and hydrophones, to sound sources (or loudspeakers and amplifiers)designed for acoustic measurements, to force sensors, impact hammers, and our extensive range of accelerometers for vibration measurements.

HBM Test and Measurement market-leading strain, force, load and pressure sensor technology provide accuracy in a wide range of measurement applications.

LEARN MORE

> HBM Test and Mesurement

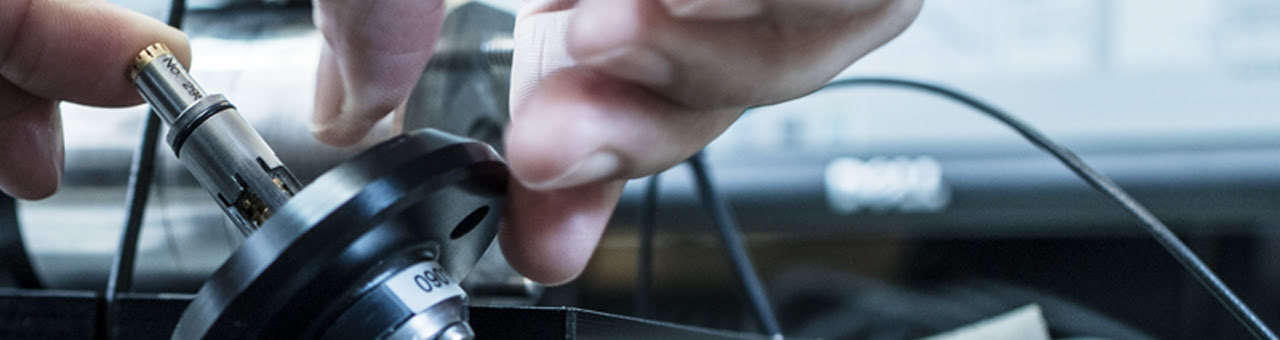

DEVELOPMENT, PRODUCTION, AND TESTING

Brüel & Kjær has invented many of the technologies used in most today’s accelerometers and microphones. It is our firm conviction that technology has no limits. If we can imagine it, we can develop it.

In production, every Brüel & Kjær product is thoroughly tested to ensure that its performance is within the specified parameters. All components, whether from sub-suppliers or manufactured, are subjected to rigorous inspection. The inspection takes the form of physical and dimensional control systems to ensure conformity to specifications and quality, as reflected in our status as an ISO 9001 and EN 9100 certified company.

With ultrasound, components are inspected and then cleaned in a demineralized water and soap solution. The parts are then dried using compressed air and placed in an oven to remove any traces of humidity. A unique process is then applied to clean the electronic components. On average, we conduct between five and ten separate test procedures together with individual calibration and validation before shipment.

Brüel & Kjær products are made with the utmost care and tested in extremely harsh environments. You can follow the process in this video showing the making of Type 4966 Free-Field Microphone:

CALIBRATION: ACCURACY AND RELIABILITY

We perform an individual calibration before shipping. Our unique status as the primary Danish standards lab reduces our traceability steps and uncertainty in measurement sensitivity.

The information we gather when testing and calibrating is detailed in our product datasheets, providing information on device sensitivity to external inputs together with any additional specifications.

Calibration is performed in our own laboratory using a technique based on FFT analysis.

This provides the needed resolution to detect certain types of problems

that are hard to identify in other systems.

LEARN MORE

> CALIBRATION SERVICES

CUSTOM TRANSDUCER DEVELOPMENT

At Brüel & Kjær, we don’t just design, manufacture, and develop transducers. We are in the business of innovation and always have been. Many of our employees are world-renowned experts, frequently speaking at conferences, presenting papers at seminars, and advising on

new standards.

Sometimes a measurement situation requires a solution that cannot be met by existing Brüel & Kjær products. To effectively satisfy the needs of our clients, we have a procedure for efficiently handling requests for customized products.

Minor modifications are handled with ease and at low cost, whereas major or new items requiring substantial engineering, will need technical and economic assessment.

WANT TO KNOW MORE?

For further details of the range, availability, and price, please use the link below to get in touch with your local Brüel & Kjær representative.

Talk to your local Brüel & Kjær representative today!